A continuous seamless rigid contact suspension net system for rail transit and its installation method

A rigid contact and rail transit technology, applied in the direction of overhead lines, etc., can solve problems such as the degradation of the dynamic performance of the pantograph-catenary system, achieve the effects of reducing fault links and operation and maintenance workload, improving reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

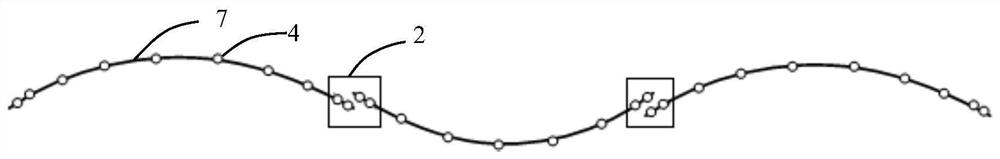

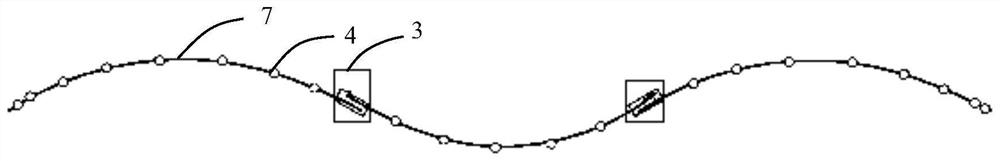

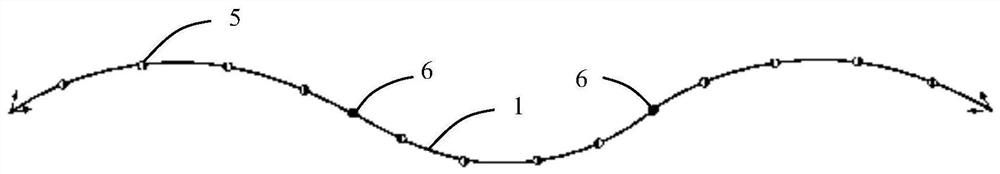

[0041] A rail transit rigid catenary suspension system includes an expansion section 1 and an insulating anchor joint 6 . The two adjacent expansion sections 1 are fixedly connected by an anchoring joint 6, the anchoring joint 6 has a "T"-shaped structure, and the anchoring joint 6 is also fixedly connected with the support structure. The system consists of multiple expansion sections 1. like image 3As shown, the bending directions of the two expansion sections 1 connected by the anchor joint 6 are opposite, and the smooth transition forms a wave shape (preferably, the wave shape is a sine wave), so that the expansion section 1 acts on the anchorage due to the bending deformation The forces on the joint 6 can cancel each other out. The expansion section 1 includes a bus bar connected by welding, a contact wire is installed in the bus bar, and the bus bar and the contact wire form a rigid contact network; a plurality of sliding positioners 5 are also connected to the bus bar...

Embodiment 2

[0046] An installation method for a continuous seamless rigid contact suspension net system for rail transit, comprising step S1: according to line conditions (the line is a straight line, a curve and an easing curve), the highest and lowest temperature of the operating line environment, and the allowable temperature of the expansion section 1 when working Maximum pull-out value Z max with the minimum pull-out value Z min , calculate the distance between the two adjacent anchor joints 6; S2: Install the anchor joint 6 on the support structure according to the distance between the two adjacent anchor joints 6, and install the sliding positioning on the support structure between the two anchor joints 6 Device 5; S3: Determine the value range of the initial pull-out value of the expansion section 1 according to the annual average air temperature at the installation site; S4: Fix one end of the expansion section 1 (that is, one end of the busbar in the expansion section 1) on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com