A kind of forging method and application of low direction sensitive 7xxx series aluminum alloy

An aluminum alloy, sensitive technology, applied in the direction of metal processing equipment, etc., can solve the problems of insufficient rheological properties in the "dead zone", reduce the direction sensitivity of forgings, and insufficient recrystallization process, etc., and achieve uniform microstructure and isotropic properties of forgings , No reduction in surface performance, and the effect of reducing direction sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

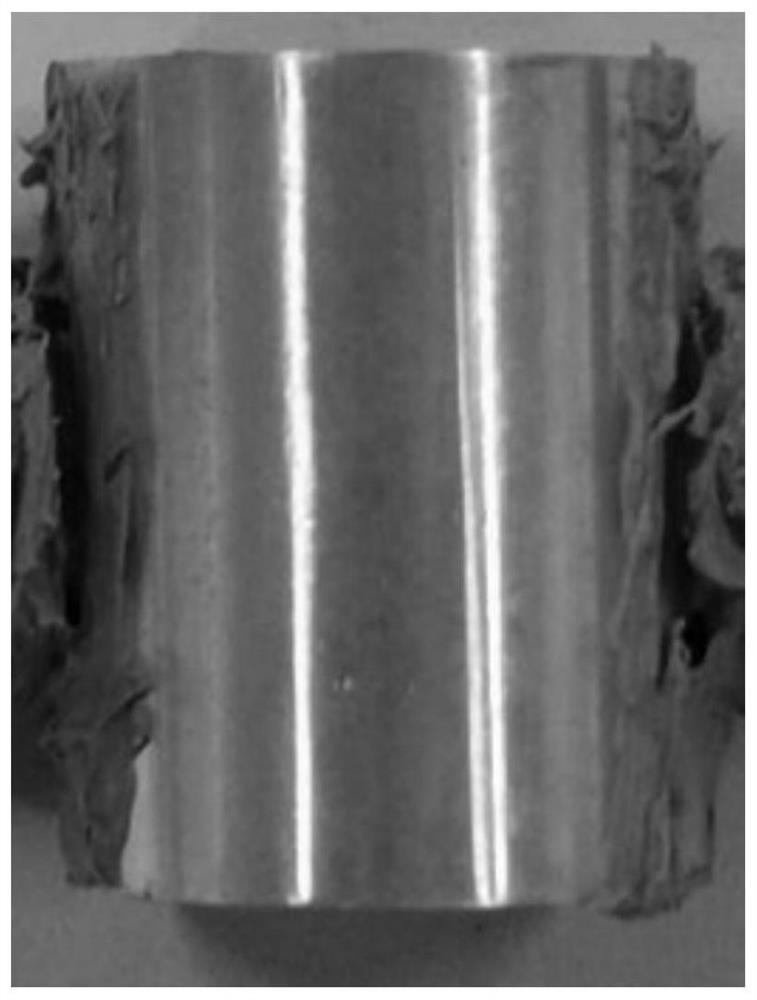

Image

Examples

Embodiment 1

[0050]Example 1: The blank is 7085 aluminum alloy with 150×200×200 mm. The blank was heated to 460°C, kept for 2 hours, then placed at 340°C, kept for 2 hours, and pre-forged at 340°C for multiple passes, from 200mm to 130mm; then the forgings were heated to 460°C and kept for 2 hours. Recrystallized but will not grow up, and it takes longer to keep warm when growing up), hot forging at 460 ° C, forging from 130 mm to 90 mm, during the hot forging process, the upper and lower surfaces are sprayed with coolant until the surface temperature reaches 380 ° C, and the forging is completed. Air-cooled.

Embodiment 2

[0052] Example 2: The blank is 7A85 aluminum alloy with 150×200×200 mm. The blank was heated to 460°C, kept for 2 hours, then placed at 340°C, kept for 2 hours, and pre-forged at 340°C for multiple passes, from 200mm to 130mm; then the forgings were heated to 460°C, kept for 2 hours, and hot forged at 460°C. , Forging from 130mm to 90mm, during the hot forging process, the upper and lower surfaces are sprayed with coolant until the surface temperature reaches 380 °C, and air cooling is performed after forging.

Embodiment 3

[0054] Example 3: The blank is 7085 aluminum alloy with 150×200×200 mm. The blank was heated to 460°C, kept for 2 hours, then placed at 340°C, kept for 2 hours, and pre-forged at 340°C for multiple passes, from 200mm to 130mm; then the forgings were heated to 460°C, kept for 2 hours, and hot forged at 460°C. , Forging from 130mm to 90mm, during the hot forging process, the upper and lower surfaces are sprayed with coolant until the surface temperature reaches 380 °C, and air cooling is performed after forging.

[0055] The size of the final plate after the treatment of the comparative example and the example is 330×200×90mm. The material prepared in the comparative example and the example is heat-treated to T6 or T74 state. Example 1, Comparative Example 2, and Example 2 all adopt the T6 aging system and age at 120°C / 34h; Comparative Example 3 and Example 3 all adopt the T74 aging system, and perform two-stage aging at 120°C / 7h+160°C / 10h . Table 1 shows the comparison of pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com