Manual arc welding power supply with arc control function

An arc control and manual arc welding technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of arc breakage, poor welding seam formation, substandard workpieces, etc., and achieve the effect of increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

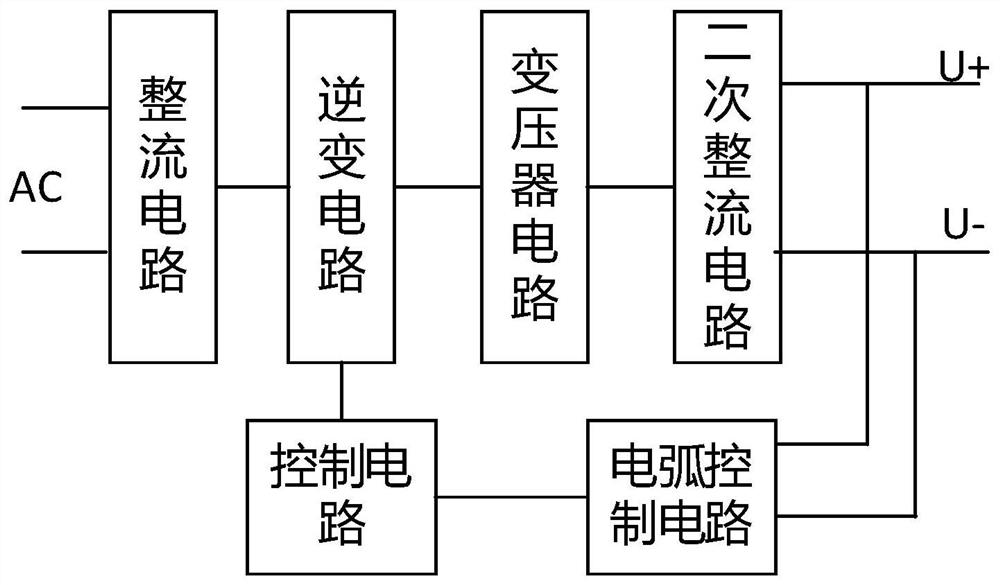

[0028] A kind of manual arc welding power supply with arc control function of the present application, such as figure 1 As shown, including rectification circuit, inverter circuit, transformer circuit, secondary rectification circuit, control circuit, arc control circuit, rectification circuit, inverter circuit, transformer circuit, secondary rectification circuit are connected in sequence, and the output of the control circuit is connected to the inverter The input of the circuit is connected to the output of the arc control circuit, and the input of the arc control circuit is connected to the output of the secondary rectification circuit.

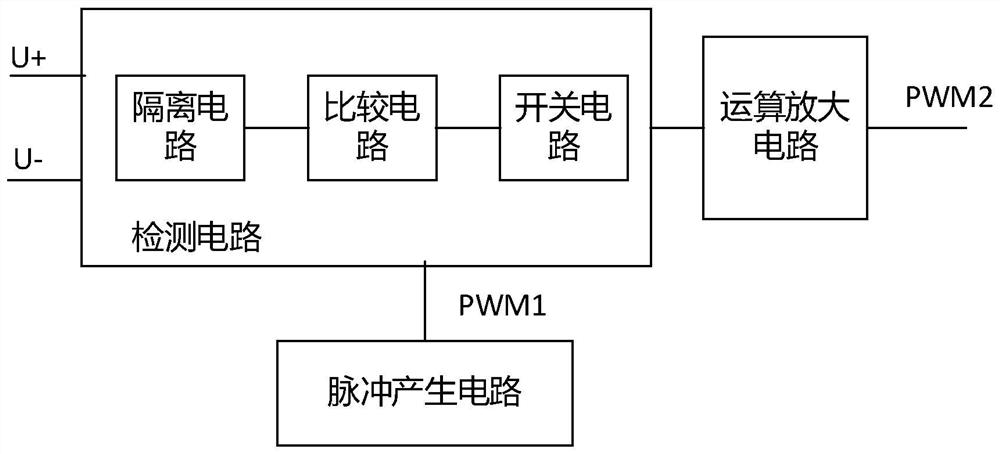

[0029] The arc control circuit is used to detect the output voltage of the secondary rectification circuit, that is, the output voltage of the manual arc welding power supply. When the output voltage is detected to drop, it outputs a constant pulse signal to the control circuit. The control circuit controls the conduction time of the powe...

specific Embodiment 2

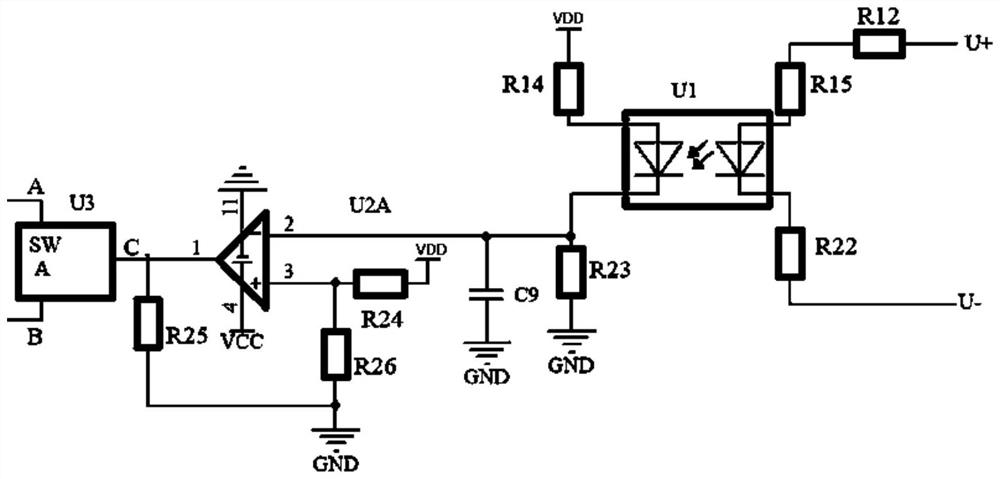

[0045] In a specific embodiment of the present application, the detection circuit in the arc control circuit, such as image 3 As shown, including optocoupler U1, first comparator U2A, resistors R12 / R15 / R22 form the first voltage divider circuit, resistors R14 / R23 form the second voltage divider circuit, resistors R24 / R26 form the voltage setting circuit.

[0046] After the resistors R12 / R15 are connected in series, one end is connected to the positive output end of the secondary rectification circuit, the other end is connected to the input end of the input side of the optocoupler U1, the output end of the input side of the optocoupler U1 is connected to one end of the resistor R22, and the other end of the resistor R22 Connect to the negative output terminal of the secondary rectification circuit.

[0047] The output voltage of the secondary rectification circuit determines the current flowing through the first voltage divider circuit. When the output voltage of the secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com