Preparation method of tire label composite material

A composite material and label technology, which is applied to the preparation of tire label composite materials, can solve the problems of short service life and poor use effect of tire labels, and achieve the effects of good protection effect, high production efficiency and bright metallic gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

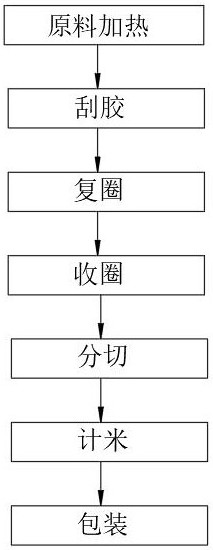

[0020] see figure 1 , the present invention provides a technical solution: a method for preparing a tire label composite material, the preparation method comprising the following steps: using a hot-melt pressure-sensitive adhesive as a raw material, which is a type of pressure-sensitive adhesive, mainly Synthetic rubber, resin and rubber oil are mixed and heated into a molten state. Hot-melt pressure-sensitive adhesives are the third generation of pressure-sensitive adhesive products after solvent-type and emulsion-type pressure-sensitive adhesives. Compared with the previous two, hot-melt pressure-sensitive adhesives Sensitive glue is solvent-free, which is more conducive to environmental protection and safe production. It has high production efficiency and relatively low production cost. It is used in conjunction with a hot-melt adhesive machine during specific preparation. The hot-melt adhesive machine is mainly used for hot-melt adhesive spraying, scraping, and rolling. Au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com