Automatic batch coding machine for aluminum sectional material machining

A technology of aluminum profile processing and coding machine, which is applied in the direction of typewriters, transfer materials, conveyor objects, etc. It can solve the problems of irregular placement, skewed coding position, low efficiency, etc., and achieve simple disassembly and structure. , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

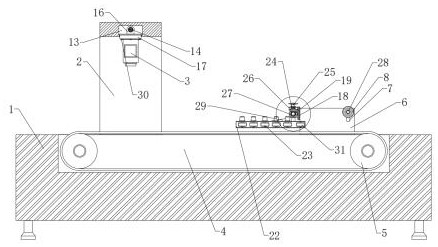

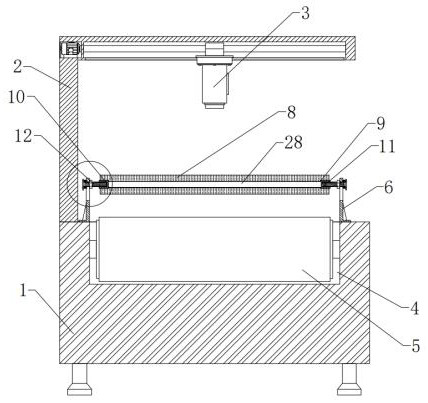

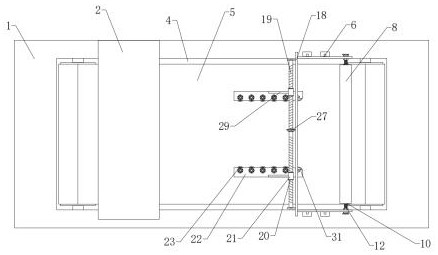

[0028] Embodiment: according to specification Figure 1-5 It can be seen that this case is an automatic batch coding machine for aluminum profile processing, including a main frame 1, a support frame 2, an adjustment mechanism, and a coding machine 3. A support frame 2 is provided on the top side of the main frame 1, and the adjustment mechanism is installed on the On the support frame 2, the coding machine 3 is installed on the adjustment mechanism. On the main frame 1 and below the coding machine 3, there is an automatic conveying and feeding mechanism. In the specific implementation process, the main frame 1 is used as the bottom support of the equipment. The support frame 2 is used as the supporting mechanism of the coding machine 3, and the displacement of the coding machine 3 is adjusted through the adjustment mechanism to match the needs of batch coding. The automatic feeding mechanism can automatically and neatly feed the coding machine 3, Ensure the accuracy of coding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com