Terminal with stamping elastic sheet structure

A shrapnel and terminal technology, which is applied to the terminal field with a punched shrapnel structure, can solve the problems of unfavorable cost control of the charging system, can only be replaced as a whole, and long processing time, so as to save terminals and maintenance costs, save materials, and save processing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

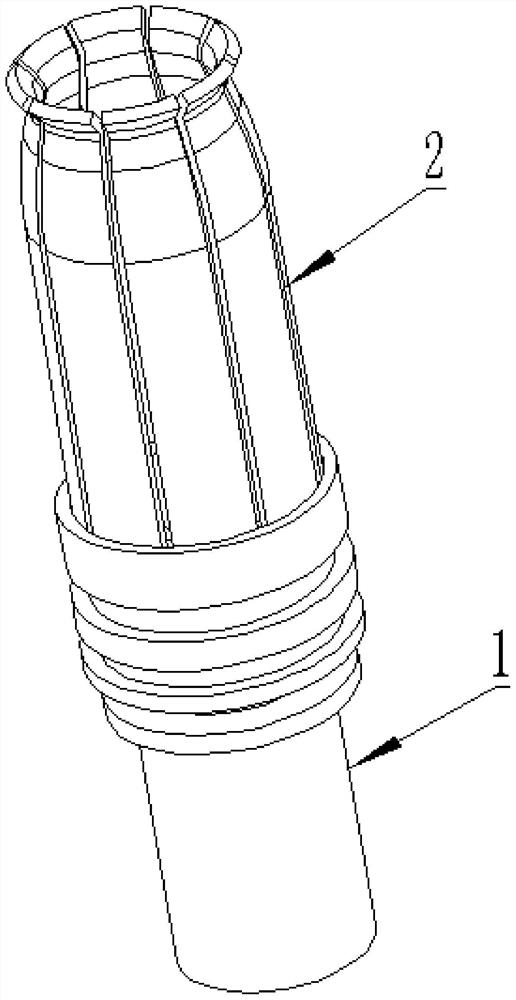

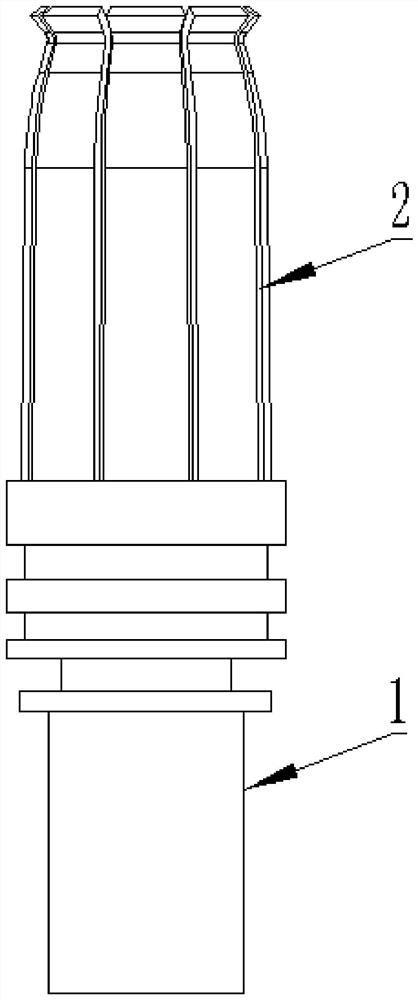

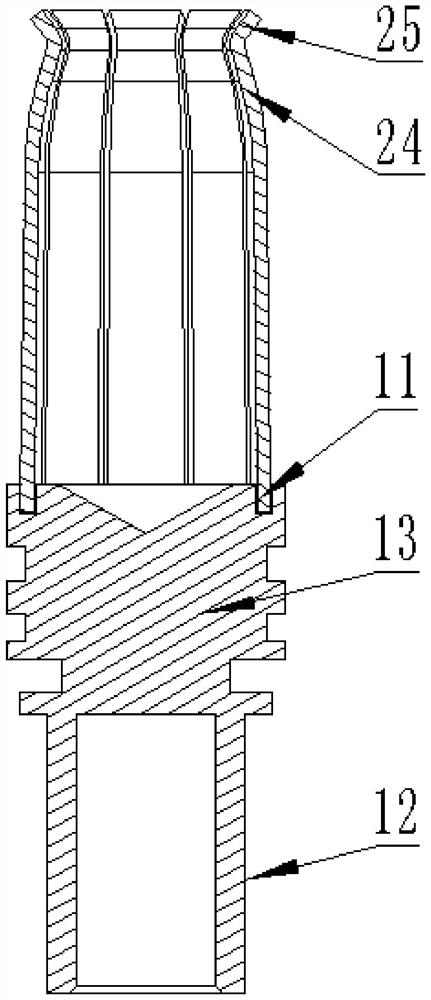

[0056] A terminal with a stamped spring structure, including a mounting base 1 and an outer spring structure 2, one end of the outer spring structure 2 is connected to one end of the installation base 1, the mounting base 1 and the outer spring structure 2 are formed separately, and the outer spring Structure 2 is a stamping and forming structure, such as Figure 1 to Figure 3 shown.

[0057] Among them, the installation base 1 and the outer shrapnel structure 2 are processed and formed separately, and then assembled into one body, and finally the terminal with the stamped shrapnel structure is formed, which greatly saves the cost of the terminal, reduces the processing time, and can also ensure that the shrapnel is compatible with the mating The conductive part of the terminal is in full contact.

[0058]In this embodiment, the outer elastic structure 2 is cylindrical. Along the circumferential direction of the outer elastic structure 2, the outer elastic structure 2 contain...

Embodiment 2

[0090] This embodiment is an improvement to Embodiment 1. The main difference between this embodiment and Embodiment 1 is that this embodiment adds an inner shrapnel structure 3 on the basis of Embodiment 1, that is, the inner shrapnel structure 3 containing the punched shrapnel structure. The terminal also includes an inner shrapnel structure 3, which is stacked with the outer shrapnel structure 2, one end of the inner shrapnel structure 3 is connected to the installation base 1, or one end of the inner shrapnel structure 3 is connected to the outer shrapnel structure 2, or the inner shrapnel One end of the structure 3 is connected with the installation base 1 and the outer shrapnel structure 2, such as Figure 10 and Figure 11 shown.

[0091] Since the outer shrapnel structure 2 is generally stamped and formed, limited by the thickness of the plate, the thickness of the outer shrapnel structure 2 may not be able to meet the gripping force requirements of the terminal with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com