Kitchen waste wastewater treatment system and treatment process thereof

A wastewater treatment system and kitchen waste technology, applied in water/sewage treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve the problems of complex odor treatment process and uncontrollable kitchen waste wastewater , to achieve the effect of improving dehydration efficiency, facilitating dehydration separation, and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

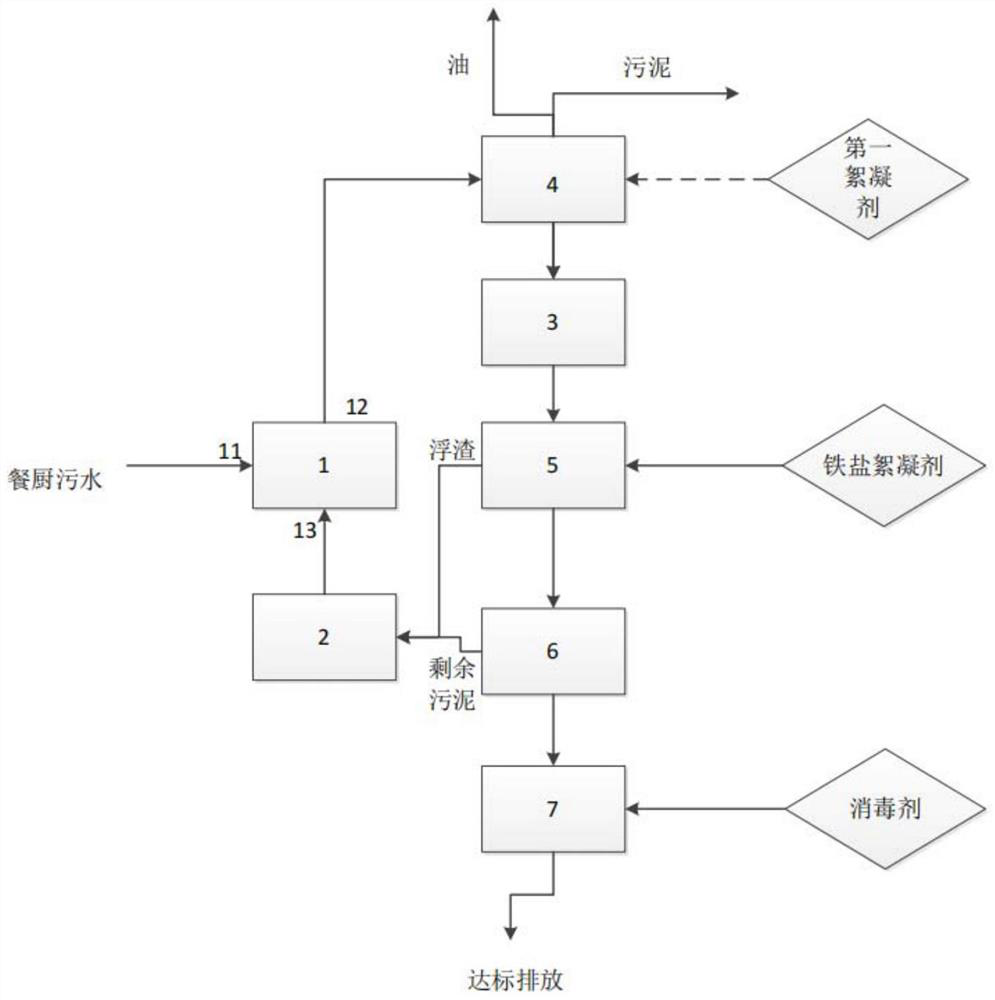

[0052] This embodiment provides a kind of food waste wastewater treatment system, such as figure 1 As shown, it includes a slurry tank 1, a three-phase separation unit 4, a regulating tank 3, an air flotation tank 5 and a biochemical tank 6 which are connected in sequence.

[0053] The slurry tank is provided with a water inlet 11 , a water outlet 12 and a sludge inlet 13 . The water inlet 11 is to allow the kitchen waste wastewater to be treated to enter the slurry tank, the water outlet 12 is to discharge the kitchen waste wastewater mixed with the activated sludge into the three-phase separation unit 4, and the sludge inlet 13 It is to discharge the activated sludge in the scraping tank 1 into the slurry tank 1. In the slurry tank 1, the kitchen garbage wastewater is fully mixed with the activated sludge, which can remove the odor in the kitchen garbage wastewater and absorb the oil phase in the wastewater.

[0054] The three-phase separation unit 4 can be one of a three-...

Embodiment 2

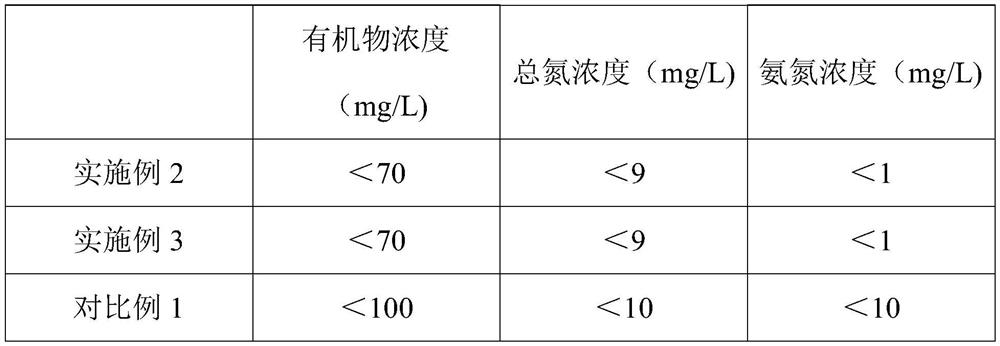

[0061] This embodiment provides a process for treating kitchen waste and wastewater, using the system provided in Example 1, the specific process is as follows:

[0062] Firstly, the kitchen waste wastewater to be treated is discharged into the slurry tank 1 through the water inlet 11 of the slurry tank 1 . In the initial stage of the process, municipal sludge needs to be added. After the system runs stably, the scraping slag produced in the air flotation tank 5 and the sludge produced in the biochemical tank 6 can meet the demand for the use of activated sludge in the deodorization stage; in the slurry tank 1 Every cubic meter of kitchen waste wastewater is fully mixed with every cubic meter of activated sludge (stabilized sludge produced after domestication of sludge from municipal sewage plants) by stirring.

[0063] The mixed liquid is discharged into the three-phase screw dehydrator through the water outlet 12 of the slurry tank 1 and mixed with 1mg (per ton of water) pol...

Embodiment 3

[0068] This embodiment provides a process for treating kitchen waste and wastewater, using the system provided in Example 1, the specific process is as follows:

[0069] Firstly, the kitchen waste wastewater to be treated is discharged into the slurry tank 1 through the water inlet 11 of the slurry tank 1 . In the initial stage of the process, activated sludge needs to be added. After the system runs stably, the scraping slag produced by the air flotation tank 5 and the sludge produced by the biochemical tank 6 can meet the requirements for the use of activated sludge in the deodorization stage; Every cubic meter of food waste wastewater is fully mixed with every cubic meter of activated sludge (stabilized sludge produced after domestication of sludge from municipal sewage plants).

[0070] The mixed liquid is discharged into the feed port of the screw stack separator through the water outlet 12 of the slurry tank 1 and mixed with 1 mg (per ton of water) polyaluminium chloride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com