Shaft body cooling and heat dissipation device for CNC machine tool processing

A heat dissipation device and technology of CNC machine tools, which are applied in the direction of metal processing equipment, metal processing machinery parts, milling machine equipment, etc., can solve the problems of internal parts that are easy to burn, do not comply with energy saving and emission reduction, and affect the accuracy of milling cutters. Convenience, improved convenience, less usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

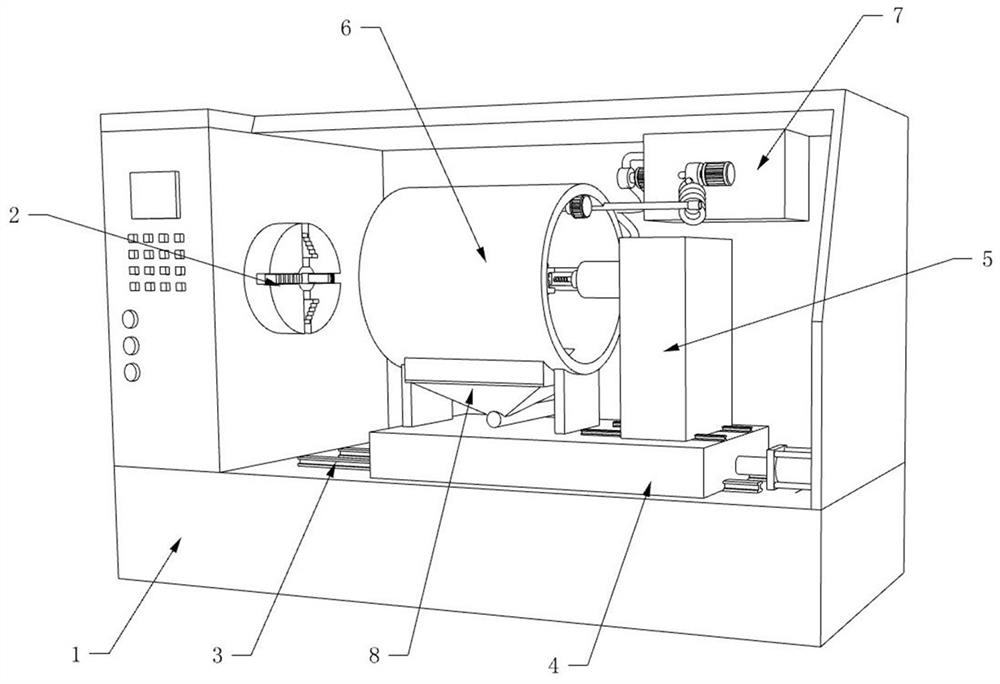

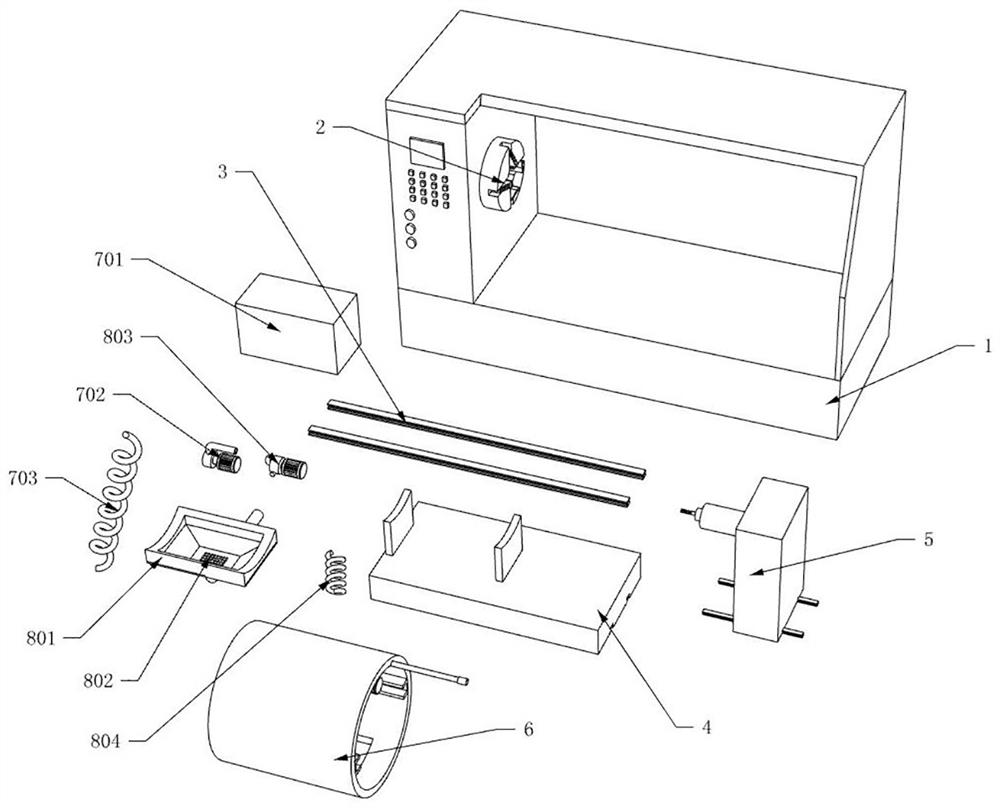

[0032] Reference Figure 1-2, the present embodiment relates to a CNC machine tool processing with shaft body cooling heat dissipation device, including the machine tool body 1, the machine tool body 1 is provided with a machining area, one end of the machining area is installed with a fixture 2, the other end is installed with a movable CNC milling cutter mechanism, CNC milling cutter mechanism is installed on the double guide rail 3 at the bottom of the machining area through the drive mechanism, CNC milling cutter mechanism comprising a moving base 4, milling cutter body 5, cooling heat dissipation mechanism 6, mobile base 4 through the cylinder drive, milling cutter body 5 and cooling heat dissipation mechanism are installed on the mobile base 4, Cooling heat dissipation mechanism is a transparent structure at both ends and located between the fixture 2 and the milling cutter body 5, the milling head of the milling cutter body 5 extends to the cooling cooling mechanism to proce...

Embodiment 2

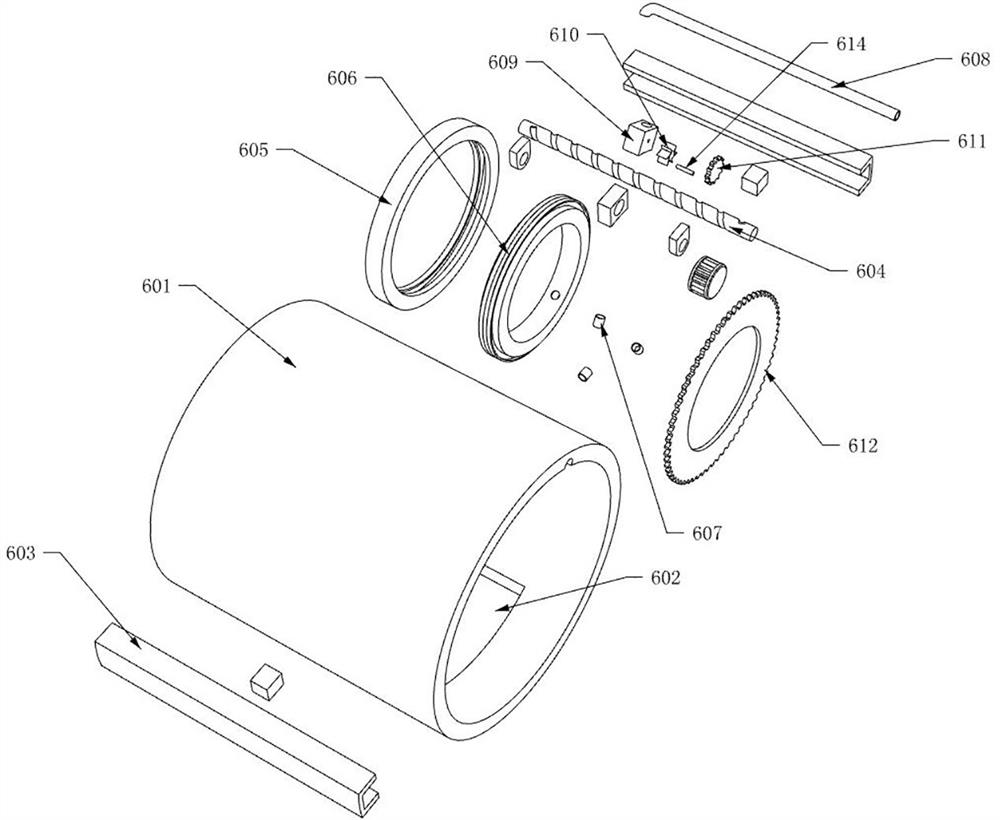

