Efficient method for treating chemical wastewater

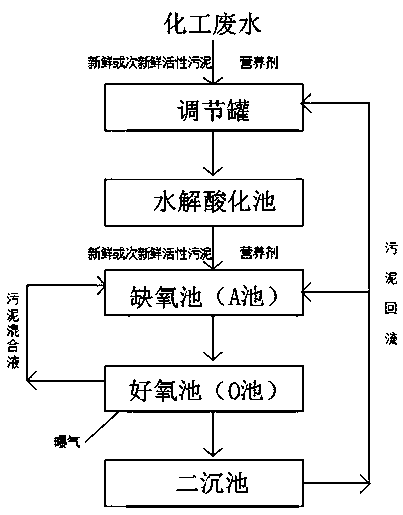

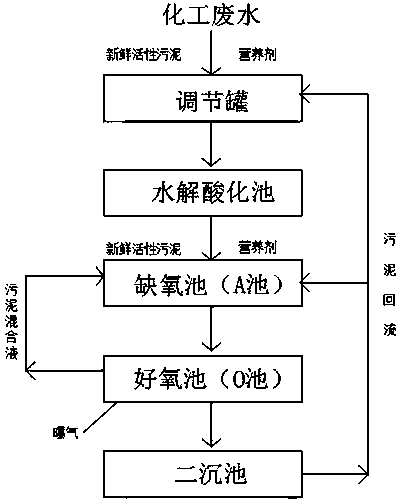

A high-efficiency technology for chemical wastewater, applied in the field of water treatment, can solve the problems of insufficient nutrients, poor biochemical properties, and imbalanced ratios, and achieve the effects of improving biochemical anaerobic processes, improving degradation efficiency, and improving B/C ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: as figure 2 As shown, fresh activated sludge is added to the 25,000 t / d sewage treatment plant, which can be transported through pipelines through the adjacent upstream wastewater treatment station, and its water content is 98.5%.

[0040] S1: Cultivate and domesticate a sufficient number of bacterial populations or sludge;

[0041] S2: Inoculate activated sludge into the anoxic tank, continuously add 550t / d of fresh activated sludge to a total of 3200t, and add nutrients as needed, target concentration of AO system sludge inoculation: 2000mg / L;

[0042] S3: Start the mixer of the anoxic tank system, and intermittently turn on the internal return pump to make the sludge mixture in the anoxic tank and the aerobic tank circulate properly;

[0043] S4: Intermittently turn on the blower of the aerobic pool system to control DO. Among them, the DO in the anoxic pool is ≤0.48 mg / L, and the DO in the aerobic pool is 2.2 mg / L. Filler is added in batches in the me...

Embodiment 2

[0047] Embodiment 2: as figure 2 As shown, fresh activated sludge is added to the 25,000 t / d sewage treatment plant, which can be transported through pipelines through the adjacent upstream wastewater treatment station, and its water content is 98.5%.

[0048] S1: Cultivate and domesticate a sufficient number of bacterial populations or sludge;

[0049] S2: Inoculate activated sludge into the anoxic tank, continuously add 450t / d of fresh activated sludge to a total of 2800t, and add nutrients as needed, target concentration of AO system sludge inoculation: 1000mg / L;

[0050] S3: Start the mixer of the anoxic tank system, and intermittently turn on the internal return pump to make the sludge mixture in the anoxic tank and the aerobic tank circulate properly;

[0051] S4: Intermittently turn on the blower of the aerobic pool system to control DO. Among them, the DO in the anoxic pool is ≤0.48 mg / L, and the DO in the aerobic pool is 1.8 mg / L. Filler is added in batches in the ...

Embodiment 3

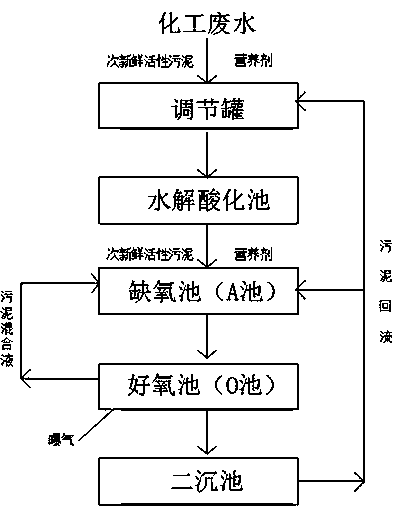

[0056] Embodiment 3: as image 3 As shown, for the 25,000 t / d sewage treatment plant, add sub-fresh activated sludge, which is transported from other places by vehicles, and the moisture content of the sub-fresh activated sludge is 85%.

[0057] S1: Cultivate and domesticate a sufficient number of bacterial populations or sludge;

[0058] S2: Inoculate activated sludge into the anoxic tank, continuously add 45 t / d sub-fresh activated sludge for a total of 280t, supplemented by adding nutrients according to the situation, AO system sludge inoculation target concentration: 1000 mg / L ;

[0059] S3: Start the mixer of the anoxic tank system, and intermittently turn on the internal return pump to make the sludge mixture in the anoxic tank and the aerobic tank circulate properly;

[0060] S4: Intermittently turn on the blower of the aerobic pool system to control DO. Among them, the DO in the anoxic pool is ≤0.48 mg / L, and the DO in the aerobic pool is 1.8 mg / L. Filler is added i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com