Optical fiber laser cutting machine

A laser cutting machine, fiber laser technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of metal block falling off, metal block falling on the surface of the support frame, time waste, etc., and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

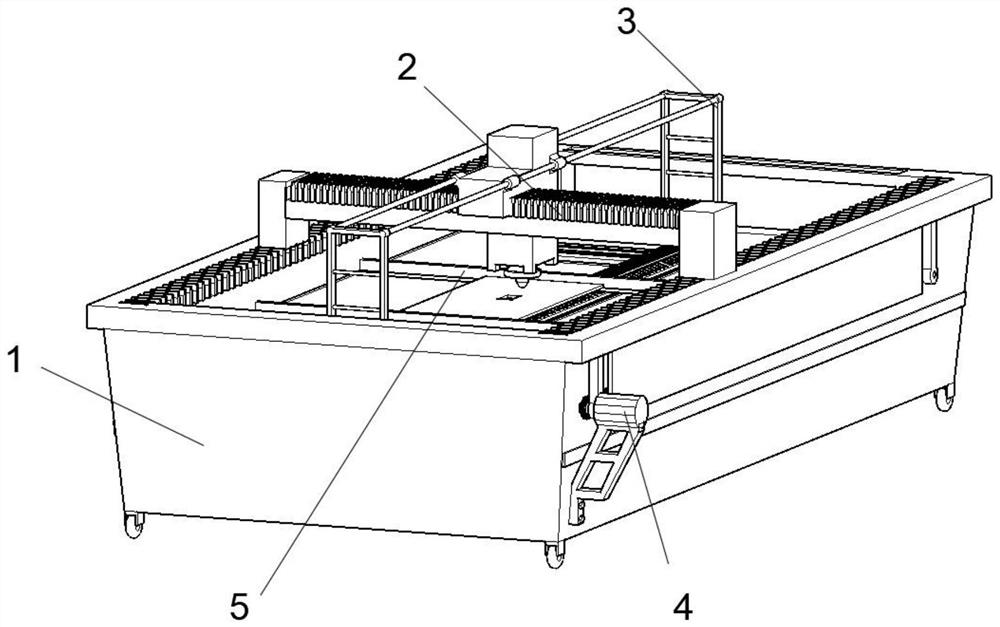

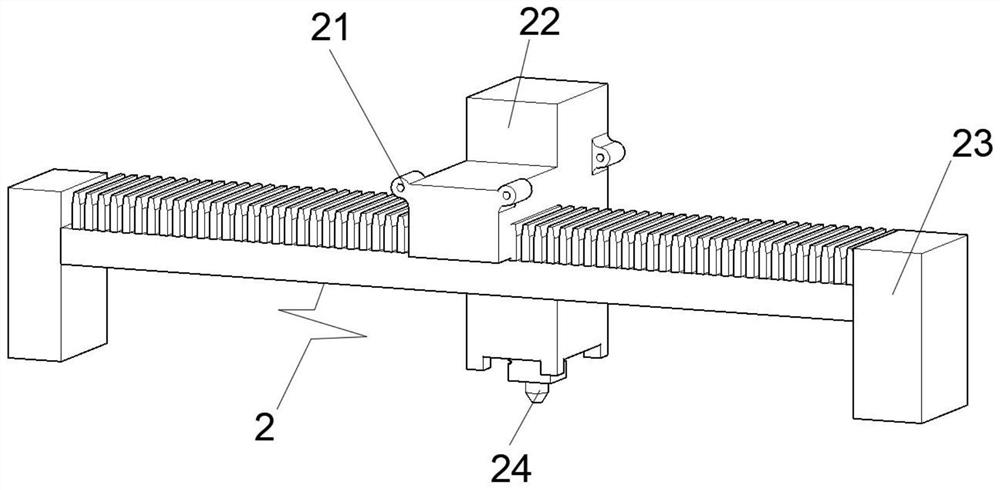

[0031] see Figure 1-6 , an embodiment provided by the present invention: a fiber laser cutting machine, including a laser cutting machine 1, a fiber laser cutting device 2, a conveying device 3, a driving device 4 and a clamping plate 5, and the fiber laser cutting device 2 is slidably installed on Inside the top end of the laser cutting machine 1, the conveying device 3 is slidably installed inside the laser cutting machine 1 and on the outer surface of the fiber laser cutting device 2, and the driving device 4 is fixedly installed on the inner center peripheral edge of the laser cutting machine 1, and the clamping plate 5 is slidably installed inside the laser cutting machine 1;

