Product quality real-time card control method and system

A product quality and product technology, applied in the field of real-time card control of product quality, can solve problems such as inability to real-time data, non-sharing of information between rapid rail transit product departments, etc., to achieve the effect of improving disposal efficiency, rapid and intelligent verification, and reducing recurrence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, an example is used for illustration, but it does not mean that the system or method provided by the present invention can only be applied to railway products. It can also be applied to the card control of other products according to specific scenarios or different verification objects.

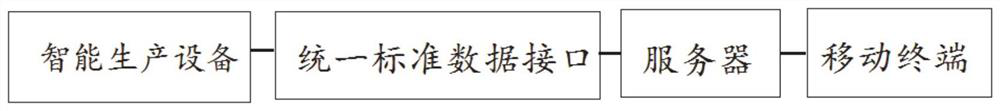

[0038] Specifically, see the attached figure 1 As shown, a real-time card control system for product quality includes: intelligent production equipment, unified standard data interface, server, and mobile terminal;

[0039] Intelligent production equipment, using intelligent production equipment for construction and repair operations, intelligent equipment records production process data in real time, including product data and production data; among them, product data is data such as specifications, and production data is data such as voltage and current;

[0040] Unified standard data interface, all production data generated by intelligent production equipment is ...

Embodiment 2

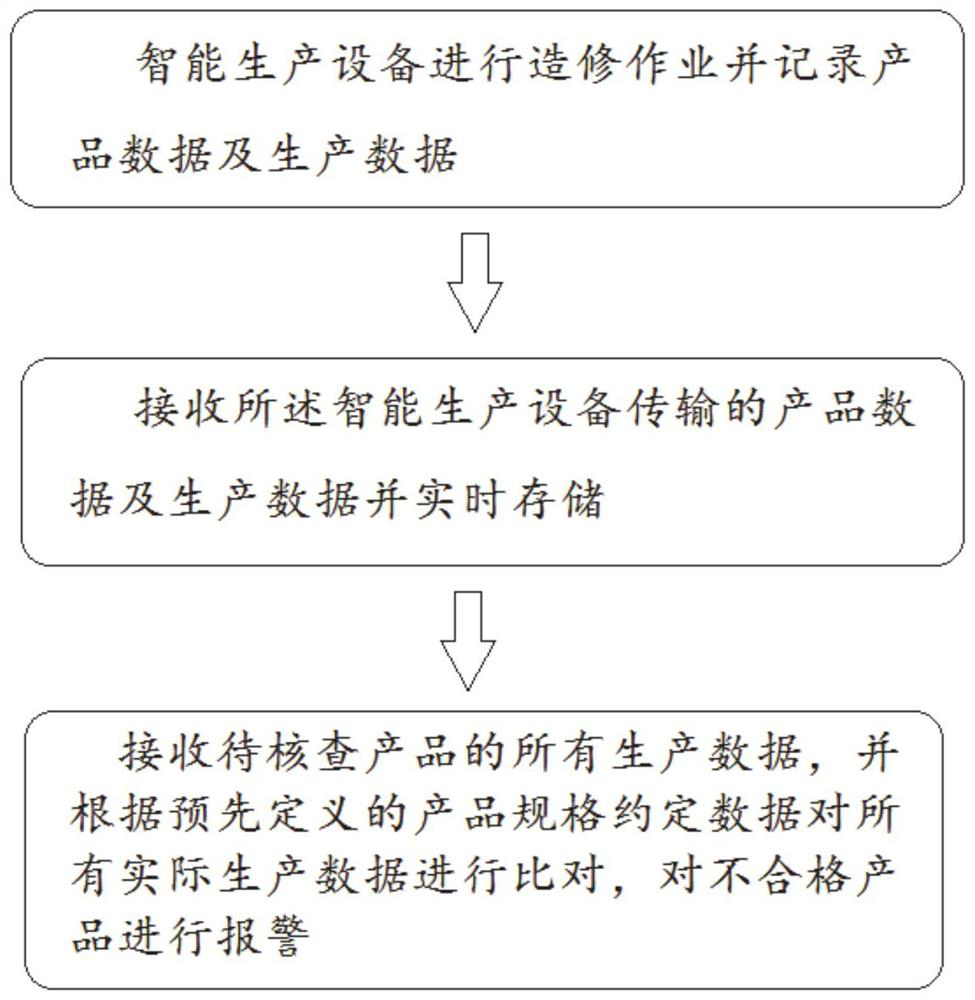

[0052] Based on the system of Embodiment 1, a real-time card control method for product quality is disclosed, see attached figure 2 shown, including:

[0053] Intelligent production equipment performs repair operations and records product data and production data;

[0054] Receive product data and production data transmitted by the intelligent production equipment and store them in real time;

[0055] Receive all the production data of the products to be checked, and compare all the actual production data according to the pre-defined product specification agreement data, and give an alarm to unqualified products.

[0056] Specifically, it also includes a searching step. Before the mobile terminal receives all the production data of the product to be checked, according to the received search keyword, associate the keyword with all the production data of the product to be checked and output.

[0057] The intelligent detection of manufacturing supervision of the disclosed tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com