Driving mechanism and pump using same

A driving mechanism and pump plate technology, applied in the direction of rotary piston type/swing piston type pump components, machines/engines, liquid fuel engines, etc., can solve the problem of uneven motor, equipment stability and noise influence, uneven motor rotation and other problems to achieve the effect of reducing pressure fluctuation and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

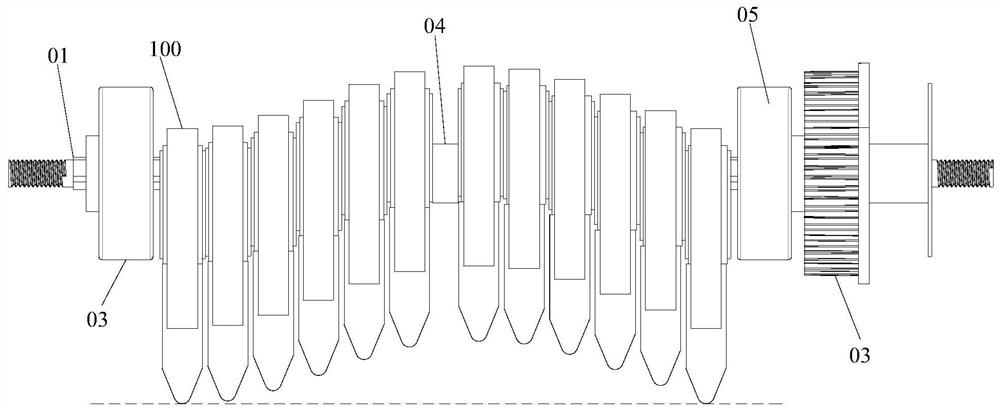

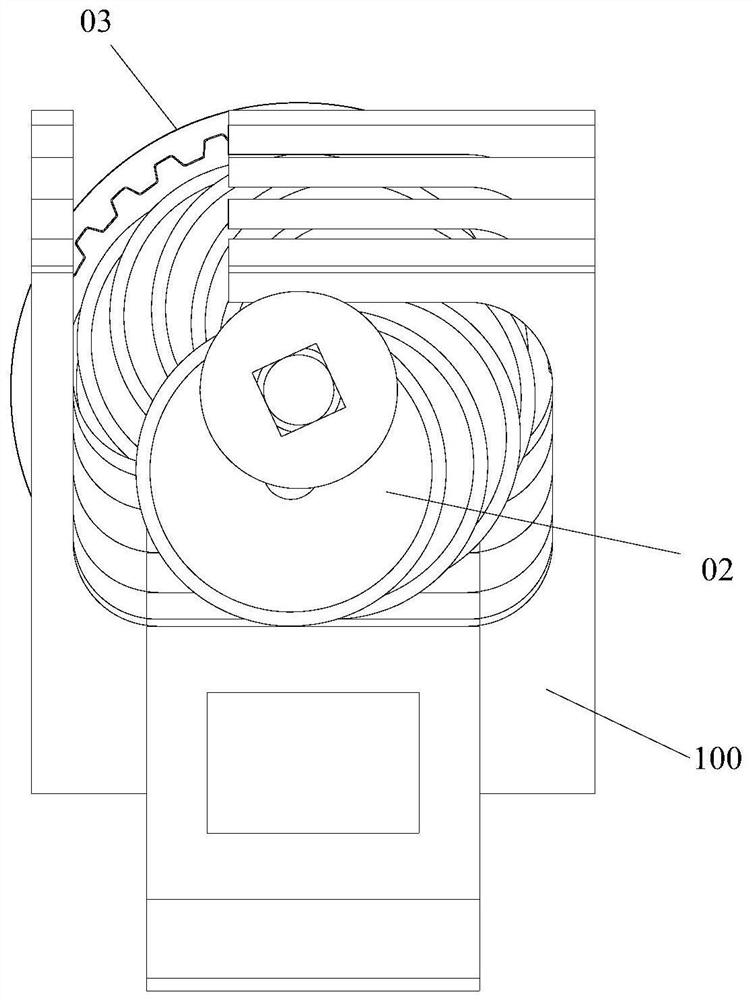

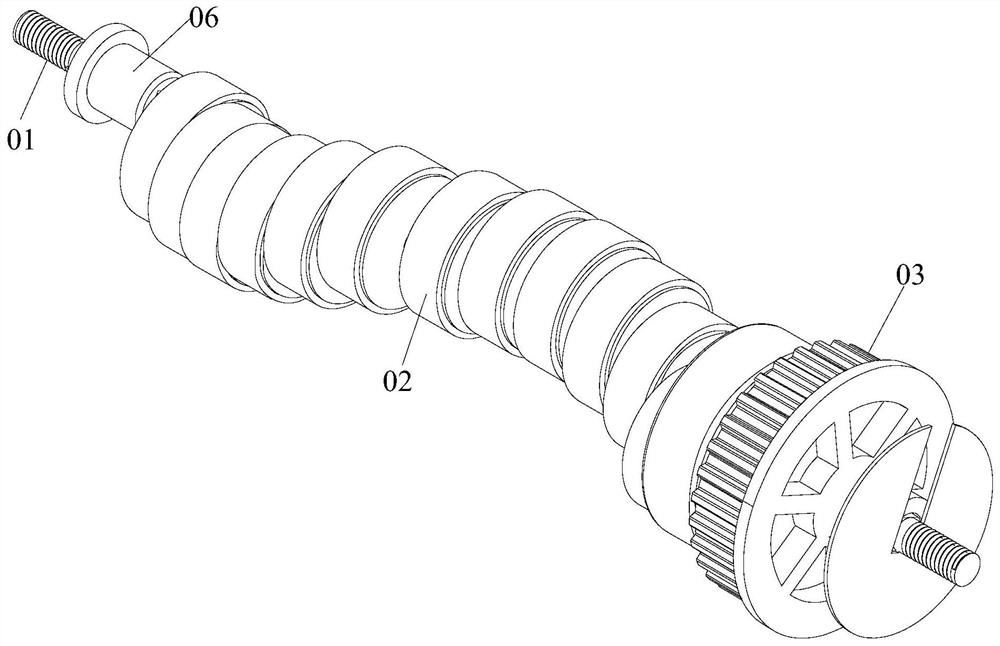

[0054] Such as Figure 1 to Figure 4 As shown, the present invention provides a driving mechanism, including a camshaft 01 rotatably arranged on the pump housing 07, several cams 02 are arranged on the camshaft 01, a pump blade 100 is arranged on the cam shaft 02, and a pump blade 100 is provided on the pump blade 100. There are cam grooves 3, and the cams 02 are pressed against the cam grooves 3; these cams 02 are of cylindrical structure and are arranged eccentrically on the camshaft 01, and there is a misalignment angle between two adjacent cams 02, so that there is always only one pump The sheet 100 is able to compress the tubing.

[0055] Among them, such as figure 1 As shown, the camshaft 01 is installed on the pump casing 07 through the bearing 05. Considering that the camshaft 01 is a square shaft, a sleeve 06 can be sleeved on the camshaft 01 for installing the bearing 05. On the camshaft 01 A transmission wheel 03 is also arranged on the top, which is used to drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com