Efficient air preheater for fuel gas annealing furnace

A technology of air preheater and annealing furnace, which is applied in the direction of furnace, waste heat treatment, furnace components, etc. It can solve the problems of low preheating temperature, short equipment life, poor heat transfer effect of preheater, etc., and achieve high preheating temperature , Reduce equipment maintenance costs, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

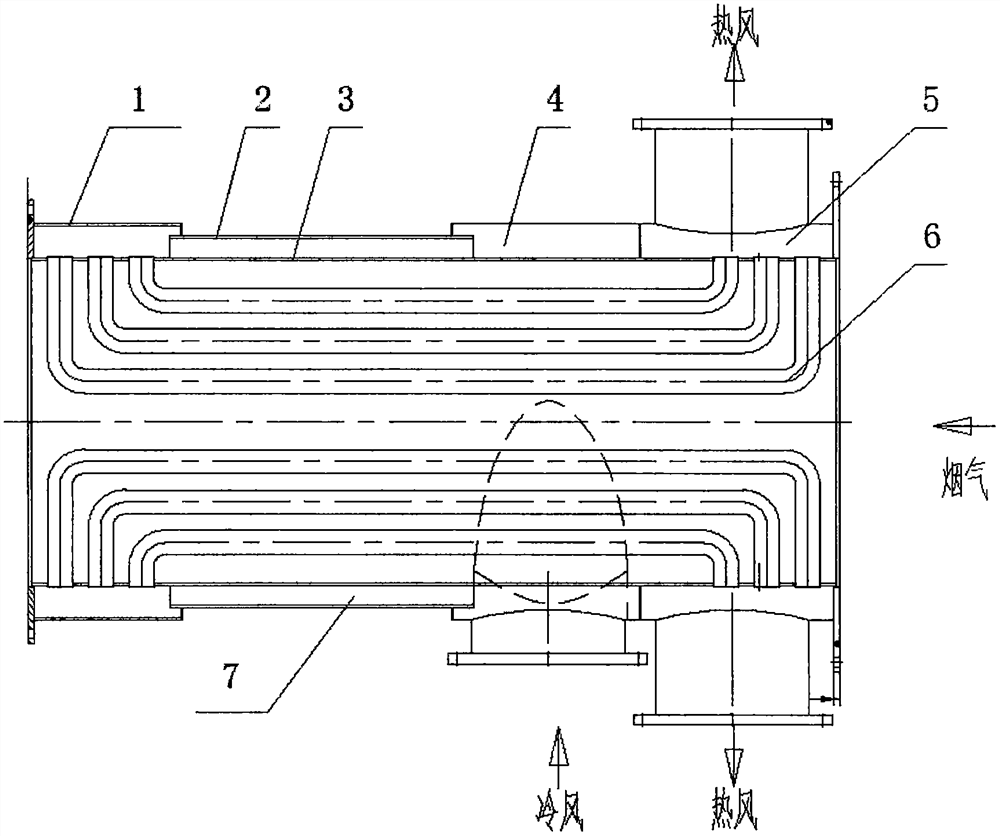

[0018] A high-efficiency air preheater for a gas annealing furnace, including an air preheater body, the air preheater body includes a wind box 1, and an inner cylinder 3 is provided on one side of the wind box 1, and the inner cylinder 3 is far away from the wind box 1 One end of the cylinder is provided with a cold air box 4, and the end of the cold air box 4 away from the inner tube 3 is provided with a hot air box 5.

[0019] Further speaking, an outer cylinder 2 is provided outside the inner cylinder 3 .

[0020] Furthermore, ribs 7 are provided between the inner cylinder 3 and the outer cylinder 2 .

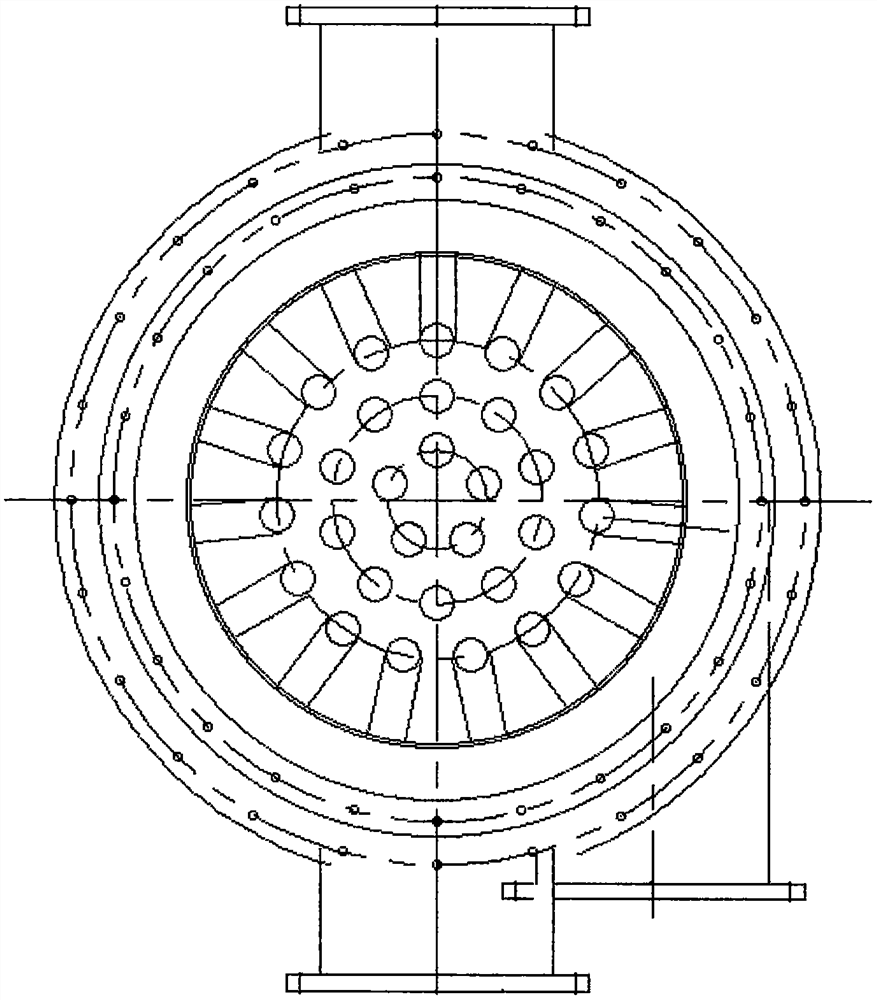

[0021] Furthermore, a convection tube bundle 6 is arranged inside the inner cylinder 3 .

[0022] Furthermore, the convection tube bundle 6 is pressed with screw marks before the tubes are bent, so as to increase the heat exchange area and imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com