Heat storage electric heating device adopting power frequency induction heating and manufacturing method

A technology of induction heating and heating circuit, applied in the fields of materials science, electromagnetism, and heat transfer, which can solve the problems of long heating time and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

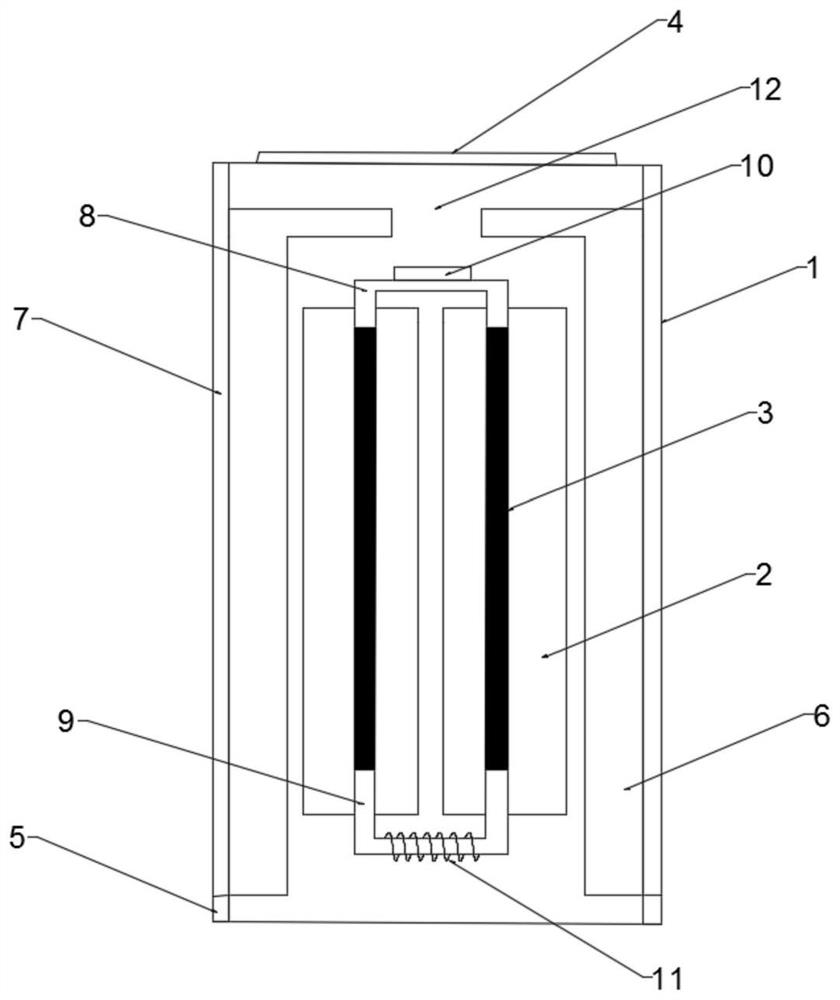

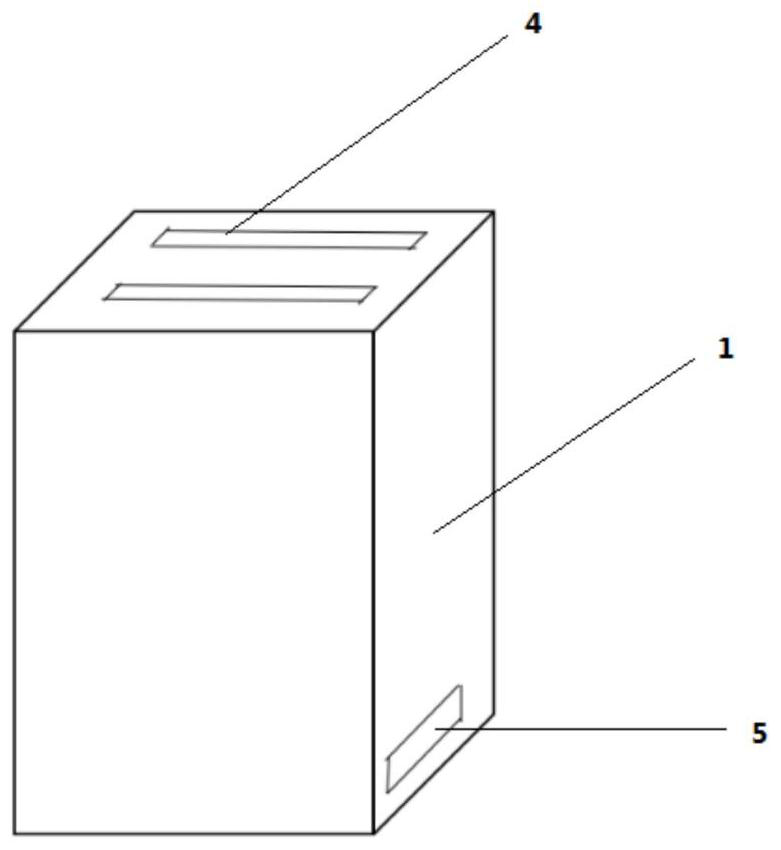

[0033] see figure 1 , this embodiment provides a heat storage electric heating device adopting power frequency induction heating, comprising a housing 1, an air outlet 4 is provided at the upper end of the housing 1, two air inlets 5 are provided at the lower end of the housing 1, and the outlet A plurality of ventilation channels 12 are formed between the tuyere 4 and the two air inlets 5, and a heating device and a plurality of heat storage structures 2 are arranged inside the casing 1, and the heating device includes two parallel cylindrical metal Rod 3, the upper ends of the two cylindrical metal rods 3 are connected by a first connector 8, the lower ends of the two cylindrical metal rods 3 are connected by a second connector 9, and the second connector 9 is wound There is a coil 11, the coil 11 is connected with a heating circuit, and two cylindrical metal rods 3 are connected with the first connecting body 8 and the second connecting body 9 to form a closed magnetic chan...

Embodiment 2

[0045] see figure 1 and 2 , the present embodiment provides a method for manufacturing a heat storage electric heating device using power frequency induction heating, the method comprising:

[0046] First of all, according to the characteristics of heat demand for household heating, the availability of using power frequency current to realize electricity-to-heat conversion is investigated. In normal use, the thermal storage electric heater chooses to heat during the valley electricity period at night, and the heating time is 8 hours, and the other 16 hours in a day are pure heat release time. For simplification, within 24 hours a day, the heater releases heat evenly, with a rated power of 1.6kW (the general heating area is 10-15m 2 ) electric heater as an example, the total heat required is Q=16×60×60×1600=92160kJ. Under the excitation of alternating current (frequency f), the unit length cylindrical metal rod (radius r 0 ) The average heating power of the metal is (neglec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com