Denitrification filter tank

A denitrification filter and backwashing technology, which is applied in the field of denitrification filter, can solve the problems of low biofilm concentration in the filter layer, low denitrification load, and high investment in active sand filter, so as to simplify management complexity and reduce Operating cost, effect of improving effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples, but the following examples do not limit the present invention in any way.

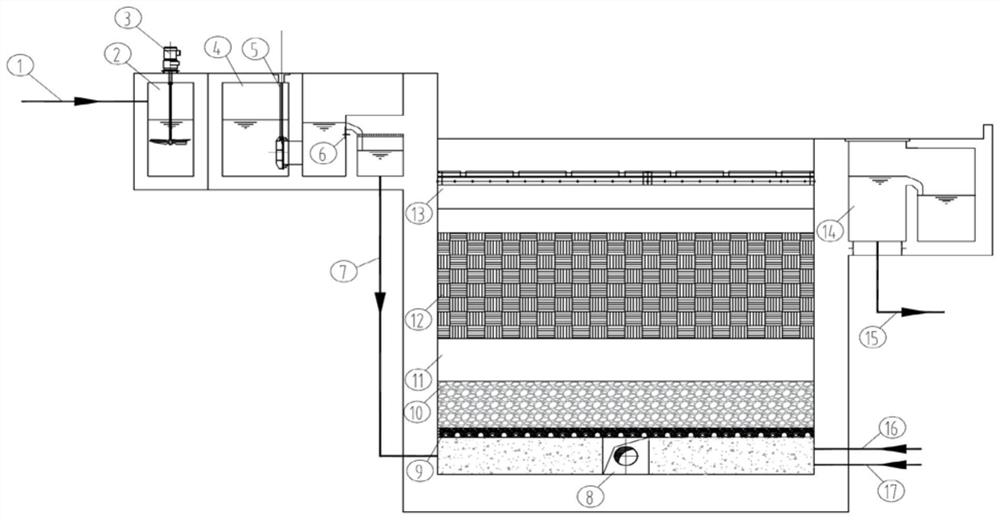

[0019] Such as figure 1 As shown, the denitrification filter provided by the present invention includes: a denitrification filter body, an inlet pipe 1, a mixing tank 2, a water distribution channel 4, a water distribution weir 6, an outlet channel 14, a backwash blower 16 and a backwash water pump 17;

[0020] Among them, one end of the water inlet pipe 1 is connected to the input water source, and the other end is connected to the mixing tank 2; a carbon source dosing system 3 is provided in the mixing tank 2, and the mixing tank 2 is connected to the distribution channel 4, and a gate 5 is provided in the distribution channel 4 , the water distribution channel 4 communicates with the water distribution weir 6, the inner wall of the water distribution weir 6 is provided with a polyurethane soft filler ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com