[0038] Reference Figure 3-6 , the present embodiment and the embodiment of a difference is that the structure of the cooling ring body is different, in the present embodiment, the cooling ring body includes the outer ring body 605 and the inner ring body 606, the inner ring body 606 rotation is installed on the inner ring wall of the outer ring body 605, the outer ring body 605 and the inner ring body 606 are hollow structures, and the hollow cavity of the two is interconnected to form a circular reservoir 613, the outer wall of the inner ring body 606 is fixed with a ring gear 612, and the drive mechanism is installed on the outer ring body 605, The drive mechanism is connected to the ring gear 612 transmission and drives the inner ring body 606 rotation, the drive mechanism is connected with the annular reservoir 613 and the metal tube 608.

[0039] The drive mechanism comprises housing 609, drive impeller 610, drive shaft 614 and drive gear 611, housing 609 is fixed mounted on th...

Embodiment 3

[0042] Reference Figure 7, the present embodiment and Example I and Example TWO are different in that the coolant circulation mechanism 8 is added to achieve the reuse of coolant, in the present embodiment, the bottom of the cooling and dissipation mechanism 6 is provided with a coolant circulation mechanism 8, the coolant circulation mechanism 8 comprises a collection tank 801, a filter core 802, a metal tube two 805, a spring hose two 804 and a return pump 803, a protective cover 601 is located at the bottom of the collection tank with an installation slot 602, the collection tank 801 is installed at the installation slot 602, The middle of the collection tank 801 is detachablely installed with a filter core 802, and the bottom of the collection tank 801 is connected to one end of the metal tube II 805, the other end of the metal tube II 805 is connected to the spring hose II 804, the spring hose II 804 is connected to the coolant tank 701 by the return pump 803.

[0043] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com