Bidirectional fiber bragg grating double-variable sensor based on optical fiber sensing

A two-way optical fiber and optical fiber sensing technology, applied in the direction of instruments, measuring devices, measuring device casings, etc., can solve the problems of less research on temperature and strain bivariate sensors, low sensitivity of strain monitoring, and susceptibility to strong electromagnetic interference, etc., to achieve Ensure full contact and coordinated deformation, compact structure of the device, and strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

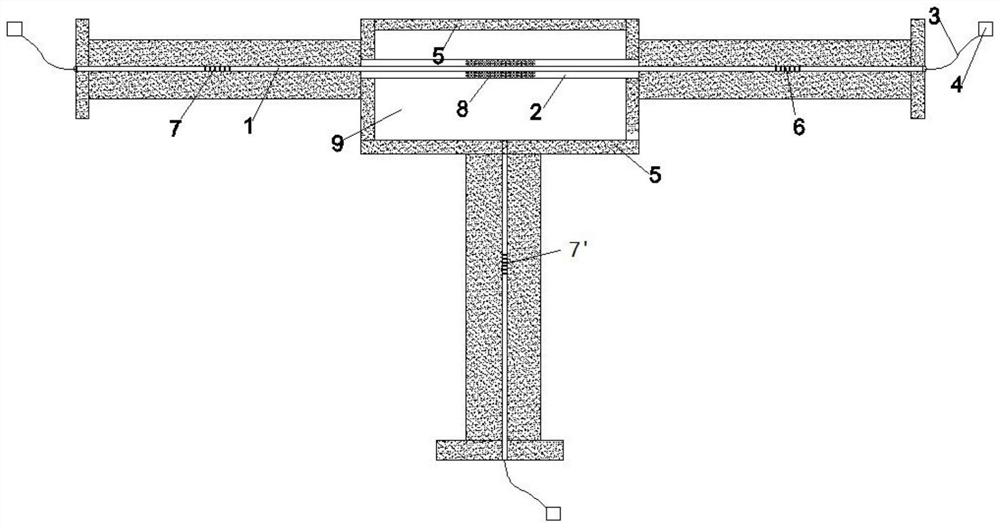

[0022] In this example, see figure 1 , a bidirectional fiber grating bivariate sensor based on optical fiber sensing, consisting of optical fiber 1, PVC optical fiber protection sleeve 2, optical cable 3, fiber grating demodulator 4, external packaging protection structure 5, temperature grating area 6, two strain Composed of grating areas 7, 7', optical fiber fusion splicing area 8, and device inner cavity 9; it is characterized in that one strain grating area 7 and temperature grating area 6 are packaged in a tube, while the other strain grating area 7' is embedded in a package In the inner cavity 9 of the device, the strain and temperature in two directions can be measured.

[0023] This embodiment is based on a bidirectional fiber grating bivariate sensor of optical fiber sensing, which can measure temperature and strain in two directions, and perform temperature compensation while measuring strain to obtain more accurate strain data; measure temperature and strain in two ...

Embodiment 2

[0025] This embodiment is basically the same as Embodiment 1, especially in that:

[0026] In this example, see figure 1 , the optical fiber 1 is an optical signal transmission area, and its tubular packaging section is connected with the strain grating area 7 and the temperature grating area 6 .

[0027] The strain grating area 7 and the temperature grating area 6 are connected by an optical fiber fusion splicing area 8 .

[0028] In this embodiment, the PVC optical fiber protection sleeve 2 has a diameter of 2mm.

[0029] The lengths of the strain grating region 7 and the temperature grating region 6 are not greater than 10mm.

[0030] The length of the optical fiber fusion zone 8 is not more than 60mm.

[0031] The optical fiber 1 is connected to the optical cable 3, and the change of the central wavelength of the grating area is obtained after the optical signal is analyzed by the fiber grating demodulator 4. The entire optical fiber 1 is protected by the PVC sleeve 2 e...

Embodiment 3

[0034] This embodiment is basically the same as the above-mentioned embodiment, and the special features are:

[0035] In this embodiment, the preparation method of the external packaging protection structure: the external protection structure is modeled by a 3D printing method, and then imported into a slicing software and printed to complete the external packaging protection structure. The invention directly embeds the bare fiber into the 3D printing packaging device, which ensures the complete contact and coordinated deformation of the grating measurement area and the device, and ensures the accuracy of measurement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com