Composite wave-absorbing agent with electromagnetic wave-absorbing performance, and preparation method thereof

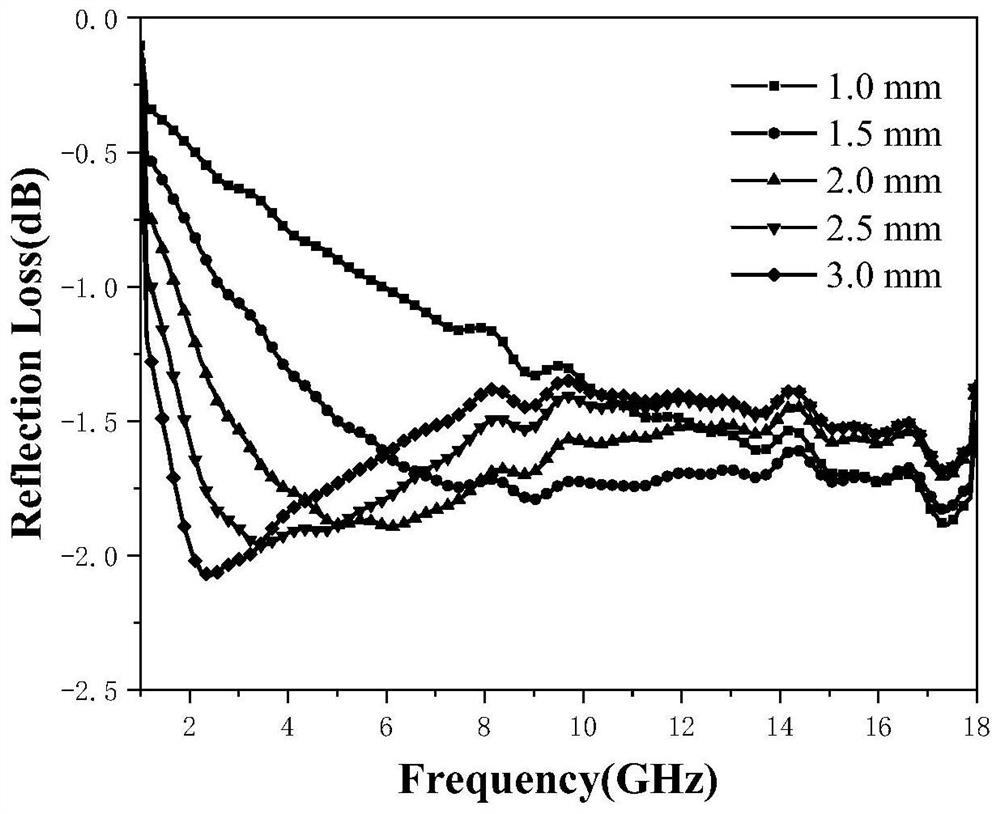

A technology of electromagnetic absorbing and absorbing agent, which is applied in the direction of electrical components, magnetic/electric field shielding, antennas, etc., and can solve problems such as high density, single loss mechanism, and limited absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of a composite wave-absorbing agent with electromagnetic wave-absorbing properties of the present invention comprises the following steps:

[0029] Step 1. Put Ti 3 AlC 2 The powder is mixed with hydrofluoric acid to obtain a mixed solution A;

[0030] In step 1, every 40mL of hydrofluoric acid needs 10mmol of Ti 3 AlC 2 .

[0031] Step 2. Stir the mixed solution A continuously for 24-30 hours at room temperature to obtain the mixed solution B;

[0032] In step 2, the stirring speed is 200-400r / min.

[0033] Step 3. Under the rotating speed of 4500-6500r / min, use a centrifuge to repeatedly centrifuge and wash the mixed solution B with deionized water until the pH value of the liquid is 6-7;

