Advanced bio-treatment technology for waste water

A technology of advanced treatment and biological treatment, applied in anaerobic digestion treatment and other directions, can solve the problems of increasing equipment complexity and practical operation difficulty, failing to completely solve the problems of microbial adhesion and deposition, iron filing bed hardening and passivation, etc., to achieve water treatment. The cost increase is limited, the operation is easy to control, and the consumption is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

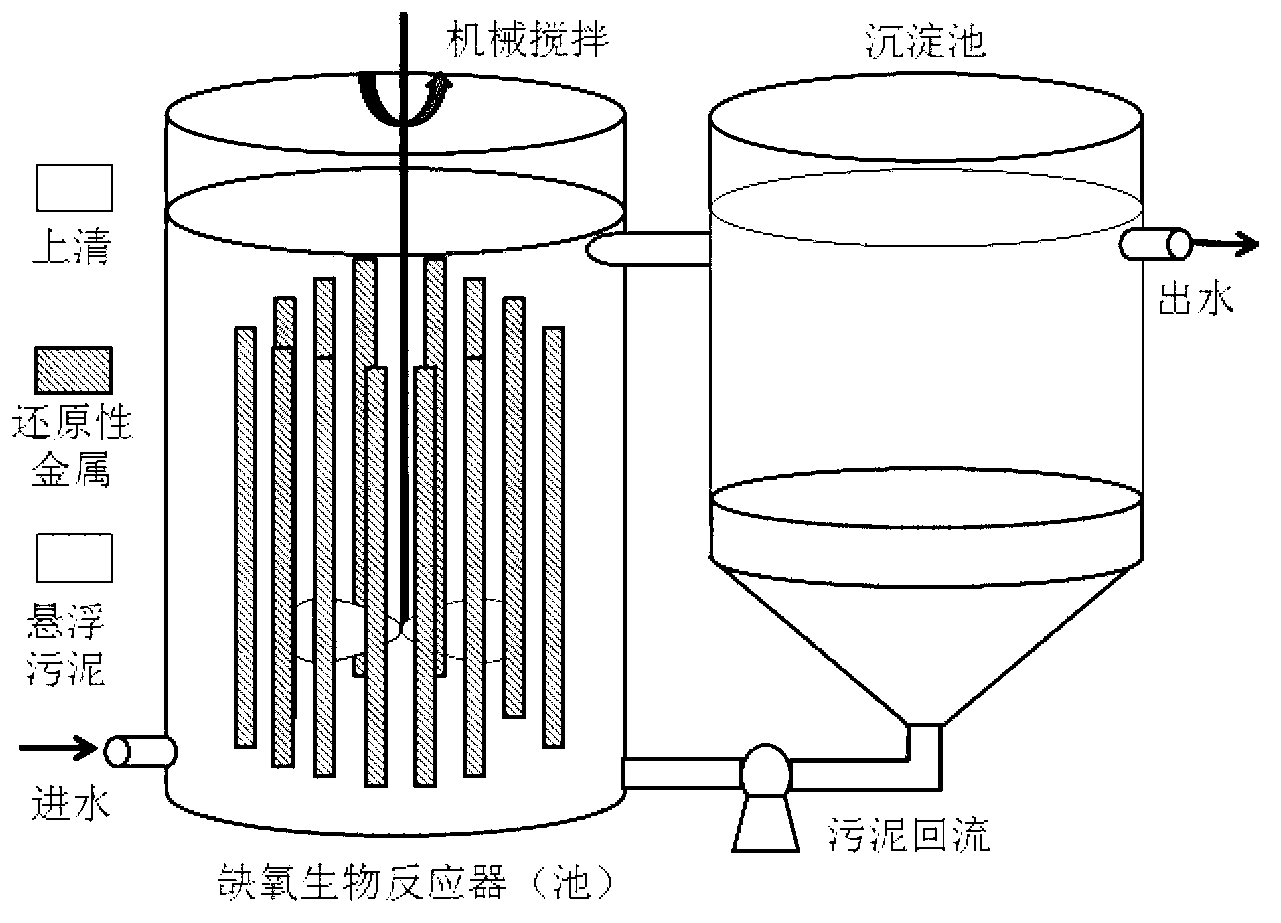

Image

Examples

Embodiment 1

[0021] According to the method of the present invention, a set of waste water biological advanced treatment device is formed, the effective volume of the treatment device is 25L, the carbon steel bars through alkali cleaning and pickling are placed around the stirring paddle of the treatment device, and the residence time is about 6h under the running state. The device adopts the middle mechanical Stirring mode, the stirring speed gradient is 20s -1 , the temperature of the wastewater in the reaction device is 28-33°C, the pH value is 6.0-7.2, and the oxidation-reduction potential is about -100mV. A conventional contact oxidation tank is installed behind the wastewater biological advanced treatment device, and the residence time of the contact oxidation tank is about 10 hours. The treatment object of the combined device is the effluent of propylene oxide wastewater after secondary primary sedimentation + activated sludge + contact oxidation process, which uses potassium dich...

Embodiment 2

[0024] Form a set of wastewater biological advanced treatment device according to the method of the present invention, the effective volume of the treatment device is 50L, the stirring paddle of the treatment device is placed around the common pig iron sheet, and the residence time is about 8h under the running state. The device adopts the middle mechanical stirring mode, and the stirring speed gradient is: 70s -1 In the running state, the temperature of the wastewater in the reaction vessel is 25°C, the pH is 7.0-9.0, and the oxidation-reduction potential is about -300mV. A conventional activated sludge biological treatment tank is placed after the low redox potential anoxic biological treatment device, and the residence time of the activated sludge tank is 8 hours. The treatment object of the combined device is the effluent of industrial wastewater treated by activated sludge process in a chemical industry park. It uses potassium dichromate as the oxidant to measure the ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com