A control method of wet screening and dry crushing sand making process in fine crushing workshop of machine-made sand and gravel

A control method and workshop technology, applied in wet separation, chemical instruments and methods, solid separation, etc., can solve problems such as low crushing efficiency, lack of quality control means, and inability to meet the requirements of high-quality machine-made sand and gravel processing, and achieve reduction The effect of regulating costs and improving control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention are further described below, but the claimed scope is not limited to the description.

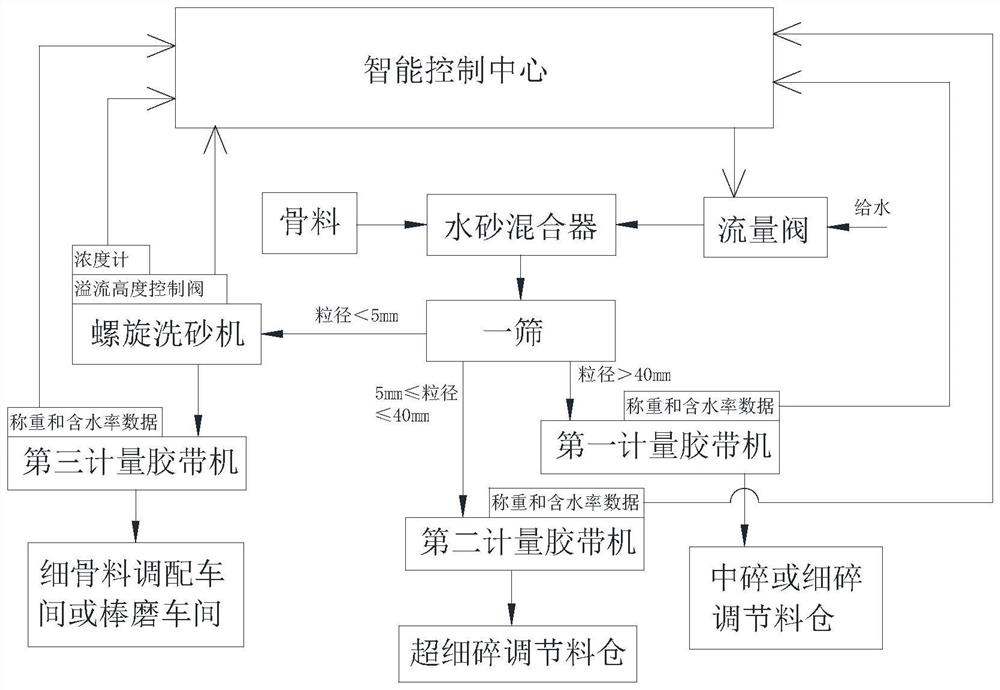

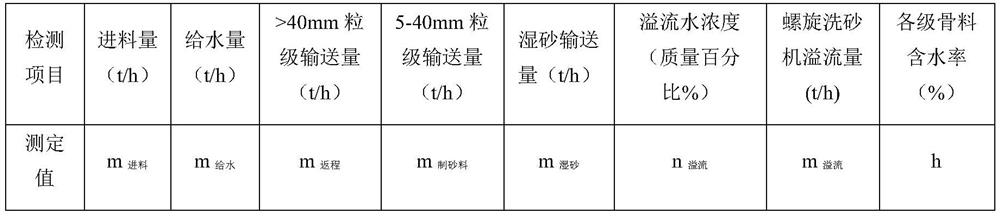

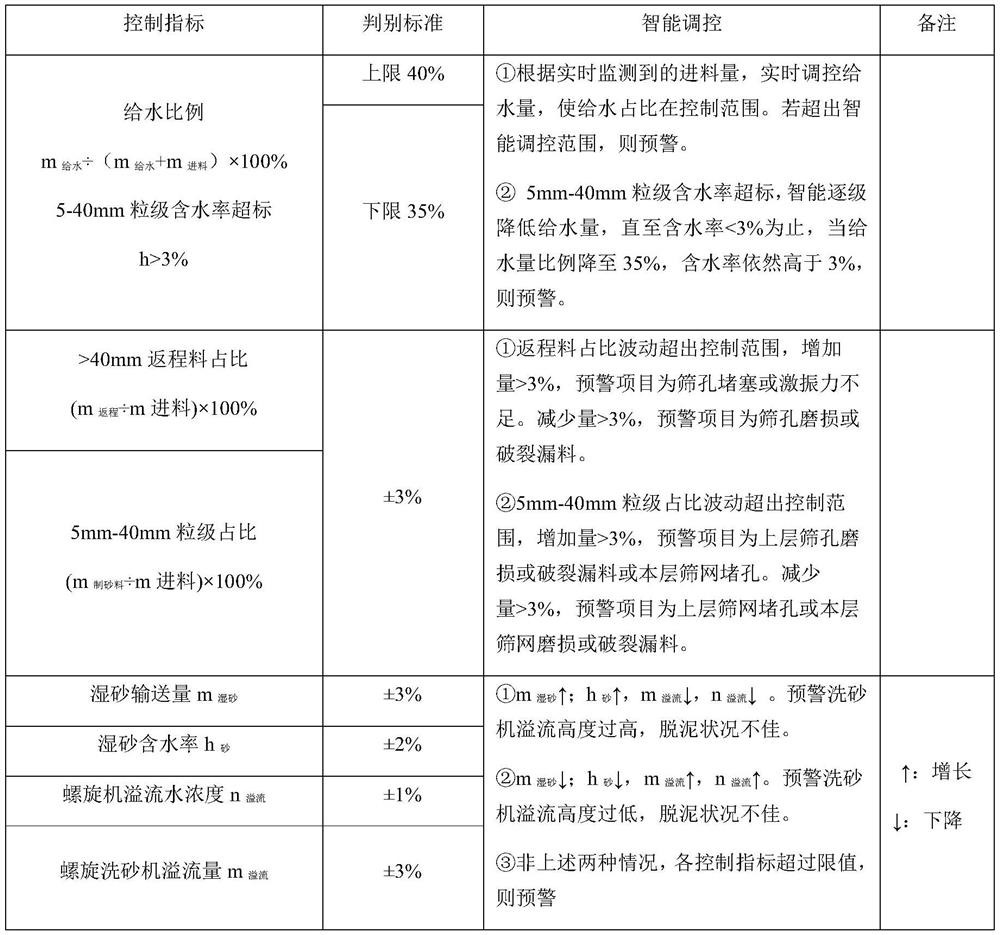

[0019] like figure 1 As shown in the figure, a method for controlling the wet-screening and dry-breaking sand-making process in a medium-fine crushing workshop of machine-made sand and gravel includes the following steps: the crushed aggregate from the medium-fine crushing workshop is transported to a water-sand mixer to be mixed with water, and then passed through a sieve. After that, it is sent to all parts of the workshop by the metering belt conveyor. The water content detector is installed on the metering belt conveyor. The inlet pipe of the water-sand mixer is equipped with a flow valve. The rate control range and intelligent regulation table are collected, and the weighing and moisture content data of the measuring tape machine are collected in real time, and the water flow rate of the flow valve is controlled according to the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com