Process method for preparing high-performance medical UV adhesive

A process method and adhesive technology, applied in the field of medical articles, can solve the problems of adhesive waste, unusable medical adhesive, and easy oxidation, so as to improve anti-aging and anti-oxidation and reduce wound infection The risk of bacteria, the effect of prolonging the effective use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

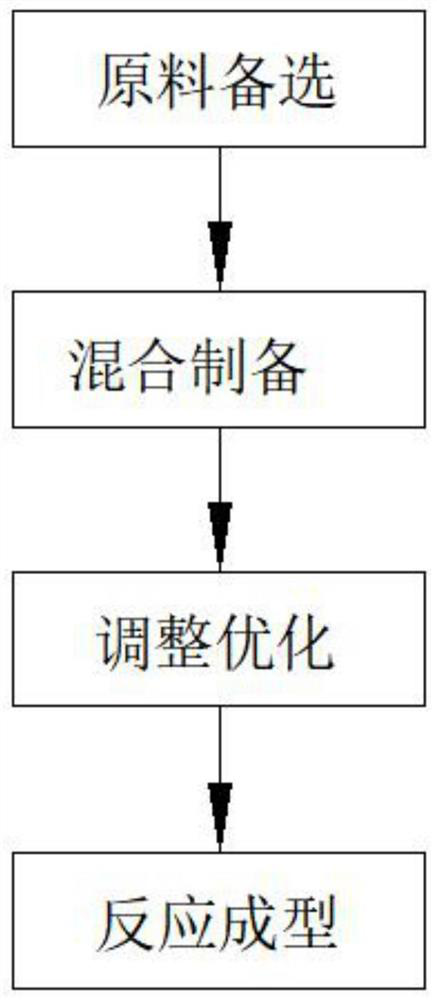

[0018] Embodiment 1, with reference to figure 1 , a process method for preparing a high-performance medical UV adhesive, comprising the following steps:

[0019] Step 1: raw materials are optional, get the following raw materials for optional, 80 parts of n-butyl cyanoacrylate, 30 parts of A type tackifying resin, 10 parts of B type tackifying resin, 2 parts of sulfur dioxide, 3 parts of hydroquinone 5 parts, 5 parts of softening agent, 1 part of antioxidant, 1 part of antioxidant and 5 parts of plasticizer, what the plasticizer in described step 1 adopted is phthalate plasticizer;

[0020] Step 2: mixed preparation, after pouring 80 parts of optional α-n-butyl cyanoacrylate into the reaction vessel, first pour 30 parts of Class A tackifying resin into the reaction vessel, then raise the temperature and then Mix and stir, add B-type tackifying resin evenly during the stirring process, and obtain mixture N after mixing, add sulfur dioxide and hydroquinone to the mixture and st...

Embodiment 2

[0023] Embodiment 2, with reference to figure 1 , a process method for preparing a high-performance medical UV adhesive, comprising the following steps:

[0024] Step 1: raw materials are optional, get the following raw materials for optional, 90 parts of n-butyl cyanoacrylate, 40 parts of A-type tackifying resins, 20 parts of B-type tackifying resins, 3 parts of sulfur dioxide, 4 parts of hydroquinone part, 10 parts of softening agent, 2 parts of antioxidant, 2 parts of antioxidant and 8 parts of plasticizer, what the plasticizer in described step 1 adopted is phthalate plasticizer;

[0025] Step 2: mixed preparation, after pouring 90 parts of optional α-n-butyl cyanoacrylate into the reaction vessel, first pour 40 parts of Type A tackifying resin into the reaction vessel, then raise the temperature and then Mix and stir, add B-type tackifying resin evenly during the stirring process, and obtain mixture N after mixing, add sulfur dioxide and hydroquinone to the mixture and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com