Device and method for testing pure shear creep property of energetic material

A creep performance and pure shearing technology, which is applied in the direction of measuring devices, using stable shearing force to test the strength of materials, analyzing materials, etc., can solve the problem of connection with testing machines and other devices Adaptation and test methods are difficult to meet the needs of shear creep performance testing, continuous and reliable work, etc., to achieve the effect of simple and easy test methods, long-term stable and reliable tests, and shortened test cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

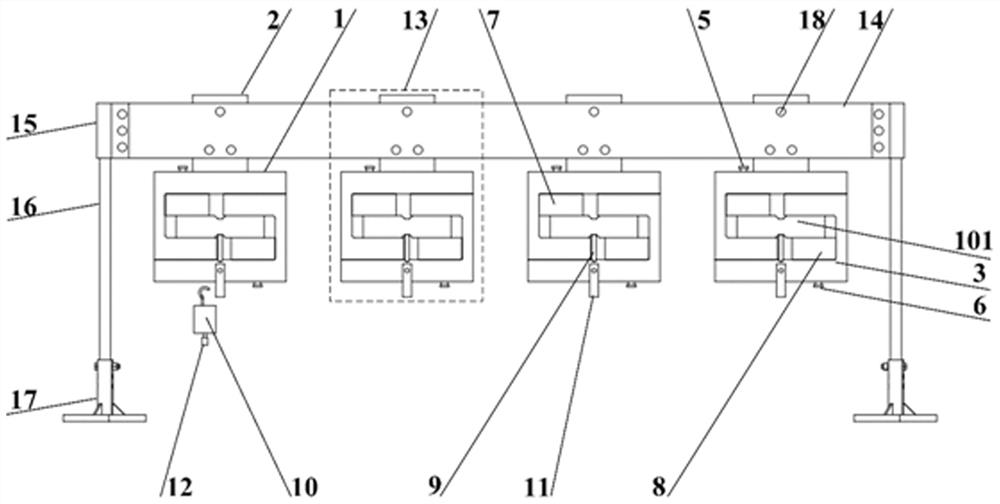

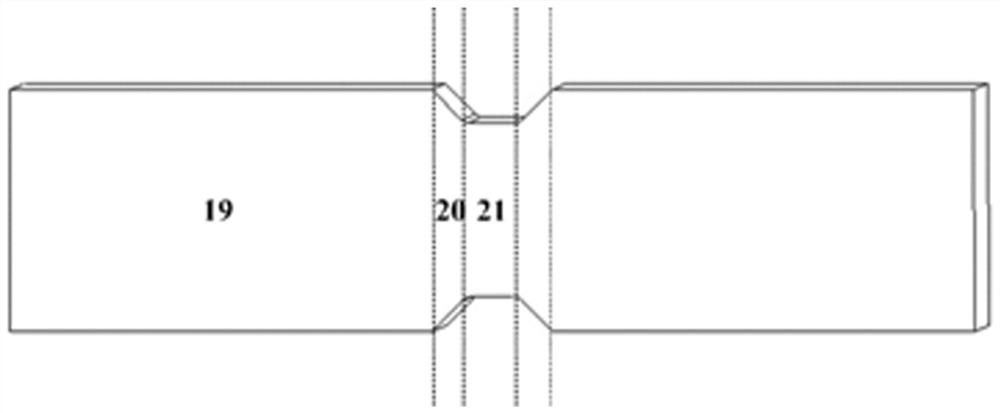

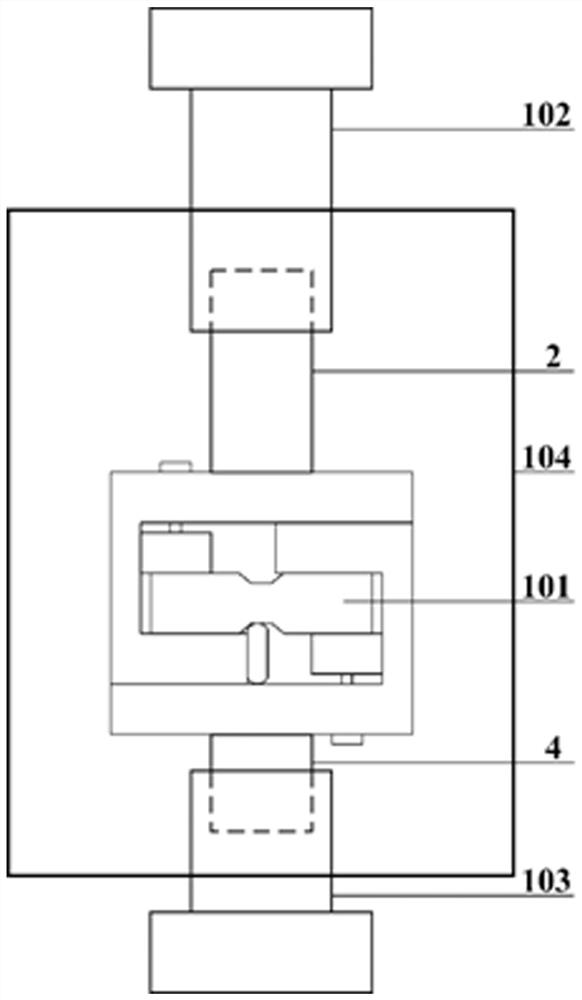

[0069] A device for testing the pure shear creep performance of energetic materials in the present invention includes a test fixture set 13, and the test fixture set 13 includes an upper fixture and a lower fixture that are matched and connected, and the area surrounded by the upper fixture and the lower fixture is a test parts holding area;

[0070] The upper clamp includes an upper clamping body 1 and an upper clamping part 2 fixedly connected with the support frame. The end of the upper clamping part 2 away from the support frame is fixedly connected with the upper clamping body 1. There is an upper accommodating opening for fixing one end of the test piece, and a test piece fixing device is arranged in the upper accommodating opening;

[0071] The lower fixture includes a lower clamp body 3 and a lower clamping portion 4, the lower clamp body 3 is connected to the upper clamp body 1 through a test piece arranged in the clamping area of the test piece, and the lower clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com