A food heating production line with microwave suppression function

A microwave suppression and microwave heating technology, which is applied in lighting and heating equipment, heating to dry solid materials, food science, etc., can solve the problems of difficult manufacturing and processing of water-loaded equipment, poor anti-leakage ability, and large floor space. Achieve the effect of improving the microwave suppression effect, strengthening the anti-leakage ability, and improving the effect of energy saving and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

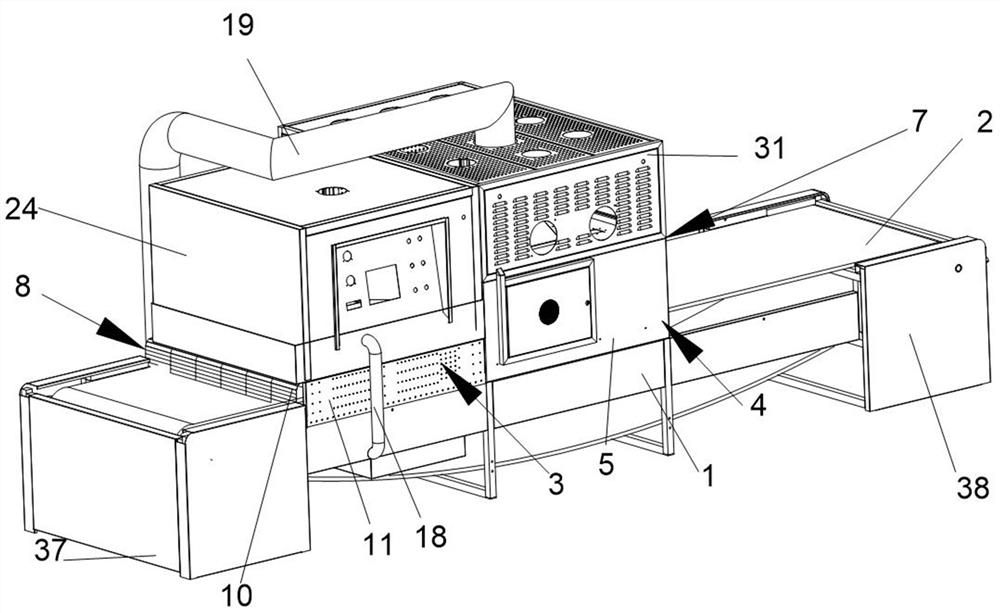

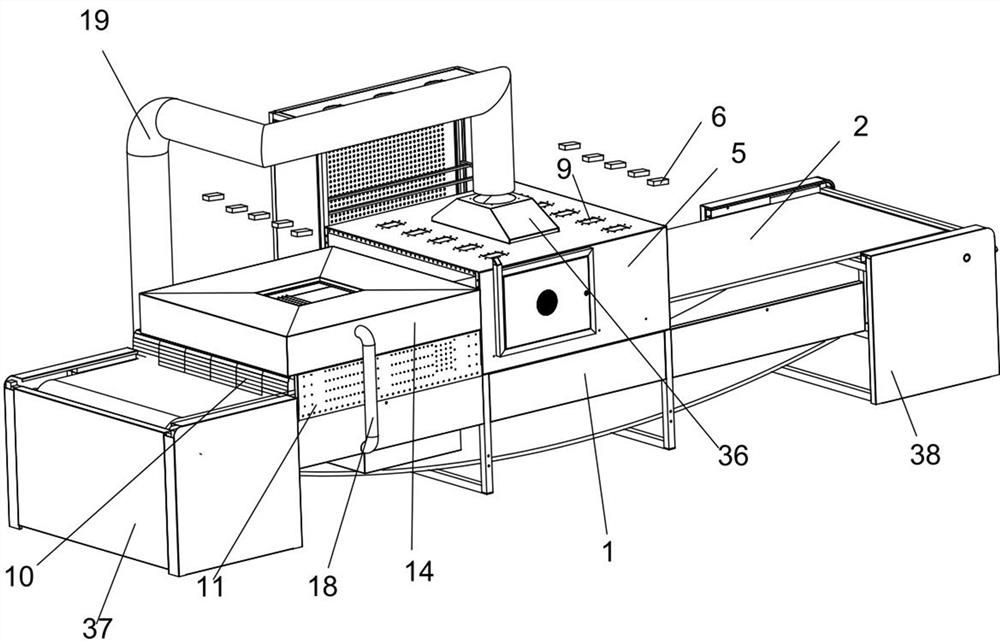

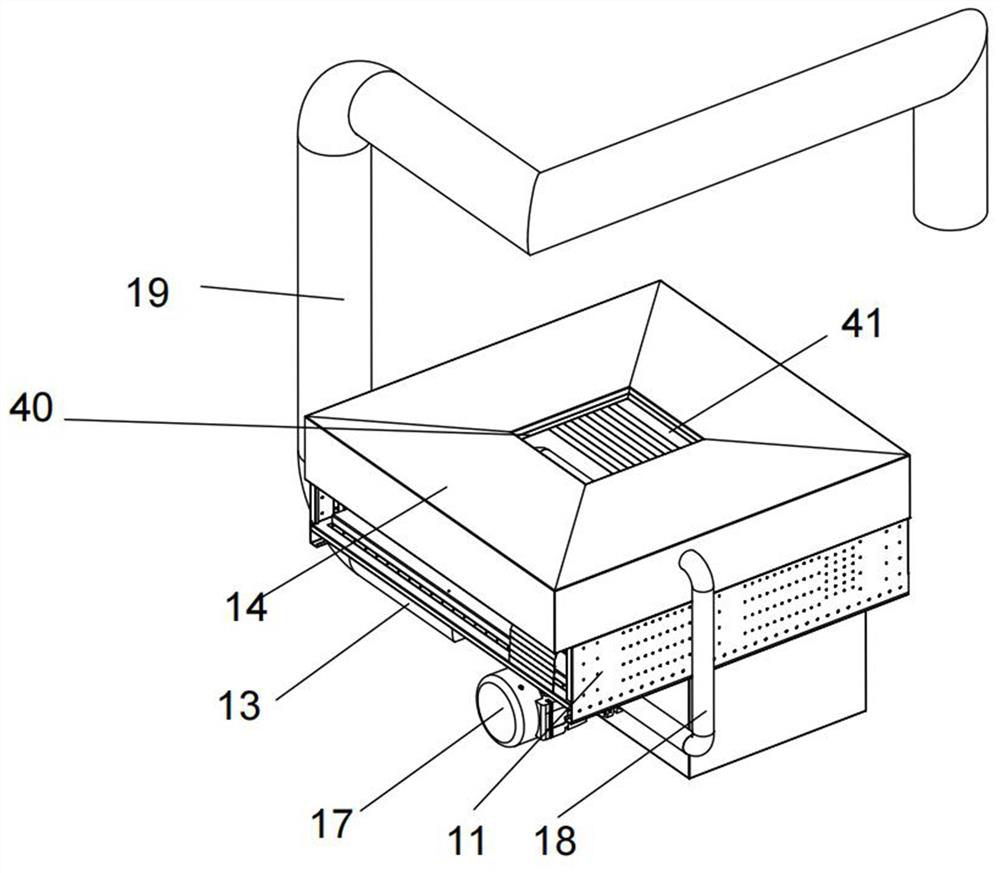

[0034] like Figure 1-13As shown in the figure, a food heating production line with microwave suppression function provided by the present invention includes a transmission rack 1, and a transmission device 2, a microwave suppression section 3 and a tunnel microwave heating section 4 are arranged on the transmission rack 1. The conveying device 2 runs through the microwave suppression section 3 and the tunnel microwave heating section 4 respectively according to the conveying direction. The entrance 8 is provided with more than one microwave door curtain 10 that closes the entrance. The tunnel microwave heating section 4 includes a microwave heating chamber 5 and more than one microwave generator 6. One side of the microwave heating chamber 5 is connected to the microwave suppression section 3. The microwave heating chamber 5 is provided with more than one microwave heating through-hole 9, and each microwave heating through-hole 9 is provided with a microwave generator 6; the ...

Embodiment 2

[0046] like Figure 14 As shown, the present invention provides a food heating production line with microwave suppression function. In order to further improve the suppression effect, more than one tunnel microwave heating section 4 is provided on the conveying device 2, and each tunnel microwave heating section 4 is provided. A microwave suppressing section 3 is provided on both sides of the heater, and the suction pipes 19 on the two microwave suppressing sections 3 matched with the same tunnel microwave heating section 4 are connected to the corresponding tunnel microwave through a connecting tube 42. The heating section 4 is connected, and the microwave suppression section 3 is arranged on both sides of the tunnel microwave heating section 4 to further improve the suppression effect on microwaves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com