Mirror surface polishing equipment for electrical product

A technology for electrical products and equipment, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc. It can solve the problems of low precision, no guiding function, and low stability, so as to improve work efficiency and increase stability. Sex, increase the effect of adsorption strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

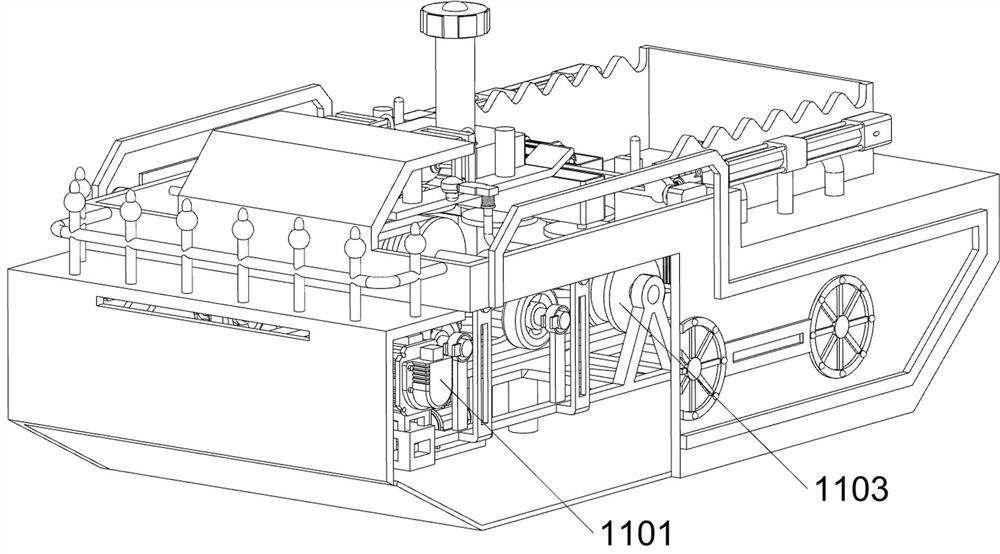

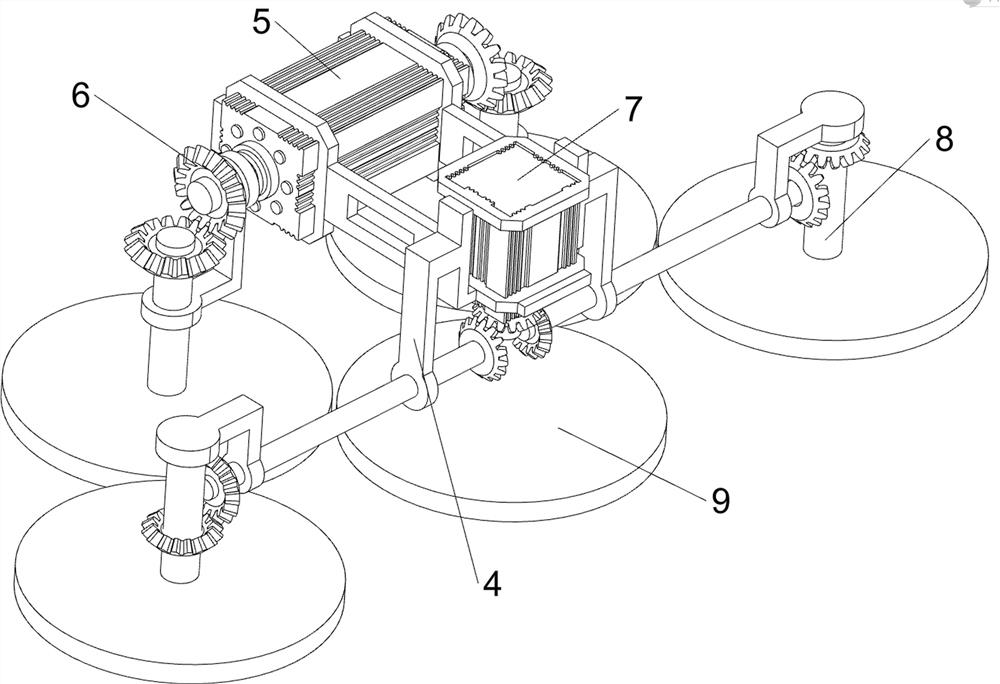

[0039] A mirror polishing equipment for electrical products, such as figure 1 , figure 2 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, it includes a box body 1, a start key 2, a housing 4, a double-axis motor 5, a bevel gear 6, a servo motor 7, a first rotating shaft 8, a grinding wheel 9, a drive assembly 10, a rotation assembly 11 and a guide assembly 12 , the start key 2 is installed on the right front side of the upper part of the box body 1, the drive assembly 10 is arranged on the upper side of the inside of the box body 1, and the drive assembly 10 is slidably provided with a casing 4 connected to it, and a double shaft is installed on the left rear side of the casing 4. Motor 5, a servo motor 7 is installed in the middle of the right side of the inside of the housing 4, and the front and rear sides of the housing 4 are rotated to be provided with a rotating rod, and the left and right sides of the housing 4 a...

