Building structure system of fabricated low-energy-consumption house

A technology of building structure and low energy consumption, which is applied to building components, building structures, buildings, etc., and can solve problems such as high construction costs, complicated procedures, and difficult construction of external wall insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

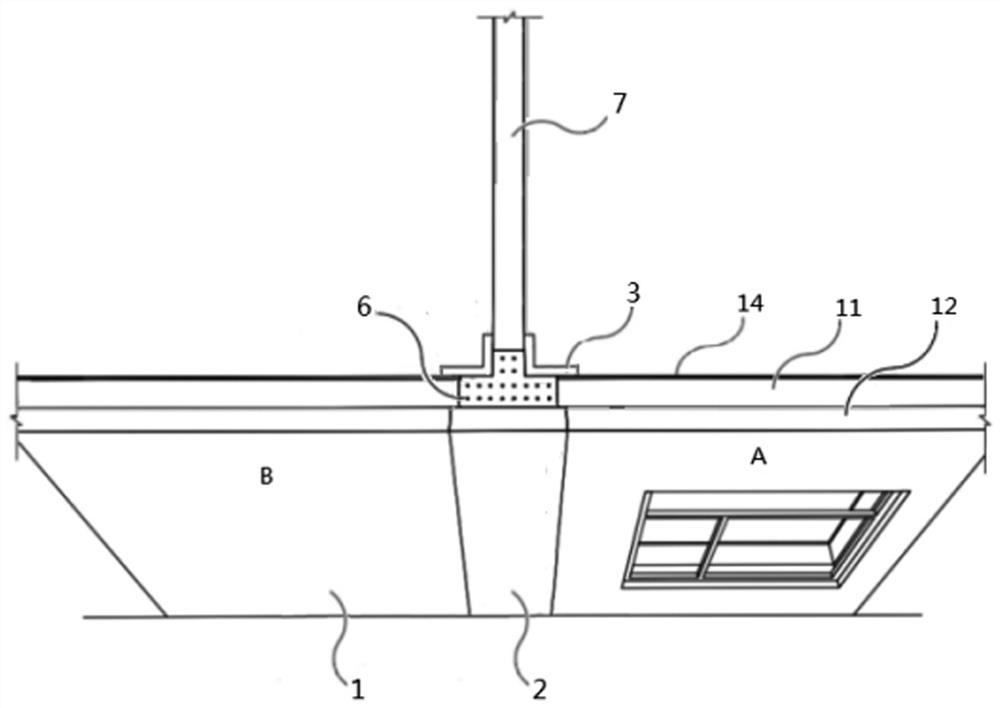

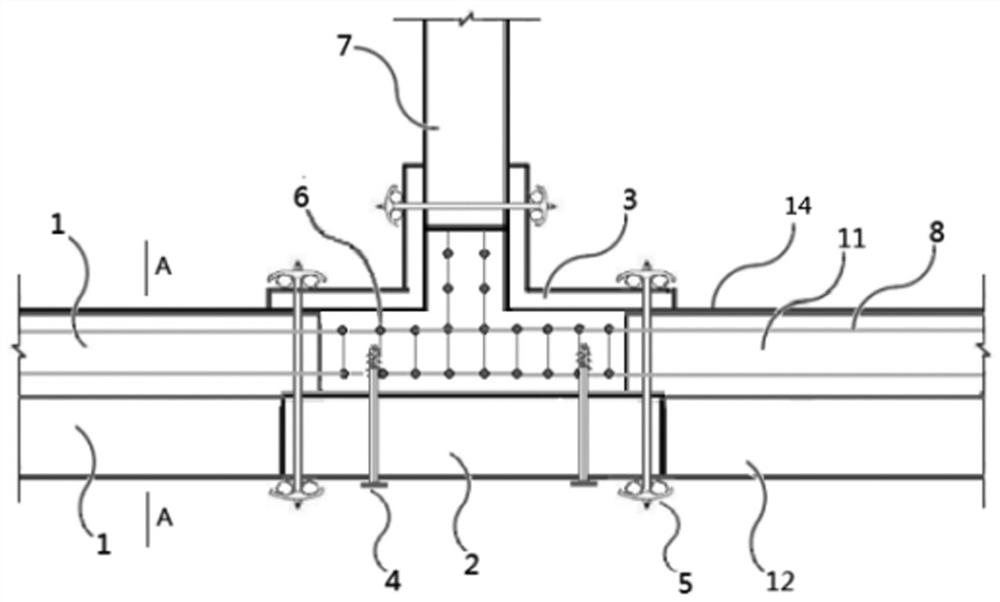

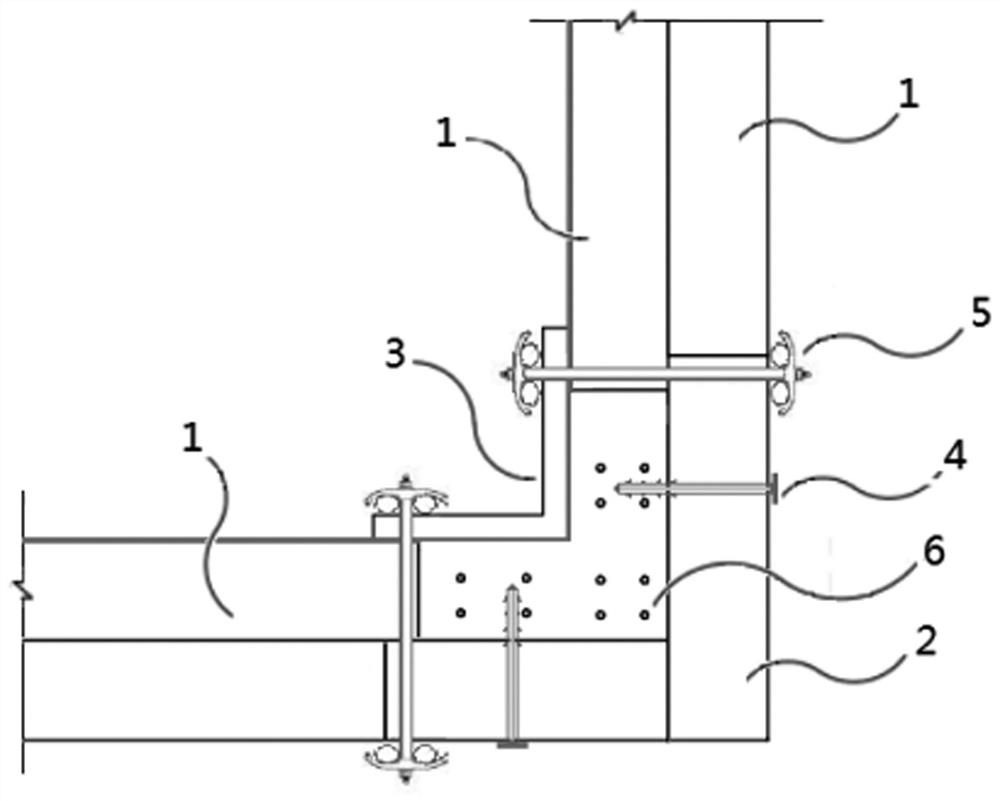

[0047] as attached Figure 1 to Figure 11 As shown, a building structure system of a prefabricated low-energy house, including: composite wall panels 1, non-dismantling outer formwork 2, inner formwork 3, thermal break bridge anchors 4 and connectors 5;

[0048] The composite wallboards include: non-load-bearing composite wallboards and load-bearing composite wallboards;

[0049] Such as Figure 4 , 5 , 6, the non-load-bearing composite wallboard includes: thin-walled light steel skeleton 11, insulation board 12, Ozon board 13, cement fiber board 14, lightweight concrete 15 and thermal break bridge anchor bolt 4, the described The thin-walled light steel frame 11 is riveted by C-shaped, U or rectangular cold-formed thin-walled light steel, and the thermal insulation board 12 is anchored on the outer rib plate of the thin-walled light steel frame 11 through the heat-breaking bridge anchor bolt 4 , the Ozon board 13 is strip-shaped, consistent with the width of the rib plate ...

Embodiment 2

[0069] Such as figure 2 , Figure 11 As shown, the composite wall panel 1 is supported and fixed according to the design position, and the structural steel bar 6 is connected. The thermal break bridge anchor bolt 4 passes through the non-demolition external formwork 2 and is connected with the structural steel bar 6. The said non-demolition external formwork 2 and the inner formwork 3 are connected to each other through connectors 5, and are connected to the composite wallboard 1 by means of connectors 5 by relying on the staggered corners provided on both sides of the composite wallboard 1, and the inner template 3 is connected to the interior of the building. Wall 7 is connected, and concrete is poured in the enclosed cavity to form structural beams, columns, and shear walls. Refer to Figure 11 , node A is an L-shaped shear wall structure, node B is a T-shaped special-shaped column structure, and node C is a T-shaped short-leg shear wall structure. Reinforced concrete sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com