Pilot-operated type electromagnetic valve

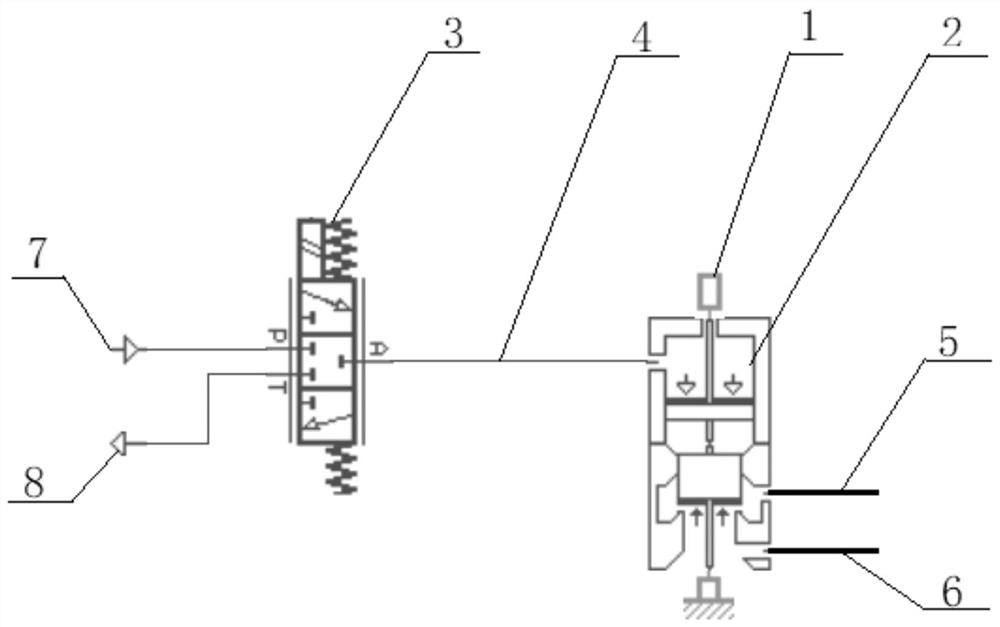

A pilot-operated solenoid valve and electromagnet technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as inability to adjust on-site, achieve environmental friendliness, simplify engine systems, and reduce weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