Embodiment 2

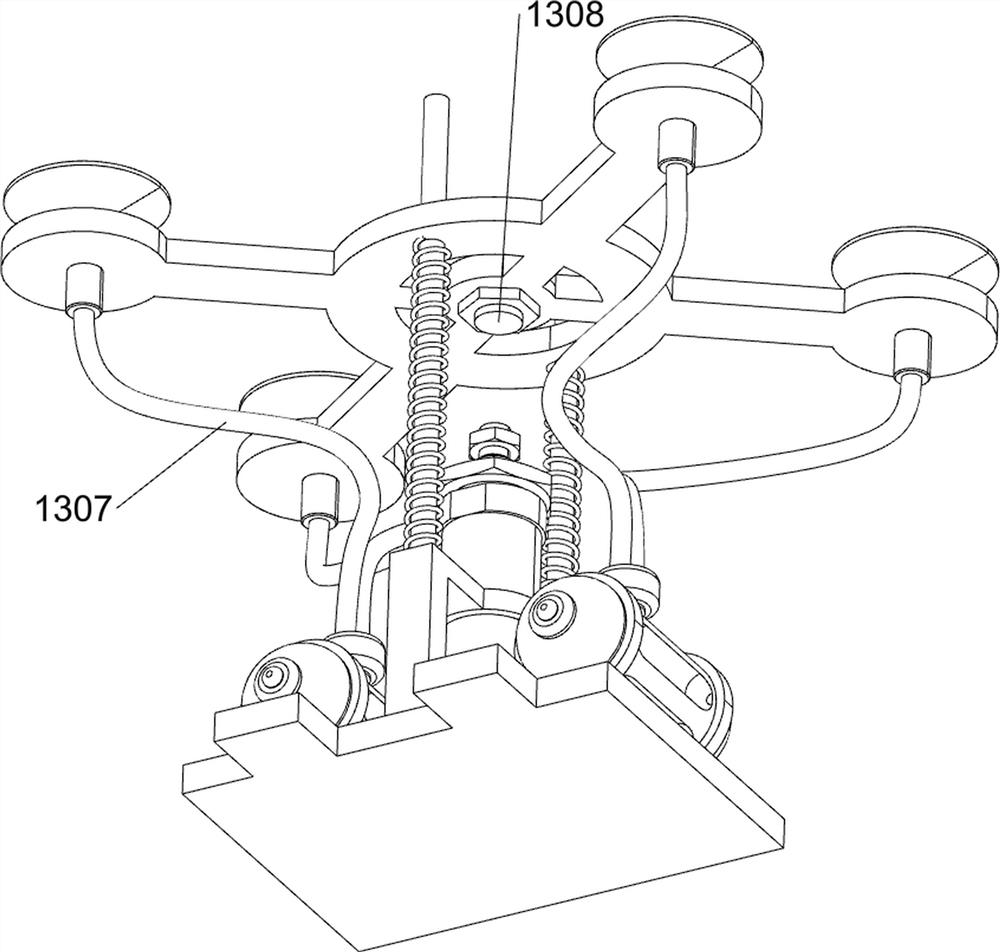

[0045] On the basis of Example 1, such as image 3 , Figure 4 , Figure 5 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 and Figure 18 As shown, the adsorption assembly 13 is also included, and the adsorption assembly 13 includes a photoelectric sensor 1301, a second electric push rod 1302, a first connecting plate 1303, a suction cup 1304, a second spring 1305, a first air pump 1306, a first air pipe 1307 and A pressure sensor 1308, a photoelectric sensor 1301 is arranged symmetrically in the middle of the upper side inside the box body 1, a second electric push rod 1302 is installed between the lower right side inside the box body 1 and the support plate, and a sliding connection is made in the middle right side of the support plate. The first connecting plate 1303, the telescopic rod of the second electric push rod 1302 cooperates with the first connecting plate 1303, the top of the first connecting plate 1303 is evenly spaced with four suction cu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap