An epoxy-based two-dimensional sheet metal nano-filler with ultra-high isotropic thermal conductivity material and preparation method thereof

A flake metal and nano-filler technology, applied in the field of thermally conductive materials, can solve the problems of unsuitable high-efficiency thermal interface materials, complicated preparation methods, poor thermal conductivity, etc., achieve good commercial application prospects, simple preparation methods, and improve thermal conductivity performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In this embodiment, an epoxy-based two-dimensional sheet-shaped metal nanofiller with ultra-high isotropic thermal conductivity mainly includes the following components in parts by weight:

[0060]

[0061] Wherein, described epoxy resin selects bisphenol A type epoxy resin,

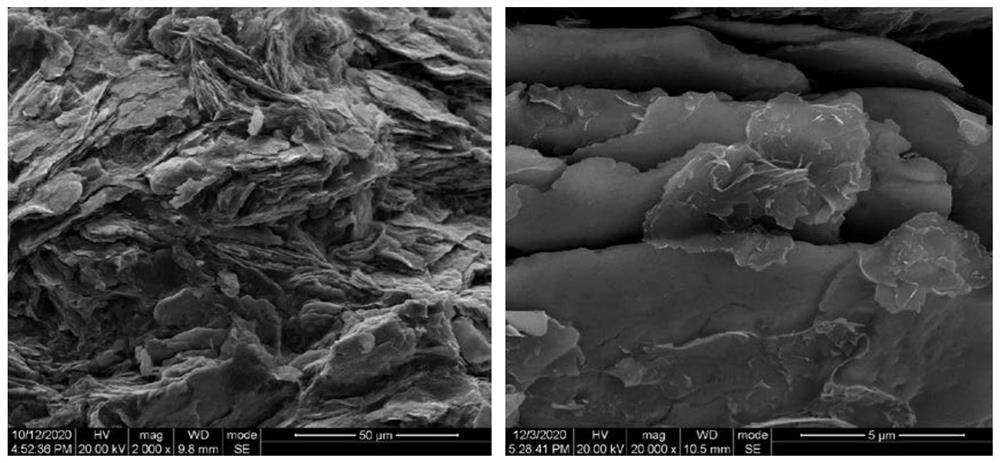

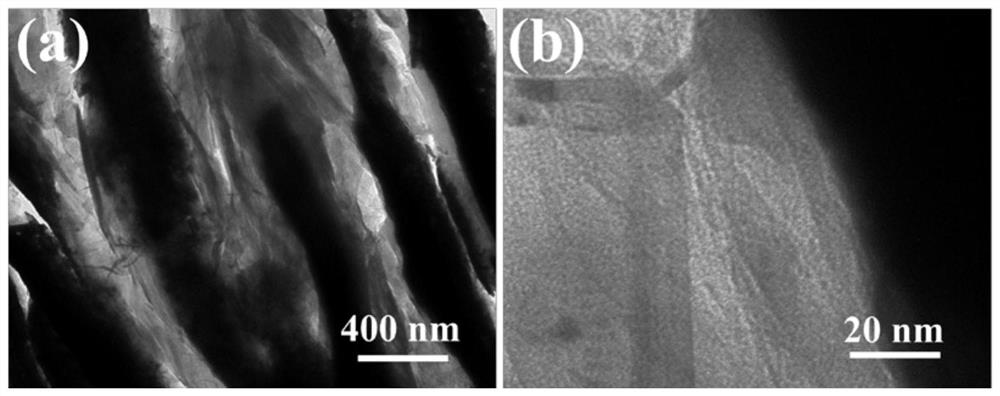

[0062] The two-dimensional flaky metal nanofiller is selected from two-dimensional flaky metal iron nanosheets with an average sheet thickness of 100-300 nm and an average outer diameter of 10-15 μm.

[0063] The two-dimensional flaky carbon-based thermally conductive filler is selected from two-dimensional flaky graphene with an average sheet thickness of 10-50 nm and an average outer diameter of 1-10 μm.

[0064] Described diluent selects sherwood oil.

[0065] The preparation method of the above-mentioned epoxy-based two-dimensional flake metal nano-filler ultra-high isotropic thermal conductivity material mainly includes the following steps:

[0066] (1) Compound epoxy resin, two-dimensio...

Embodiment 2

[0071] In this embodiment, an epoxy-based two-dimensional sheet-shaped metal nanofiller with ultra-high isotropic thermal conductivity mainly includes the following components in parts by weight:

[0072]

[0073] Wherein, the epoxy resin is selected aromatic heterocyclic epoxy resin,

[0074] The two-dimensional sheet metal nanofiller is selected from two-dimensional sheet metal silver nanosheets with an average sheet thickness of 100-200 nm and an average outer diameter of 10-15 μm.

[0075] The two-dimensional flaky carbon-based thermally conductive filler is selected from two-dimensional flaky micron graphite flakes with an average sheet thickness of 50-500 nm and an average outer diameter of 1-10 μm.

[0076] Described diluent selects ethanol.

[0077] The preparation method of the above-mentioned epoxy-based two-dimensional flake metal nano-filler ultra-high isotropic thermal conductivity material mainly includes the following steps:

[0078] (1) Compound epoxy resi...

Embodiment 3

[0083] In this embodiment, an epoxy-based two-dimensional sheet-shaped metal nanofiller with ultra-high isotropic thermal conductivity mainly includes the following components in parts by weight:

[0084]

[0085] Wherein, described epoxy resin selects bisphenol F type epoxy resin,

[0086] The two-dimensional flaky metal nanofiller is selected from two-dimensional flaky metal aluminum nanosheets with an average sheet thickness of 100-200 nm and an average outer diameter of 10-20 μm.

[0087] The two-dimensional flaky carbon-based thermally conductive filler is selected from two-dimensional flaky expanded graphite with an average sheet thickness of 50-500 nm and an average outer diameter of 1-10 μm.

[0088] The diluent is n-hexane.

[0089] The preparation method of the above-mentioned epoxy-based two-dimensional flake metal nano-filler ultra-high isotropic thermal conductivity material mainly includes the following steps:

[0090] (1) Compound epoxy resin, two-dimension...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com