Intelligent ultrahigh pressure hydraulic pump based on Internet

A technology of ultra-high pressure and hydraulic pumps, which is applied to components, pumps, and pump controls of pumping devices for elastic fluids. It can solve problems such as difficult structural design, intricate pipeline valves, and large overall volume, and achieve compactness. The effect of light output pressure, small size and light weight, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The technical principles and structures of the intelligent ultra-high pressure hydraulic pump of the present invention will be further described below with reference to the drawings.

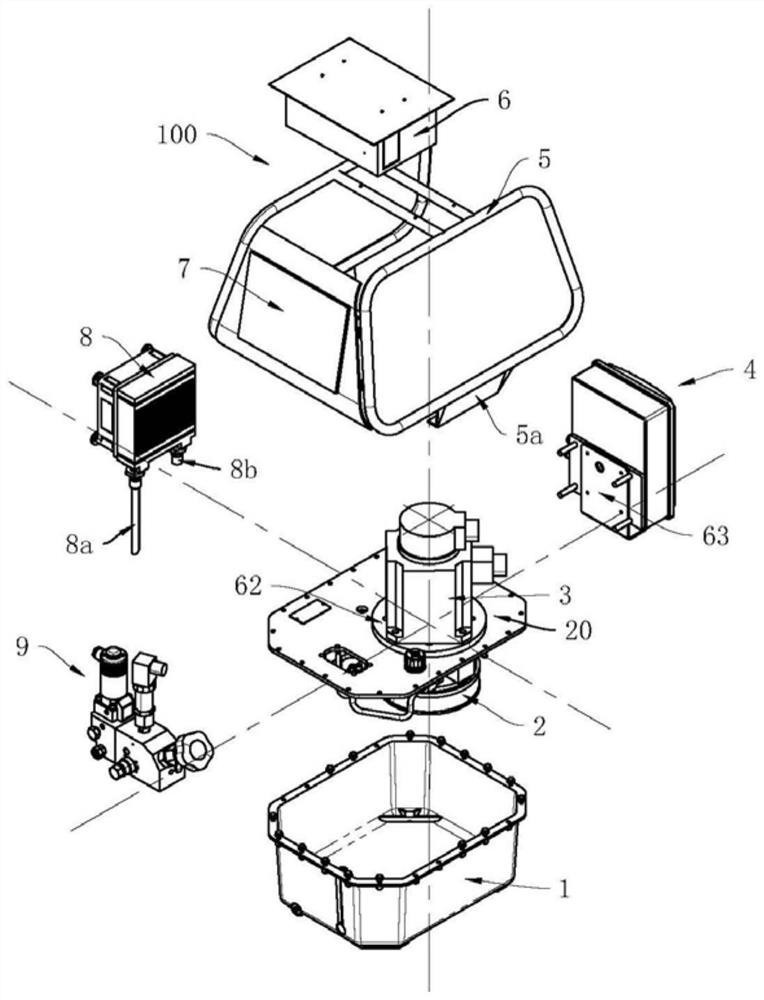

[0075] like Figure 1-4As shown, the intelligent ultra-high pressure hydraulic pump of the present invention includes a fuel tank module 1, a servo motor 3, a wind cooler 8, a bracket module 100, a pump body module 2, a valve module 9, and a large portion of the electric control box 4.