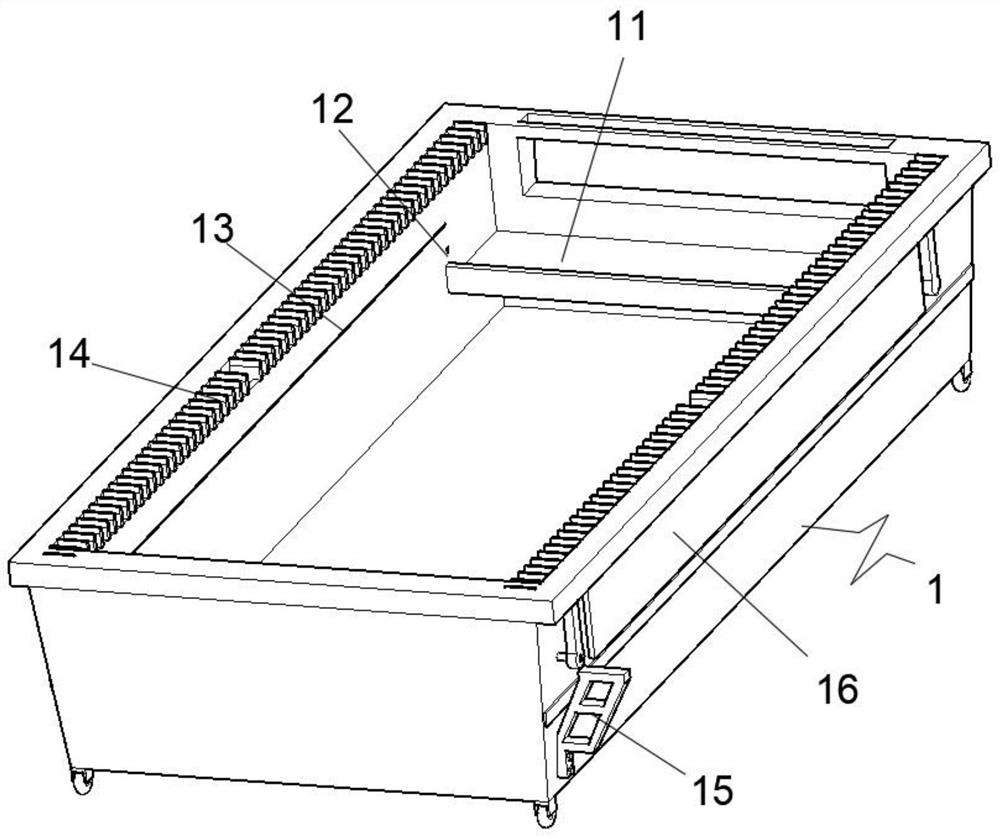

[0032] The interior of the laser cutting machine 1 includes a collection table 11, a limit shaft hole 12, a limit slideway 13, a dust-proof folding cloth 14, a support frame 15 and a protective side plate 16. The limit slideway 13 is set symmetrically on the laser cutting machine 1. In the center...

Embodiment 2

[0041] On the basis of Example 1, such as Figure 7-8 As shown, the central edge of the bottom surface of the cutter 22 is slidably installed with an auxiliary blanking device 25. The interior of the auxiliary blanking device 25 includes a plug-in post 251, a hoop 252, a buffer spring 253 and a rubber block 254, and the plug-in post 251 is evenly welded. On the outer surface of the hoop 252 , a rubber block 254 is fixedly connected to the center of the bottom surface of the insertion post 251 , and the buffer spring 253 is sleeved on the outer surface of the insertion post 251 .

[0042] When this embodiment is implemented, after the laser cutting head 24 cuts the metal plate, it will descend downwards, and the laser cutting head 24 will drive the auxiliary blanking device 25 to descend at the same time, because the bottom end of the auxiliary blanking device 25 is lower than the laser The bottom of the cutting head 24, so when the laser cutting head 24 descends, it will drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com