Calcium saponified organic phase clarification and extraction process and equipment thereof

The technology of extraction equipment and organic phase is applied in the field of calcium saponification organic phase clarification extraction process, which can solve the problems of difficulty in manual operation and complicated process, and achieve the effects of improving production efficiency, simple process and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further explained below in conjunction with specific examples.

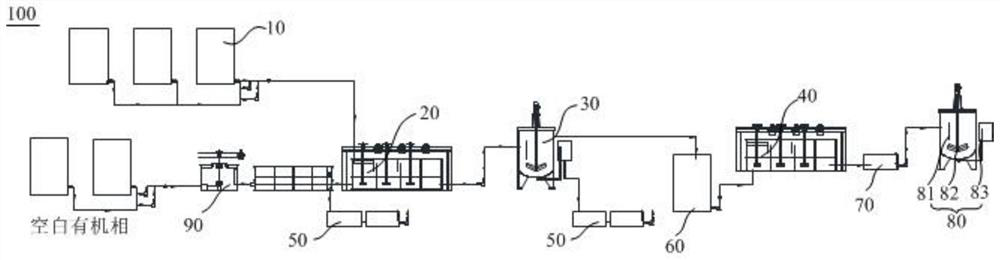

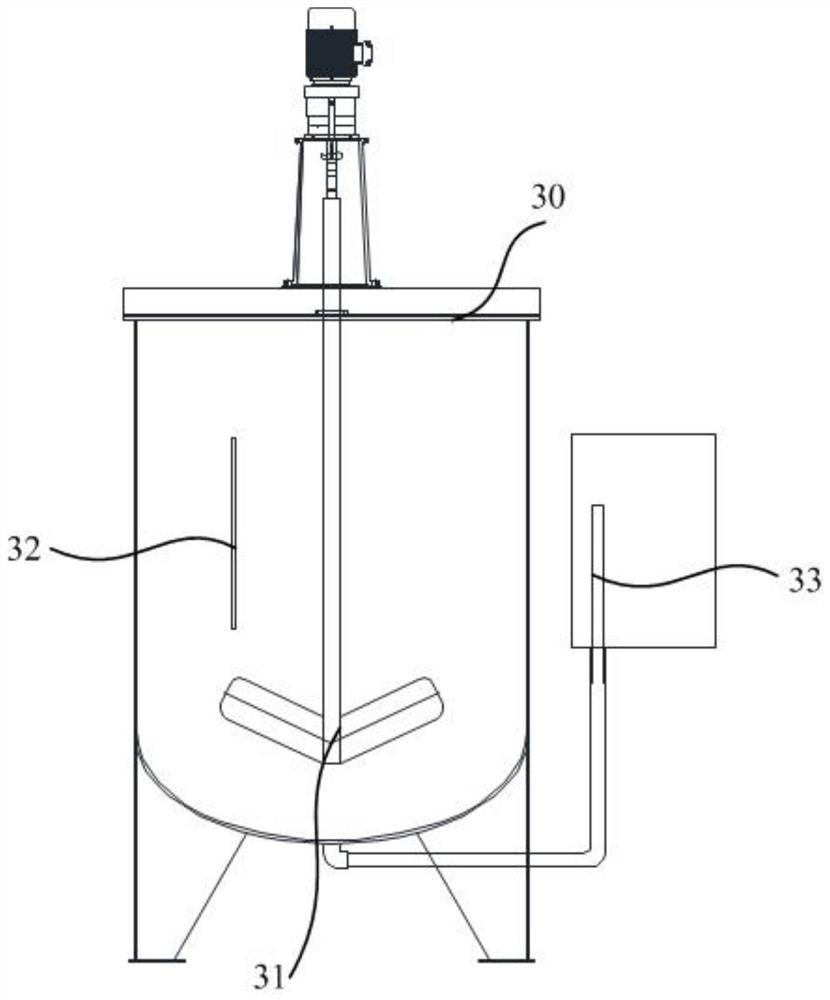

[0034] Such as figure 1 and figure 2 As shown, the present embodiment provides a calcium saponification organic phase clarification extraction process, comprising the following steps:

[0035] S1. A plurality of lime milk preparation tanks are used to prepare lime milk slurry, the concentration of the lime milk slurry is 4.91mol / L-5.11mol / L;

[0036] S2. Washing of the blank organic phase: The blank organic phase from the stripping section of the extraction production line is separated from the recovered rare earth soap and discarded water, and the raffinate and discarded water are fully stirred and mixed. Phase washing and discarding water;

[0037]S3, calcium saponification: put the lime milk slurry obtained in S1 and the blank organic phase obtained in S2 into the calcium soap tank for multi-stage co-flow continuous stirring and mixing to obtain the calcium saponificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com