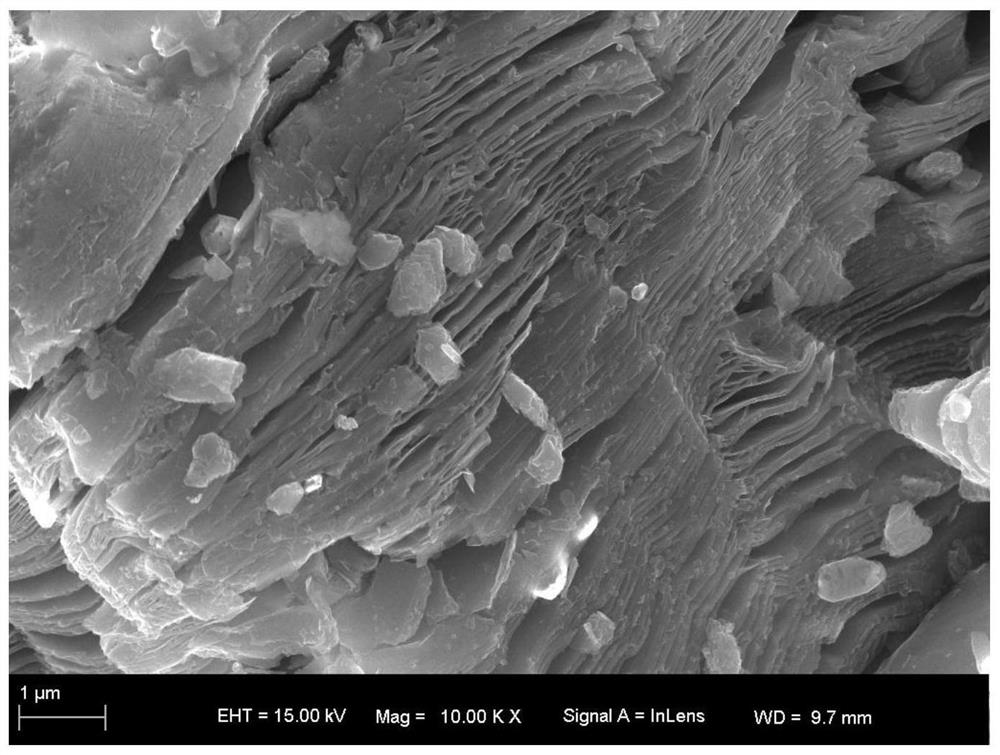

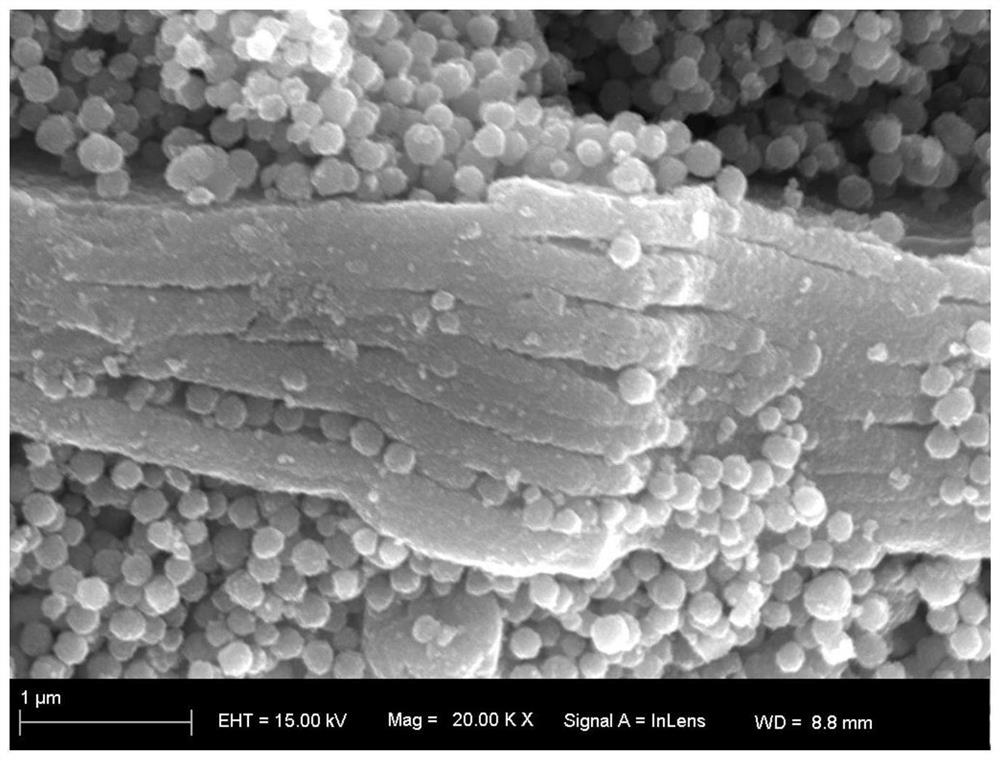

[0034] Step 4, the centrifuged product obtained in step 3 is dried in an oven to obtain a two-dimensional layered Ti 3 C 2 T X , the layered structure is conducive to the reflection and scattering of electromagnetic waves, T X refers to the exposed Ti...

Embodiment 1

[0046] A preparation method of a composite wave-absorbing agent with electromagnetic wave-absorbing properties, comprising the following steps:

[0047] Step 1. Put Ti 3 AlC 2 The powder is mixed with hydrofluoric acid to obtain a mixed solution A;

[0048] In step 1, every 40mL of hydrofluoric acid needs 10mmol of Ti 3 AlC 2 .

[0049] Step 2. Stir the mixed solution A continuously for 24 hours at room temperature to obtain the mixed solution B;

[0050] In step 2, the stirring speed is 200r / min.

[0051] Step 3. At a rotational speed of 4500r / min, use a centrifuge to repeatedly centrifuge and wash the mixed solution B with deionized water until the pH value of the liquid is 6;

[0052] Step 4, the centrifuged product obtained in step 3 is dried in an oven to obtain Ti 3 C 2 T X ;

[0053] In step 4, the drying temperature is 60° C.; the drying time is 10 hours.

[0054] Step 5, weigh raw materials according to the following molar mass ratio: CoCl 2 ·6H 2 O: FeCl...

Embodiment 2

[0065] A preparation method of a composite wave-absorbing agent with electromagnetic wave-absorbing properties, comprising the following steps:

[0066] Step 1. Put Ti 3 AlC 2 The powder is mixed with hydrofluoric acid to obtain a mixed solution A;

[0067] In step 1, every 40mL of hydrofluoric acid needs 10mmol of Ti 3 AlC 2 .

[0068] Step 2. Stir the mixed solution A continuously for 30 hours at room temperature to obtain the mixed solution B;

[0069] In step 2, the stirring speed is 400r / min.

[0070] Step 3. At a rotational speed of 6500r / min, use a centrifuge to repeatedly centrifuge and wash the mixed solution B with deionized water until the pH value of the liquid is 7;

[0071] Step 4, the centrifuged product obtained in step 3 is dried in an oven to obtain Ti 3 C 2 T X ;

[0072] In step 4, the drying temperature is 70° C.; the drying time is 8 hours.

[0073] Step 5, weigh raw materials according to the following molar mass ratio: CoCl 2 ·6H 2 O: FeCl 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com