Biological enzyme composite disinfectant as well as preparation method and application thereof

A disinfectant and biological enzyme technology, applied in the fields of botanical equipment and methods, disinfectants, biocides, etc., can solve the problems of slow action process, low disinfection efficiency, unfavorable large-scale application, etc. The effect of antibacterial sterilization and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

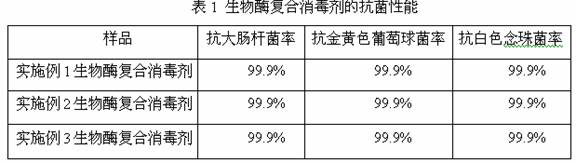

Examples

Embodiment 1

[0054] Dissolve loquat leaves, bamboo leaves, dandelion, and Houttuynia cordata in deionized water, heat to 100°C and boil for 30 minutes, then let cool; add lysozyme and clover plant extract to the above-mentioned cooled water in sequence, and stir magnetically 1 h, until the solution is mixed evenly; add lavender spice as needed, stir evenly and divide into packages.

[0055] A formula (parts by mass) of a preparation method of a biological enzyme compound disinfectant:

[0056] 4 parts loquat leaves

[0057] Bamboo leaves 5 parts

[0058] 3 servings dandelions

[0059] Houttuynia cordata 2 parts

[0060] Lysozyme 8 parts

[0061] Clover plant extract 3 parts

[0062] Lavender spice 0.2 parts

[0063] Deionized water was added to 100 parts.

Embodiment 2

[0065] Dissolve loquat leaves, bamboo leaves, dandelion, and Houttuynia cordata in deionized water, heat to 100°C and boil for 60 minutes, then let cool; add lysozyme and panax notoginseng plant extract to the above-mentioned cooled water in sequence, and stir magnetically 2 h, until the solution is mixed evenly; add jasmine spice as needed, stir evenly and divide into packages.

[0066] A formula (parts by mass) of a preparation method of a biological enzyme compound disinfectant:

[0067] Loquat leaves 6 parts

[0068] 3 parts bamboo leaves

[0069] 4 servings dandelions

[0070] Houttuynia cordata 1 part

[0071] 5 parts lysozyme

[0072] Panax notoginseng plant extract 5 parts

[0073] Jasmine spice 0.3 parts

[0074] Deionized water was added to 100 parts.

Embodiment 3

[0076] Dissolve loquat leaves, bamboo leaves, dandelion, and Houttuynia cordata in deionized water, heat to 100°C and boil for 60 minutes, then let cool; add lysozyme and clover plant extract to the above-mentioned cooled water in sequence, and stir magnetically 2 h, until the solution is mixed evenly; add rose spice as needed, stir evenly and divide into packages.

[0077] A formula (parts by mass) of a preparation method of a biological enzyme compound disinfectant:

[0078] Loquat leaves 5 parts

[0079] 4 bamboo leaves

[0080] 3 servings dandelions

[0081] Houttuynia cordata 2 parts

[0082] 6 parts lysozyme

[0083] 3 parts of clover plant extract

[0084] Rose spice 0.2 parts

[0085] Deionized water was added to 100 parts.

[0086]

[0087] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com