Coating base material for large-scale preparation of graphene oxide film and prepared graphene oxide film

A technology for large-scale preparation and coating of substrates, applied in the fields of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., which can solve the problem that the appearance of graphene oxide film is bulging, the coating substrate cannot be reused, and the surface uniformity is poor. problems, to achieve the effect of improving the appearance of damage, improving the appearance of bubbling, and enhancing the effect of re-wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

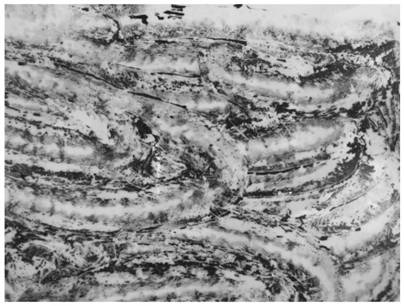

[0111] The preparation method of graphene oxide film is as follows:

[0112] 1) Graphene oxide slurry with a solid content of 8%, a viscosity of 20000mPa·s, and an average graphene oxide sheet diameter of 2 μm is coated on the coated substrate with a thickness of 1.5mm;

[0113] 2) The material of the coating substrate is polypropylene, the weaving method is twill, the yarn structure is monofilament, the thickness of polypropylene is 500 μm, the warp density is 200 threads / inch, the weft density is 100 threads / inch, and the air permeability is 100L / m 2 / s, the tensile strength is 2000N, and the surface tension is 100mN / m;

[0114] 3) The coated slurry moves together with the coated substrate, and is dried by the oven of the coating machine, the drying temperature is 100°C, the wind speed is 20m / s, and the drying speed is 3m / min;

[0115] 4) Wet the dried graphene oxide film, and the wet method is to spray water mist on both sides, that is, spray water mist from the side of th...

Embodiment 2

[0124] The preparation method of graphene oxide film is as follows:

[0125] 1) Graphene oxide slurry with a solid content of 5%, a viscosity of 10000 mPa·s, and an average graphene oxide sheet diameter of 3 μm is coated on the coated substrate with a thickness of 2.5 mm;

[0126] 2) The material of the coating substrate is nylon, the weaving method is plain weave, the yarn structure is multifilament, the thickness of nylon is 500 μm, the warp density is 120 threads / inch, the weft density is 80 threads / inch, and the air permeability is 60L / m 2 / s, the tensile strength is 2500N, and the surface tension is 60mN / m;

[0127] 3) The coated slurry moves together with the coated substrate, and is dried by the oven of the coating machine, the drying temperature is 80°C, the wind speed is 12m / s, and the drying speed is 1.2m / min;

[0128] 4) Wet the dried graphene oxide film, and the wet method is to spray water mist on both sides, that is, spray water mist from the side of the graphene ...

Embodiment 3

[0133] The preparation method of graphene oxide film is as follows:

[0134] 1) The graphene oxide slurry with a solid content of 10%, a viscosity of 45000mPa·s, and an average graphene oxide sheet diameter of 2 μm is coated on the coated substrate with a thickness of 0.75mm;

[0135] 2) The material of the coating substrate is polyester, the weaving method is forged, the yarn structure is monofilament, the thickness of polyester is 500 μm, the warp density is 300 threads / inch, the weft density is 150 threads / inch, and the air permeability is 120L / m 2 / s, the tensile strength is 3000N, and the surface tension is 130mN / m;

[0136] 3) The coated slurry moves together with the coated substrate, and is dried by the oven of the coating machine, the drying temperature is 120°C, the wind speed is 30m / s, and the drying speed is 8m / min;

[0137] 4) Wet the dried graphene oxide film, and the wet method is to spray water mist on both sides, that is, spray water mist from the side of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com