Drill bit device of multifunctional core drilling machine and construction method

It is a multi-functional technology for drilling coring, which is used in the extraction of undisturbed core devices, drill bits, drilling equipment, etc., and can solve the problems of easy deviation of the drill bit, inability to ensure the verticality of the drill hole, and sticking of the drill bit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

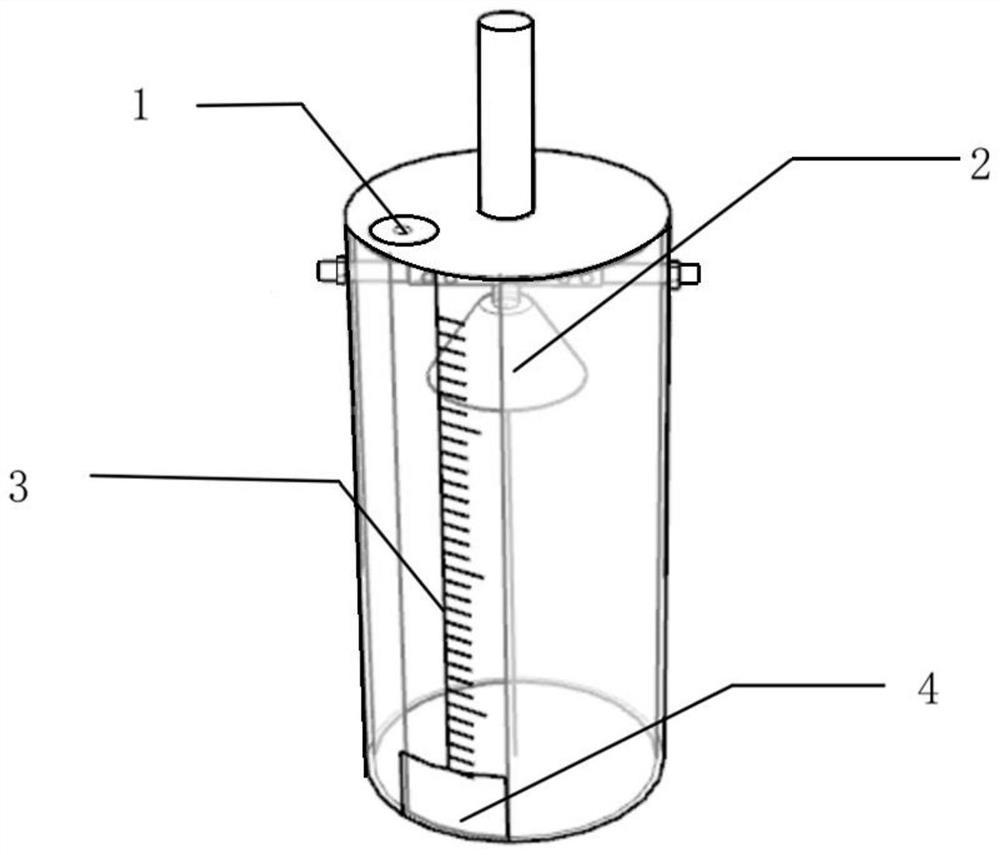

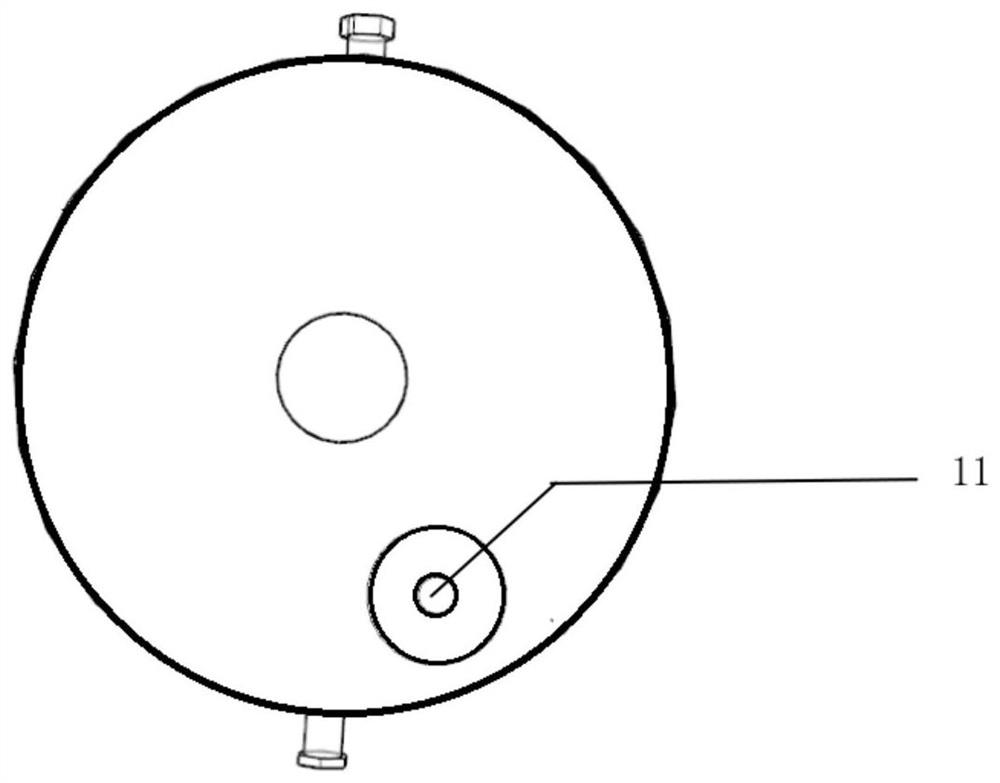

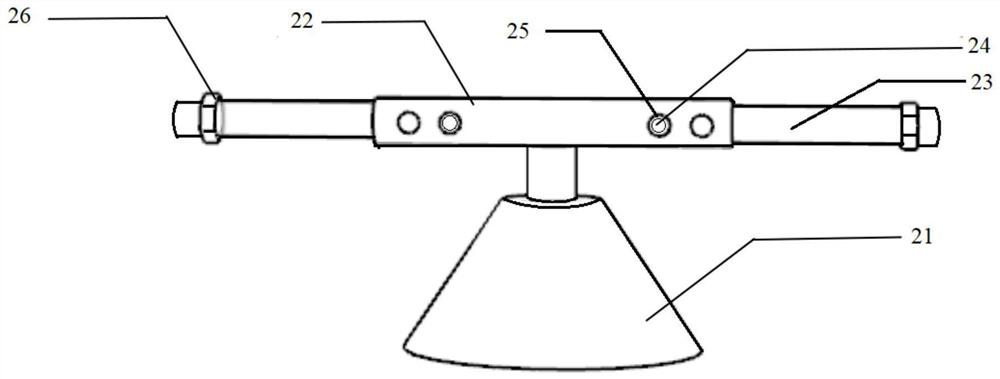

[0035] see figure 1 , the present invention provides a multi-functional drilling coring machine drill device, which includes a drill bit, a level adjustment mechanism 1, a soil core suction mechanism 2 and a scale measurement mechanism 3, the top wall of the drill bit is provided with a level adjustment mechanism 1, the drill bit A soil core suction mechanism 2 is arranged inside, and the soil core suction mechanism 2 includes a T-shaped operating rod and a suction cup 21 arranged at its lower end. Out of the through groove, and fixed on the side wall of the drill bit by a locking mechanism, the side wall of the drill bit is also provided with a scale metering mechanism 3.

[0036] When the above-mentioned drill bit device is in use, firstly, the drilling operation is completed to obtain the concrete soil core separated from the road surface; secondly, by controlling the T-shaped operating rod to slide downward along the vertical groove on the side wall of the drill bit, the s...

Embodiment 2

[0045] The present invention provides a kind of construction method utilizing the drill bit device of multifunctional drilling coring machine, and this method comprises the following steps:

[0046] S1. Move the T-shaped operating lever up to the highest point, and then lock and fix it;

[0047] S2, use the level adjustment mechanism 1 to adjust the drill bit device to vertical;

[0048] S3, carry out the drilling operation, when the drilling depth reaches the specified scale of the scale metering mechanism 3, stop drilling;

[0049] S4, cancel the fixation of the soil core suction mechanism 2, and move down the T-shaped operating rod until the suction cup 21 sucks the soil core;

[0050] S5. Move up the T-shaped operating rod, drive the soil core to move up to the highest point, and lock and fix the T-shaped operating rod;

[0051] S6, lift up the drill bit device, and take out the soil core and the drill bit device together.

[0052] Preferably, in step S1, before lifting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com