High-strength high-temperature-resistant composite material air inlet channel and forming method thereof

A technology of composite materials and molding methods, which can be used in the combustion of air intakes of power devices, other household appliances, and other applications. It can solve the problems of material selection and molding process limitations for air intakes, and achieve good process stability and structural strength. And the effect of improving temperature resistance and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

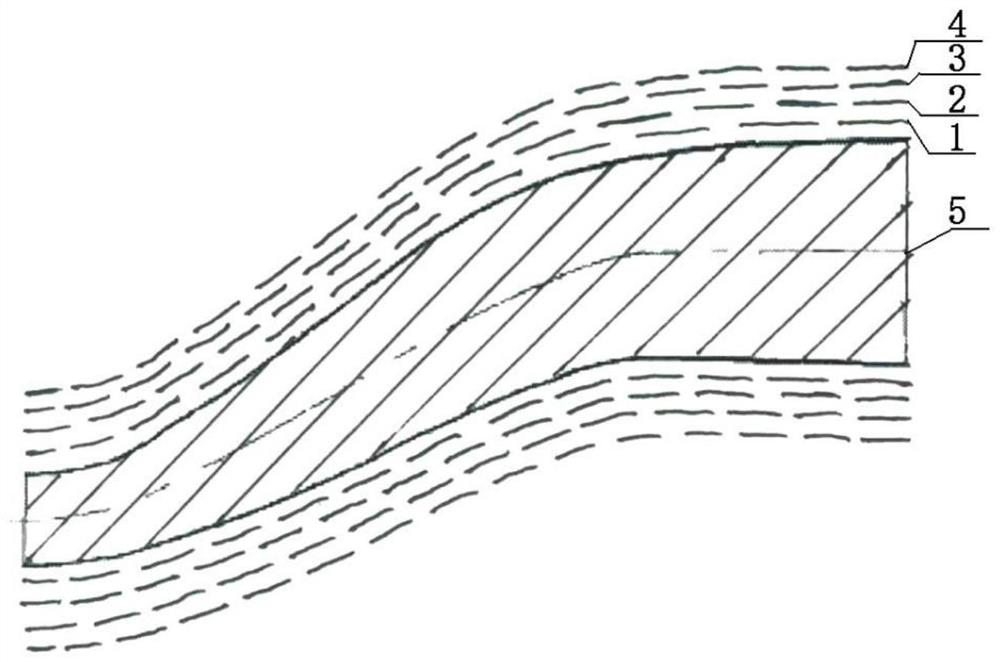

[0031] This example is made as figure 1 In the air inlet of a high-strength and high-temperature-resistant composite material shown, the diameter of the outlet end is 300 mm, and the inlet end is elliptical with a long circle of 150 mm and a short circle of 80 mm. The wall thickness of the air inlet is 4mm. The composite material is quartz fiber / cyanate resin.

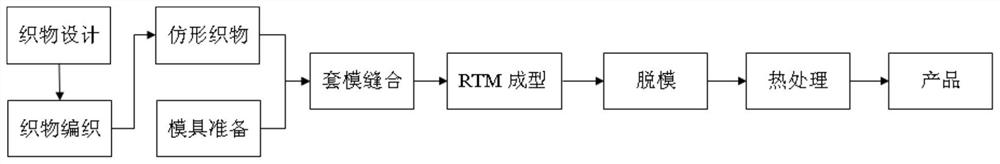

[0032] The forming process of the inlet duct is as follows: figure 2 As shown, the specific steps are as follows:

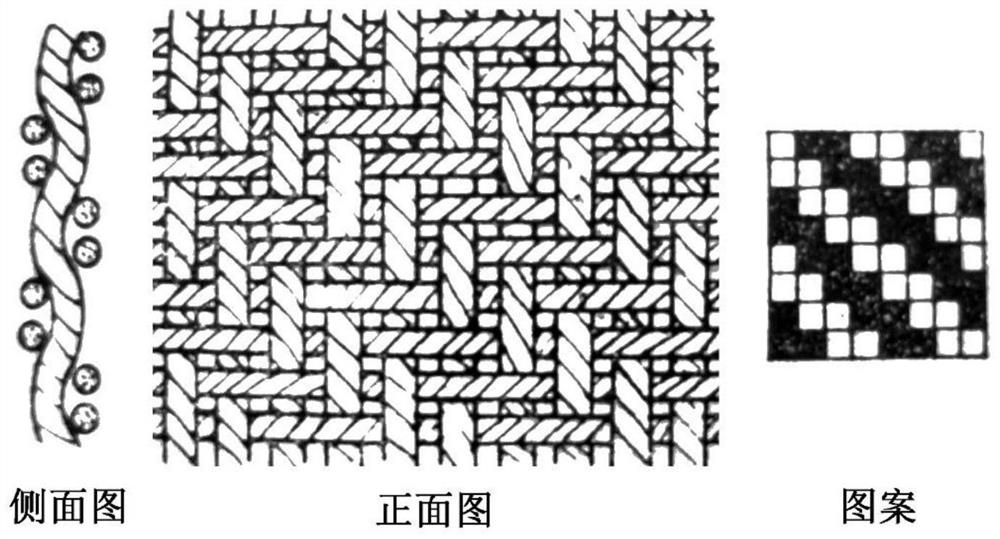

[0033] Step 1: According to the overall thickness d of the product 总 and operating experience, the number of layers is designed to be 4, and the calculated d 单 = 1 mm. Profile offset d using 3D model 单 The distance of is to get the outline shape of each cloth layer. designed using image 3 For the 2D weaving method shown, the cloth layers from the inner surface to the outer surface are recorded as cloth layers 1, 2, 3, and 4 in sequence;

[0034] Step 2: Prepare a set of profiling fabric, and br...

Embodiment 2

[0043] In this embodiment, a high-strength and high-temperature-resistant composite material inlet is made. The diameter of the outlet end is 300 mm, and the inlet end is elliptical with a long circle of 150 mm and a short circle of 80 mm. The wall thickness of the air inlet is 4mm. The composite material is quartz fiber / polyarylene resin.

[0044] The forming steps of the air inlet are as follows:

[0045] Step 1: According to the overall thickness d of the product 总 and operating experience, the number of layers is designed to be 4, and the calculated d 单 = 1 mm. Profile offset d using 3D model 单 The distance of is to get the outline shape of each cloth layer. designed using Figure 4 For the 2.5D weaving method shown, the cloth layers from the inner surface to the outer surface are recorded as cloth layers 1, 2, 3, and 4 in sequence;

[0046] Step 2: Prepare a set of profiling fabric, and brush the release agent on the surface of the mold;

[0047] Step 3: Put cloth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com