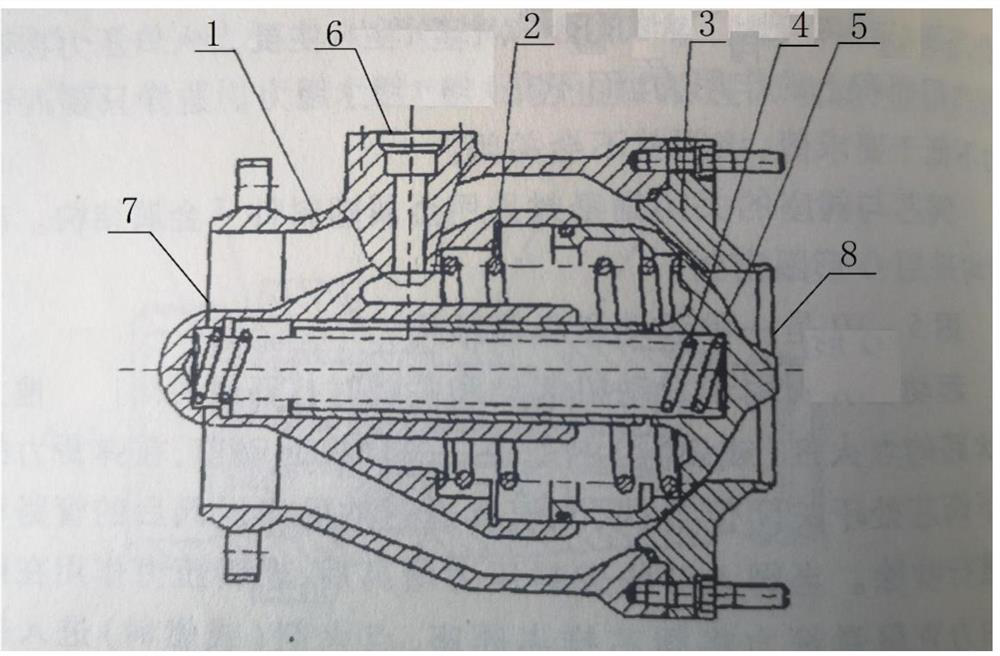

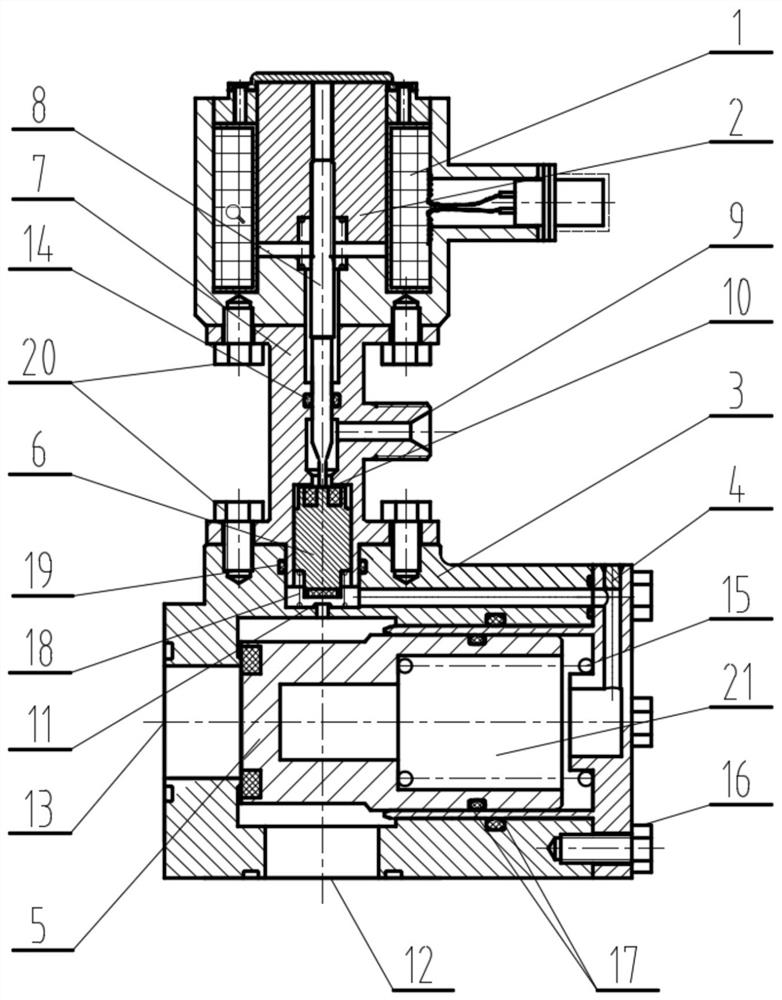

[0018] A pilot solenoid valve according to the present invention consists of an electromagnet assembly 1, an armature 2, a main valve body 3, an end cover 4, a main valve core 5, a pilot valve core 6, a pilot valve body 7, a top Rod 8, nozzle 9, upper sealing seat 10, lower sealing seat 11, valve inlet 12, valve outlet 13, springs 15, 18, O-rings 14, 17, 19, screws 16, 20, ejector rod 8 and armature 2 Through screw connection, the armature 2 is installed in the electromagnet assembly 1, the pilot valve core 6 is installed in the pilot valve body 7, the pilot valve body 7 is connected with the electromagnet assembly 1 and the main valve body 3 by screws, the main The valve core 5 is installed in the main valve body 3, the end cover 4 is connected with the main valve body 3 through screws, and a nozzle 9 is provided at the discharge port of the pilot valve body 7, the pilot valve body 7 and the ejector rod 8 and the main valve body 3 are sealed with O-rings 14 and 19;

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com