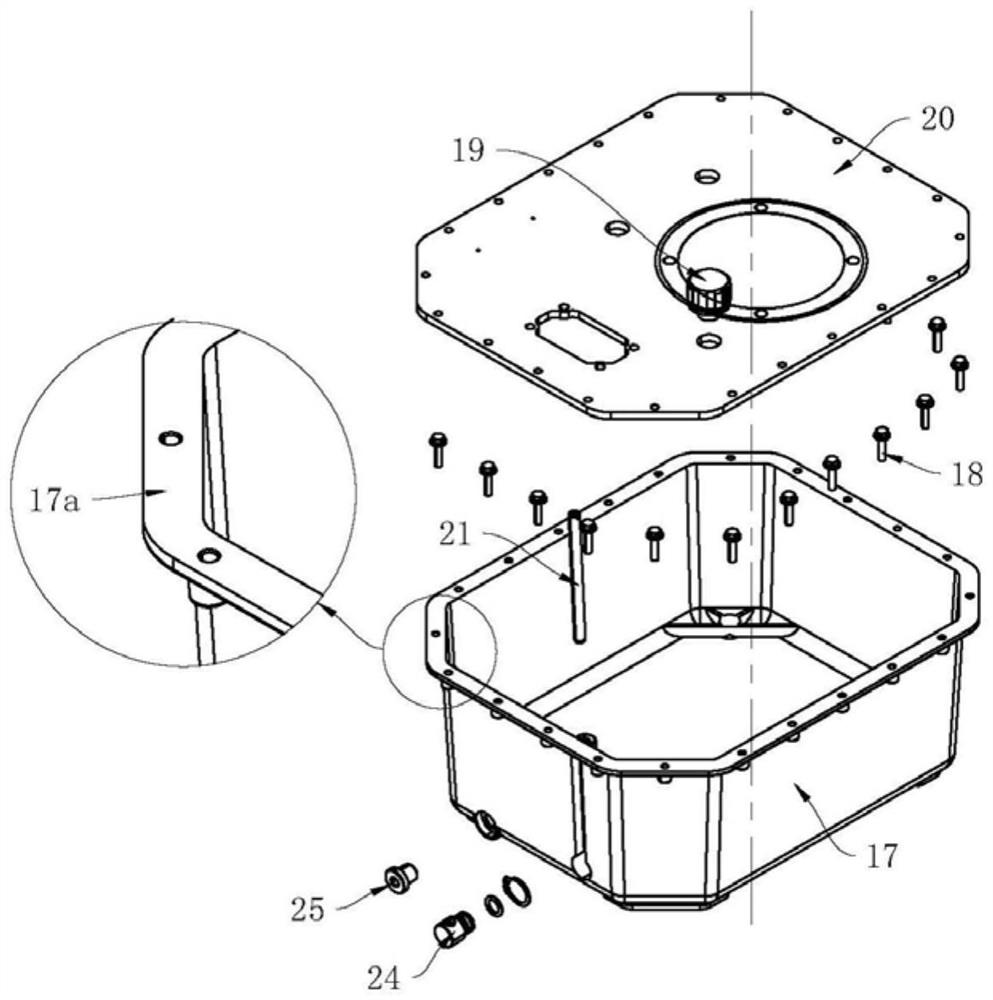

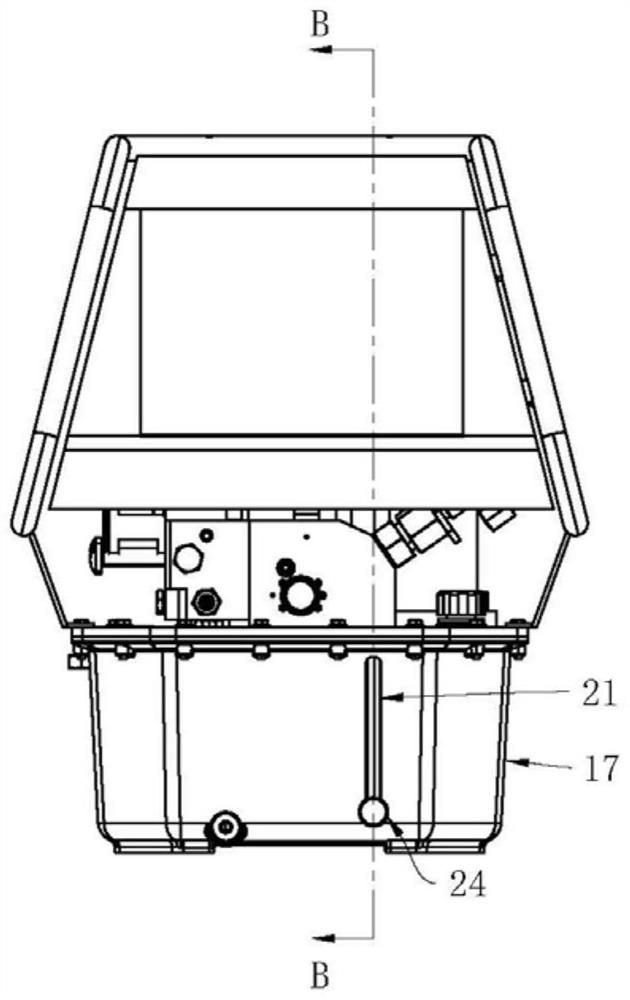

[0076] The fuel tank module 1 is the main support of the intelligent ultra high pressure hydraulic pump. The fuel tank module 1 consists of a fuel tank cover 20, a tank 17, a oil label 21, a oil label fixing head 24, a drain push 25, and the like. The tank 17 is a groove structure, and the flange 17 is formed over the fuel tank 17, the fuel tank cover 20 is a flat-panel structure, the fuel tank cover 20 edge contour and the fuel tank 17 overwards the flange edge of the fuel tank 17 17A is fixedly attached to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com