Treatment method of waste engine oil/lubricating oil regeneration distillation wastewater

A treatment method and technology of waste engine oil, applied in water/sewage treatment, biological water/sewage treatment, heating water/sewage treatment, etc., can solve problems such as heavy burden on enterprises, easy to block pipelines, outsourced disposal of hazardous waste, etc., and achieve The effect of saving disposal costs, reducing operating costs, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

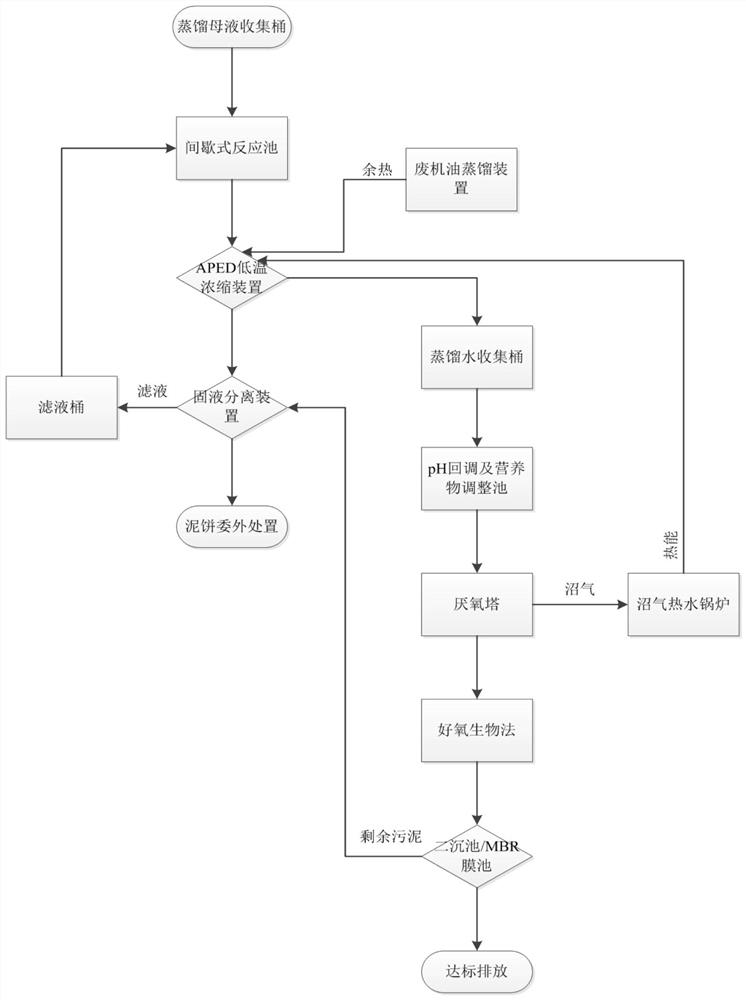

[0036] This embodiment according to figure 1 The waste engine oil / lubricating oil regeneration distillation wastewater is treated as indicated, and the waste engine oil / lubricating oil regeneration distillation wastewater has COD≥300,000mg / L, ammonia nitrogen≥5000mg / L, total nitrogen≥10000mg / L, and TDS≥20% . The process is as follows:

[0037] (1) Raw water pretreatment and evaporation:

[0038]Put waste engine oil / lubricating oil regenerated distillation wastewater into the batch reaction tank, add sulfuric acid (30wt.%) to the batch reaction tank to adjust the pH of the wastewater to 2-5;

[0039] (2) Sequentially batch waste water into the low-temperature evaporator for low-temperature evaporation. The heat source of the low-temperature evaporation equipment comes from the waste heat of the waste oil distillation equipment and the anaerobic tower biogas hot water boiler. After 70%-80% weight loss by evaporation, the evaporated distilled water is discharged to the distill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com