Oil field fracturing flow-back fluid sewage purification treatment device

A sewage purification and oil field fracturing technology, which is applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc., can solve the problems of reduced filtering effect, filter clogging, high concentration, etc., and achieve improvement Efficiency and effect, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

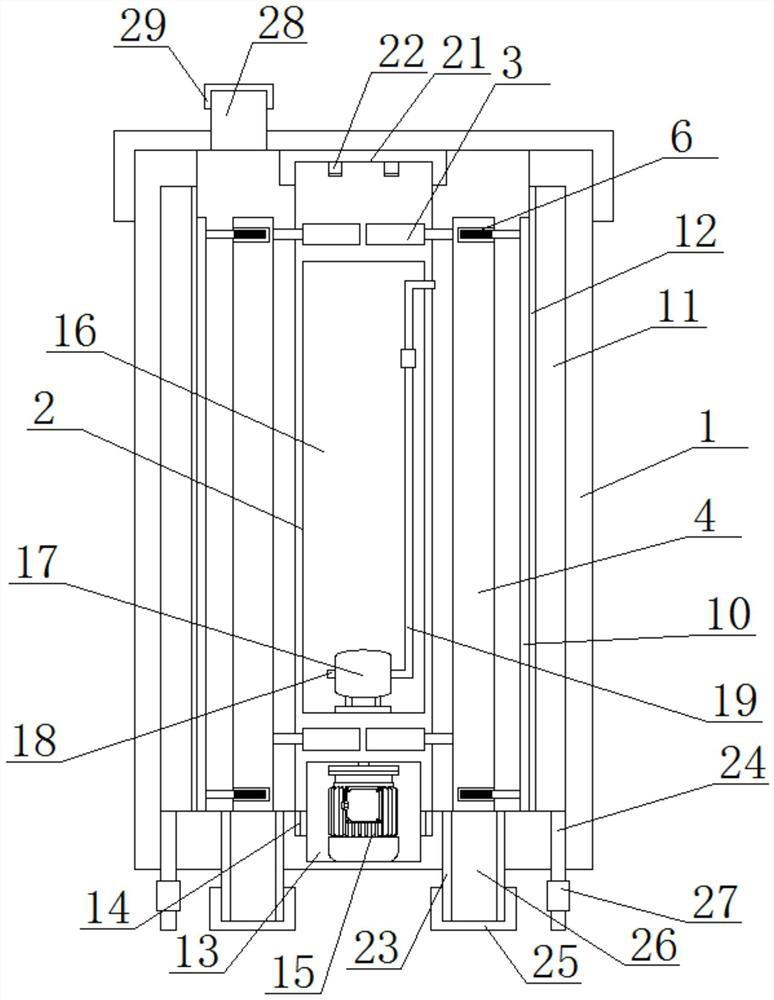

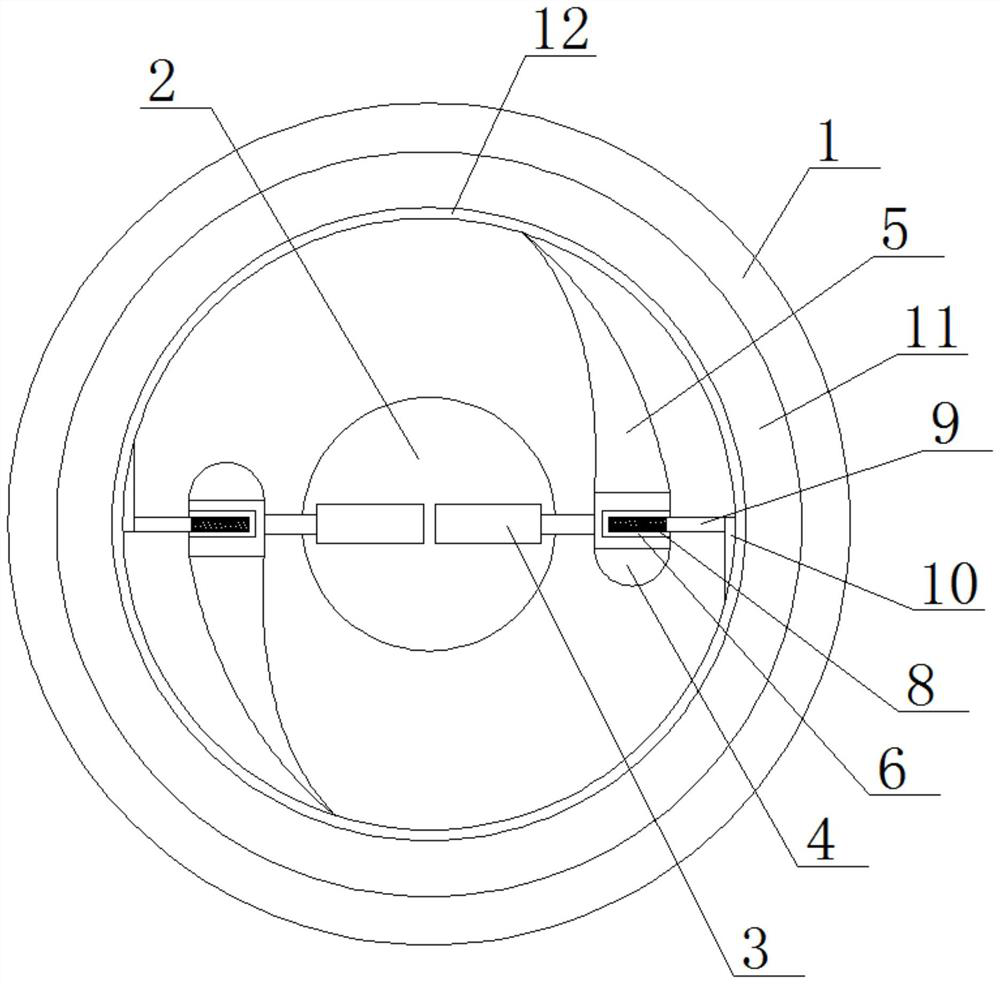

[0021] In order to make the techniques, creative features, objective and efficacy of the present invention, and the embodiments are further illustrated in connection with the specific embodiments.

