Graphite negative electrode material, preparation method thereof and secondary battery

A graphite negative electrode and graphitization technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of high OI value of materials and difficulty in overcoming the orientation characteristics of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

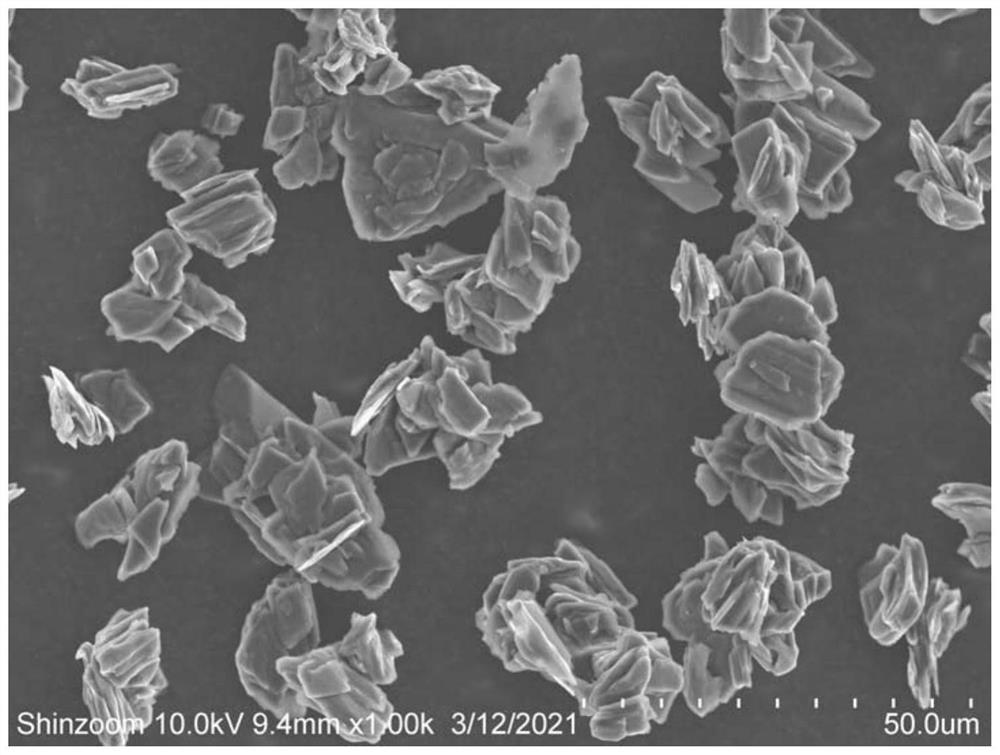

Image

Examples

preparation example Construction

[0021] A preparation method of a graphite negative electrode material comprises the first-stage fluidization, the second-stage fluidization and graphitization.

[0022] Specifically, aggregate particles and asphalt particles with a mass ratio of (80-98):(2-20) are fluidized in the first stage at 150-350°C in an inert atmosphere; at 400-800°C, inert The second stage of fluidization is carried out in the atmosphere; then graphitization is carried out in an inert atmosphere; wherein, the particle size of the asphalt particles D50 is 2-20 μm.

[0023] In this application, both the first-stage fluidization and the second-stage fluidization refer to making the material in a fluidized state. For example, in fluidization equipment, the material is in a fluidized state. In the embodiment of the present application, the mass ratio of aggregate particles to asphalt particles can be 80:10, 85:15, 86:14, 87:13, 90:10, 92:8, 93:7, 95:5 , 98:2 and so on.

[0024] Exemplarily, in some embo...

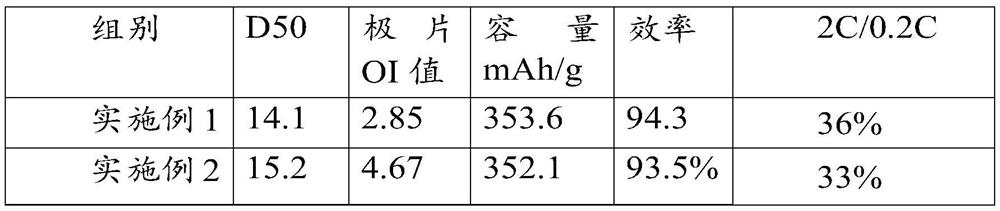

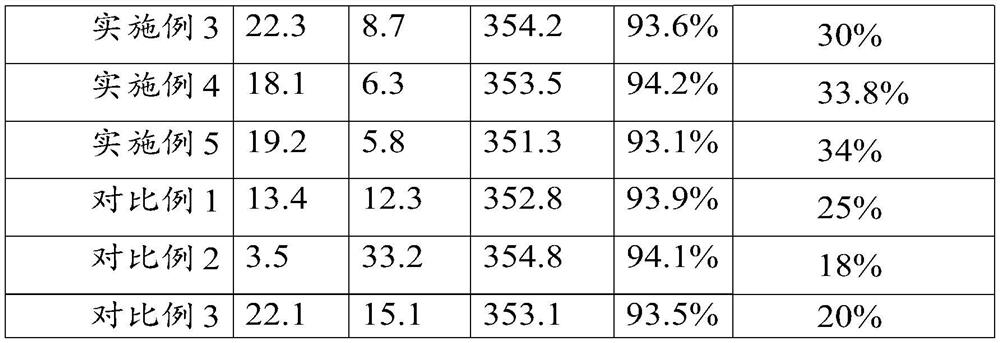

Embodiment 1

[0051] This embodiment provides a graphite negative electrode material, which is mainly prepared by the following method:

[0052] 1) Take 800g of green coke with a D50 particle size of 4μm and 200g of asphalt with a particle size of 20μm and mix them evenly.

[0053] 2) Put the material obtained in step 1) in a fluidized bed equipment, raise the temperature to 150° C. at a heating rate of 5° C. / min, fill the fluidized bed with nitrogen, and fluidize it for 6 hours at an air velocity of 5 L / min.

[0054] 3) The temperature was raised to 400° C. at a heating rate of 1° C. / min, and nitrogen was filled into the fluidized bed at an air velocity of 5 L / min, and fluidized for 5 hours.

[0055] 4) Put the material obtained in step 3) into a graphitization furnace for graphitization, the temperature of graphitization is 2800° C., and the time is 40 h.

[0056] 5) Coating the obtained graphitized particles with carbon, then sieving to obtain a material with Dmax≤30 μm, and then demagn...

Embodiment 2

[0059] This embodiment provides a graphite negative electrode material, which is mainly prepared by the following method:

[0060] 1) Take 850g of green coke with a D50 particle size of 8μm and 150g of asphalt with a particle size of 2μm and mix them evenly.

[0061] 2) Put the material obtained in step 1) in a fluidized bed equipment, raise the temperature to 350° C. at a heating rate of 10° C. / min, fill the fluidized bed with nitrogen, and fluidize it for 8 hours at an air velocity of 6 L / min.

[0062] 3) The temperature was raised to 800° C. at a heating rate of 10° C. / min, and nitrogen was filled into the fluidized bed at an air velocity of 6 L / min, and fluidized for 5 hours.

[0063] 4) Put the material obtained in step 3) into a graphitization furnace for graphitization, the graphitization temperature is 3100° C., and the time is 20 hours.

[0064] 5) Coating the obtained graphitized particles with carbon, then sieving to obtain a material with Dmax≤40 μm, and then dema...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com