Transverse transferring mechanism and working method

A transfer and lateral technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of cargo retention and easy deviation of cargo, so as to reduce the failure rate, reduce the installation complexity, and simplify the mechanical structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments.

[0029] In this embodiment, the following technical solutions are adopted:

[0030] 1. The direction of the main conveying line adopts the multi-ribbed belt roller transmission method.

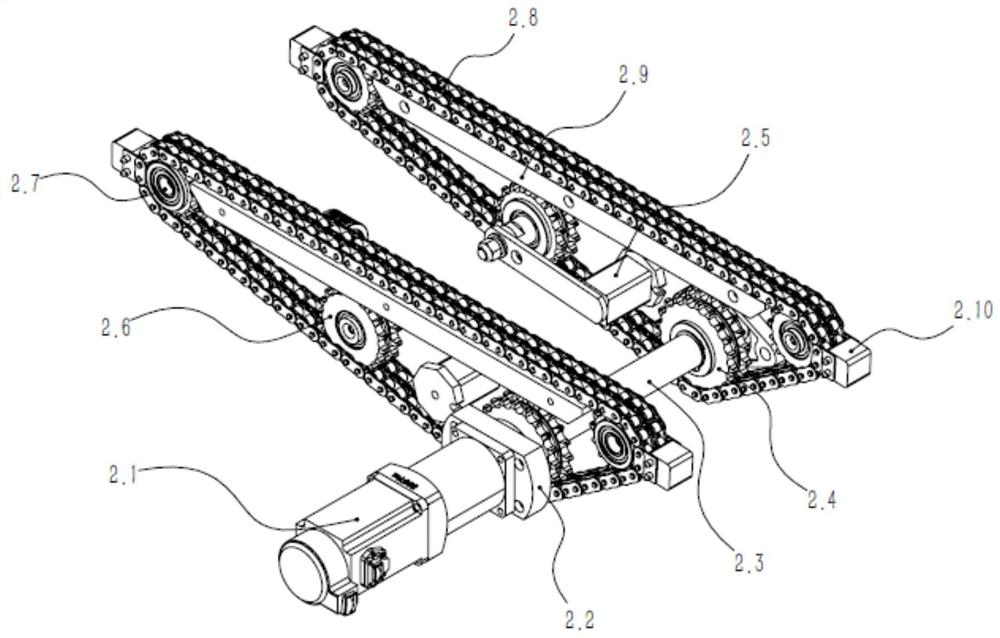

[0031] 2. The lateral transfer adopts the servo motor to drive the transfer chain, which drives the transfer block to transfer the goods or the turnover box to the conveying auxiliary line for transmission.

