Double-hydraulic-motor tree transplanting machine driving system

A drive system and hydraulic motor technology, applied in the direction of servo motors, servo motor components, fluid pressure actuators, etc., can solve the problems of increasing the weight of the mechanism, breaking the skin, occupying the internal diameter, etc., to increase the diameter and improve the integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

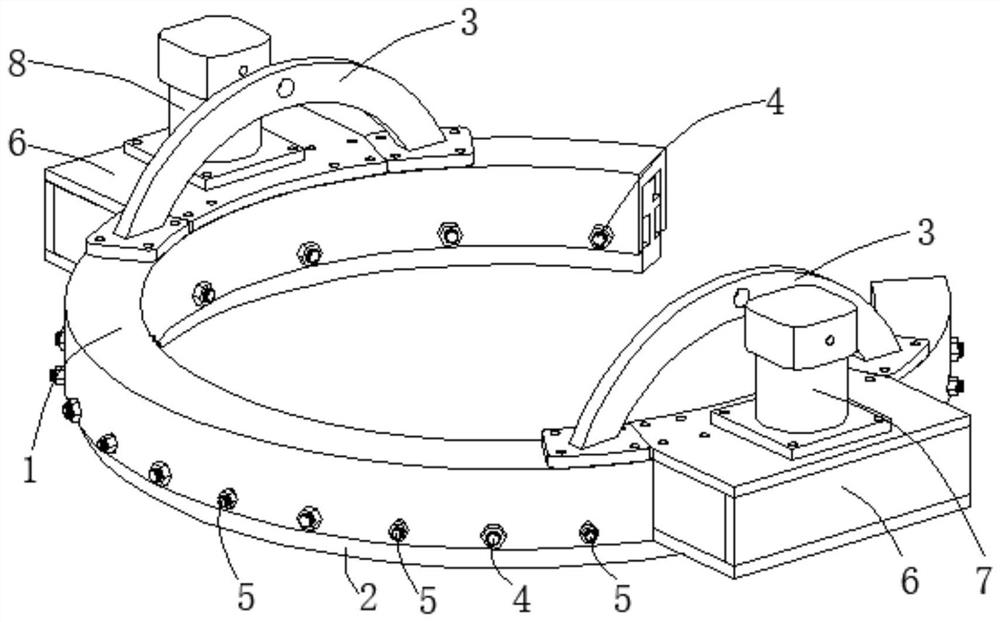

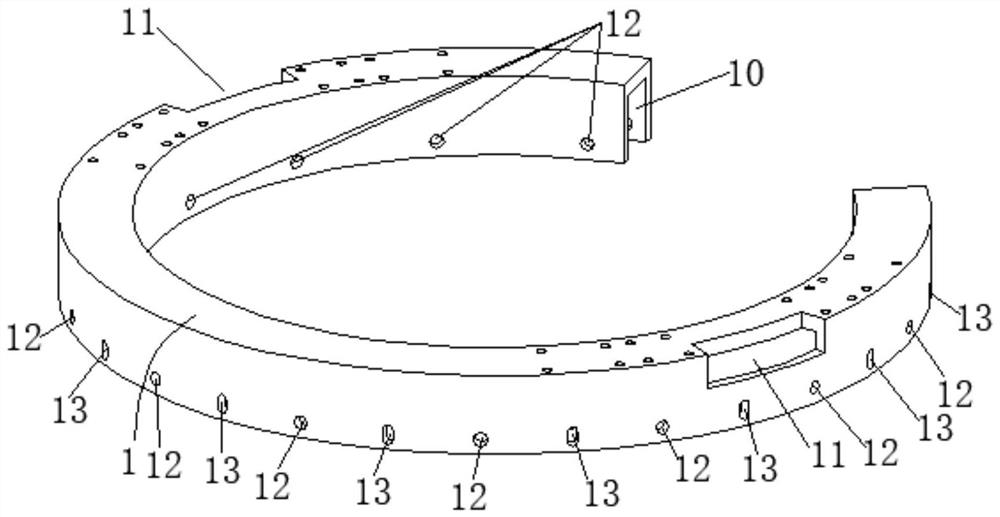

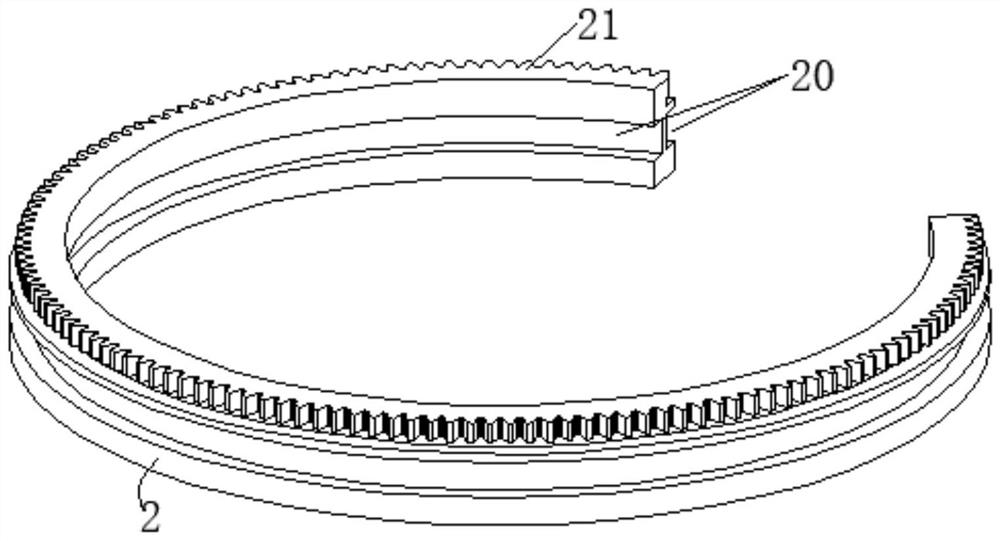

[0048] The dual hydraulic motor tree moving machine driving system of the present invention drives gear one 70 and gear two 80 to rotate through the first hydraulic motor 7 and the second hydraulic motor 8 at the same time, drives the outer ring gear 21 with the slewing ring 2 on the roller bearing 41 Under the support, rotate clockwise or counterclockwise 360° in the annular groove 10 in the slewing support upper cover 1. In the present invention, an outer ring gear 21 is arranged on the outer ring of the slewing ring 2, which avoids double gears occupying the inside of the slewing support upper cover 1. The diameter size increases the diameter of the tree moved by the tree mover.

Embodiment 2

[0050] The drive system of the tree moving machine with dual hydraulic motors of the present invention avoids the contact between the double gears and the bark, causing broken bark, and improves the integrity of the tree after excavation.

Embodiment 3

[0052] In the hydraulic system in the dual hydraulic motor tree moving machine drive system of the present invention, the hydraulic pump 93 extracts the hydraulic oil from the oil tank 90 and passes through the filter 91 to filter and the shut-off valve 92 reaches the one-way valve 94 from the oil outlet of the hydraulic pump 93 and Relief valve 96, when the left position of the reversing valve 95 is connected, the hydraulic oil enters the first hydraulic motor 7 and the second hydraulic motor 7 from the oil outlet port of the check valve 94 through the P port and B port of the reversing valve 95. The oil outlet of the motor 8 enters, drives the first hydraulic motor 7 and the second hydraulic motor 8 to rotate forward, and then the hydraulic oil flows out from the oil inlet of the first hydraulic motor 7 and the second hydraulic motor 8, and then flows through the reversing valve 95 The A port and T port of the reversing valve 95 enter the oil tank 90; when the right position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com