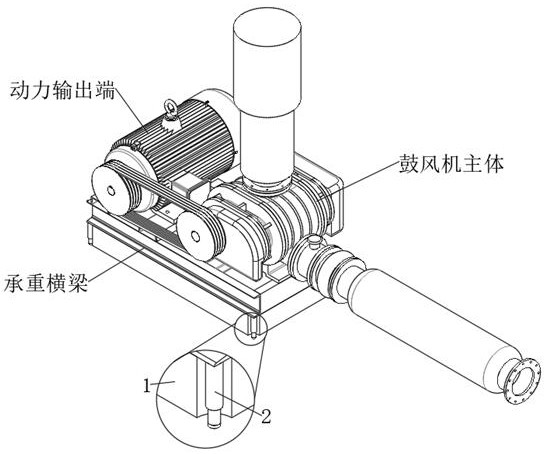

Contact type damping device for Roots blower

A technology of Roots blower and damping device, which is applied to components, springs/shock absorbers, shock absorbers, etc. of pumping devices used for elastic fluids, and can solve the impact of Roots blower working environment, shock absorption and noise reduction measures Inappropriate, affecting the shock absorption effect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

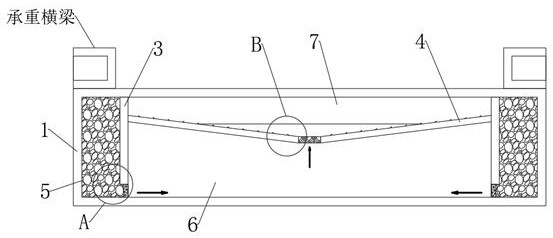

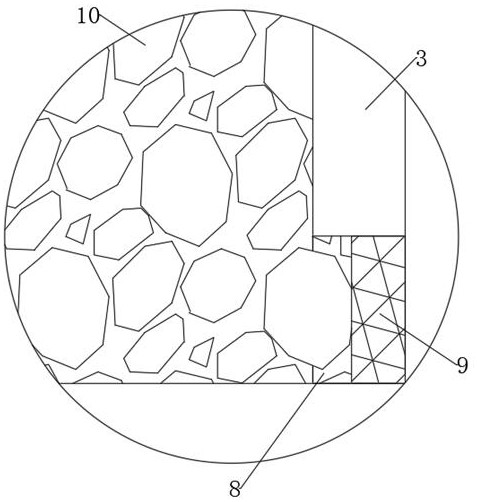

[0040] see Figure 1-7 , a contact damping device for Roots blower, including an elastic shell 1 fixedly connected to the lower end of the Roots blower, a pair of longitudinal partition plates 3 are fixedly connected inside the elastic shell 1, and the two longitudinal partition plates 3 are connected to each other. One end close to each other is fixedly connected with a horizontal partition 4 that matches each other, and the ends of the two horizontal partitions 4 away from the longitudinal partition 3 that are connected to themselves are all inclined downward, and the longitudinal partition 3 and the horizontal partition 4 will be connected to each other. The space in the elastic shell 1 is divided into three parts: the shock absorbing chamber 5, the transition chamber 6 and the buffer chamber 7. The shock absorbing chamber 5 is located outside the transition chamber 6 and the buffer chamber 7, and the buffer chamber 7 is located on the upper side of the transition chamber 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com