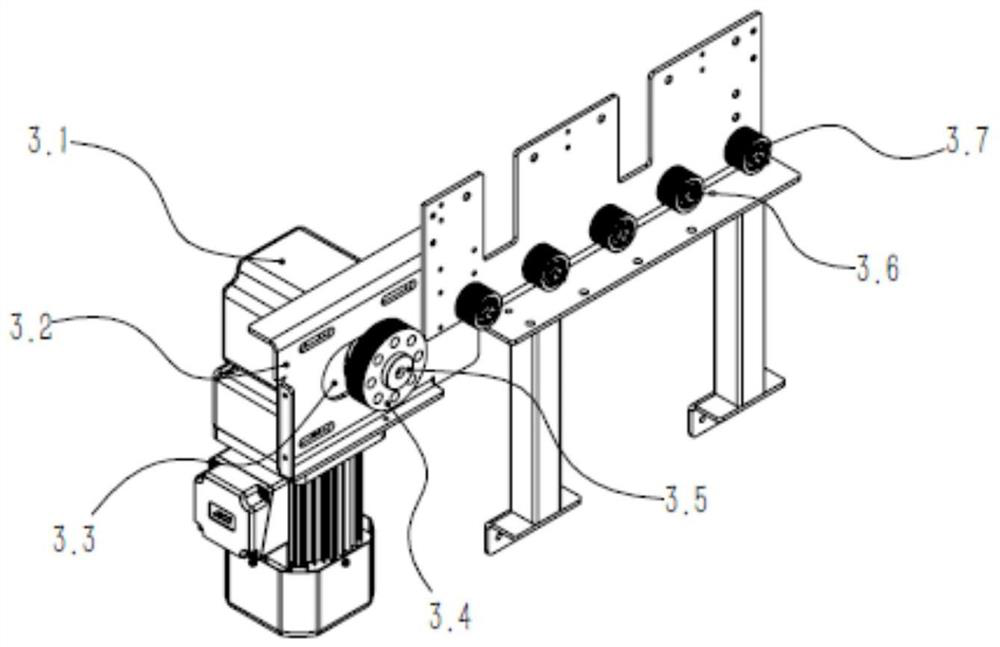

[0032] 3. The goods or turnover boxes are controlled by photoelectricity to control the rise and fall of the blocking mechanism, so that the goods or turnover boxes are waiting for transfer or release at the transfer place.

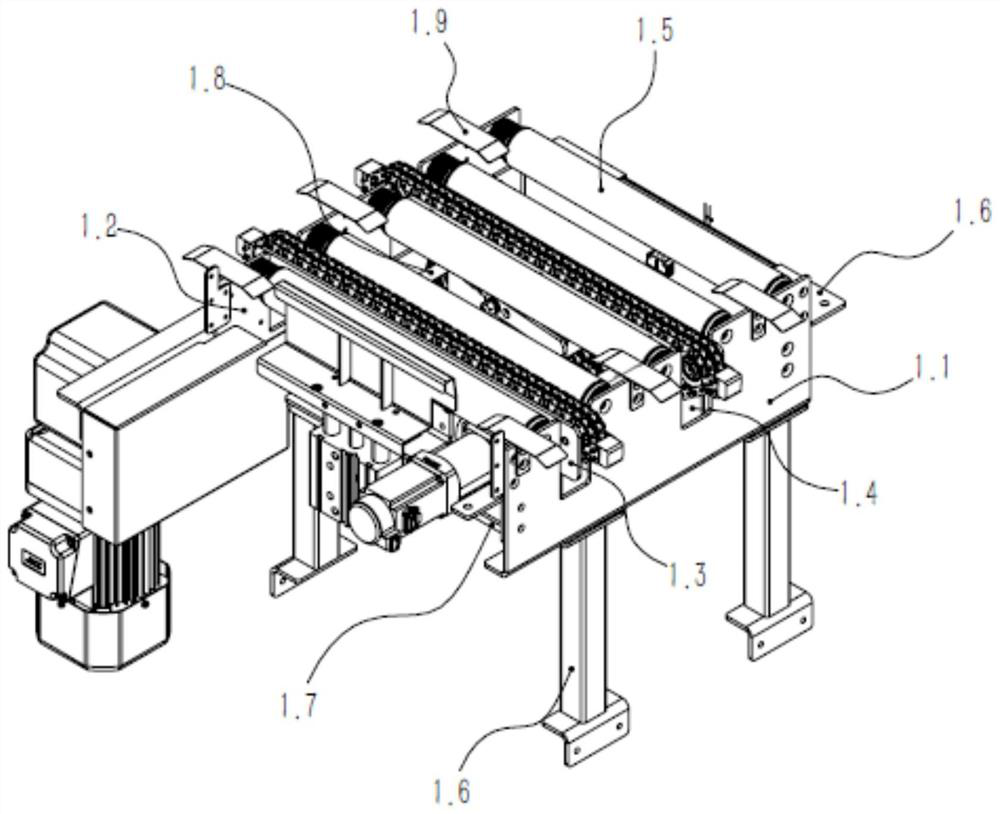

[0033] Lateral transfer mechanism, see figure 1 , including the roller left side plate 1.1, the roller right side plate 1.2, the roller left side plate 1.1 and the roller right side plate 1.2 are respectively mounted on the transfer base plate 1.7. The upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com