Method for acclimating activated sludge by using glucose as co-substrate and application of acclimatedactivated sludge in deep treatment of coking wastewater

A technology of coking wastewater and activated sludge, which is applied in water/sludge/sewage treatment, special compound water treatment, biological water/sewage treatment, etc. and degradation efficiency, saving operating costs and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

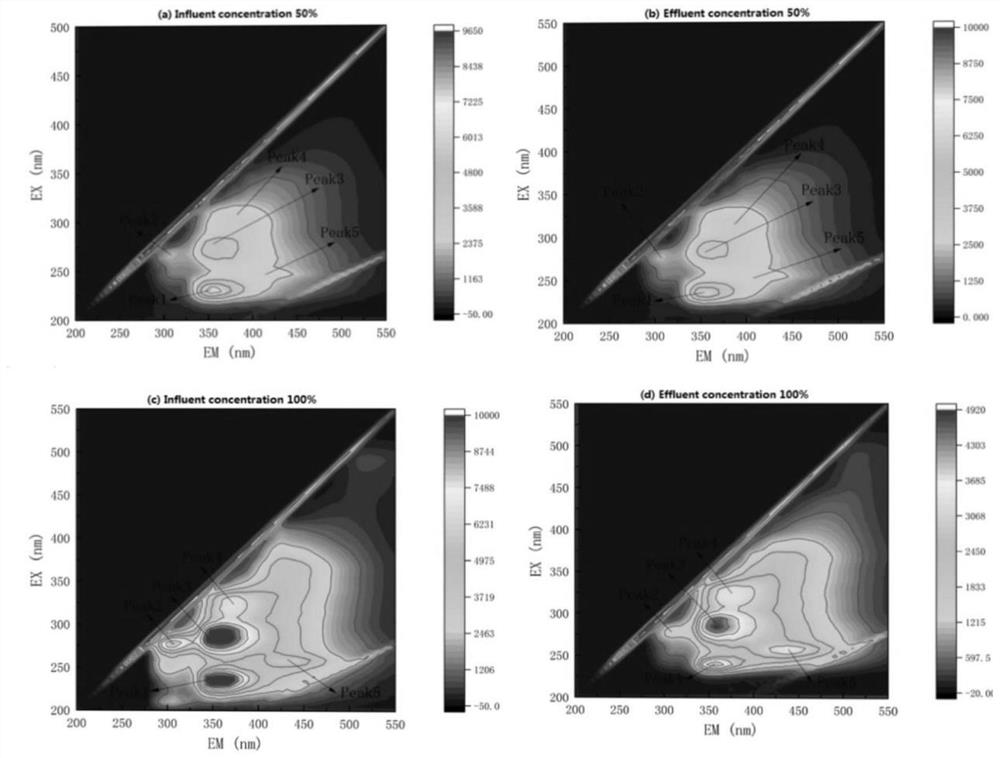

Image

Examples

Embodiment 1

[0026] In this example, the effective volume of the SBR is 3L, the COD of the influent into the reactor is about 210mg / L, the ammonia nitrogen in the influent is 4.3mg / L, the temperature is 20.1-21.5°C, the MLSS is 3500±150mg / L, and the pH is 8.45 ~8.86, DO is 3.0±0.5mg / L.

[0027] In this embodiment, the domestication process of the activated sludge in the SBR system is as follows:

[0028] 1) The amount of sludge inoculum is 4500mg / L. Add 10% concentration of coking wastewater into the SBR, and replace the remaining volume with deionized water to make the effective volume of the reactor reach 3L.

[0029] 2) Turn on the rotameter, aerate the SBR, and maintain the dissolved oxygen of the mixed solution in the pool at 2.5-3.5mg / L, the temperature at 21.3-22.6°C, and the pH at 8.45-8.86.

[0030] 3) Turn on the coking wastewater inlet pump, the initial coking wastewater inlet volume is 300mL, and the remaining volume is replenished with deionized water.

[0031] 4) According ...

Embodiment 2

[0041] In this implementation case, the effective volume of the SBR is 3L, the COD of the influent into the reactor is 254mg / L, the ammonia nitrogen in the influent is 4.5mg / L, the temperature is 20.9~22.5℃, the MLSS is 6500±150mg / L, and the pH is 8.64~ 8.79, DO is 3.0±0.5mg / L.

[0042] 1) The amount of sludge inoculum MLSS is 6000mg / L, and the effluent from the secondary sedimentation tank after the anoxic-aerobic biological treatment of the coking wastewater treatment plant is added to the SBR to make the effective volume of the reactor reach 2.5L.

[0043] 2) Turn on the rotameter, aerate the SBR, maintain the dissolved oxygen of the mixed solution in the pool at 2.5-3.5mg / L, the temperature at 20.9-22.5°C, and the pH at 8.64-8.79.

[0044] 3) Turn on the coking wastewater inlet pump, and feed the reactor with an effective volume of 2.5 L at a flow rate of 300 mL / min.

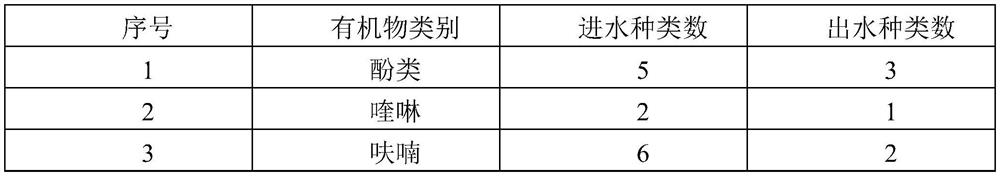

[0045] 4) With glucose concentrations of 200mg / L and 400mg / L as the standard, record them as the low-car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com