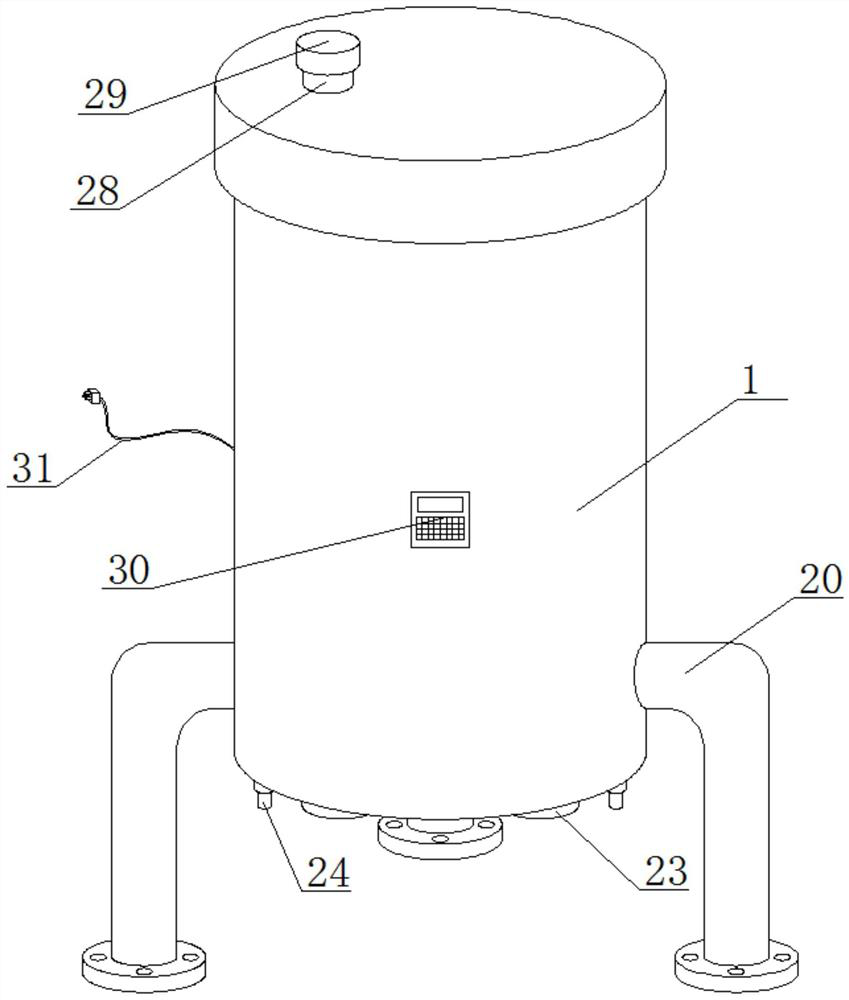

[0022] See Figure 1 to 5 The present invention provides a technical solution: an oil field fracturing returning drain sewage purification treatment device, including processing tank 1 and a central rotation shaft 2, and both sides of the central rotating shaft 2 are fixedly inlaid with electric push rod 3, said A round-side fixture 4 is fixedly mounted on the output shaft of the electric push rod 3, and the rear side of the rounded fixing seat 4 is fixedly mounted, and an arcuate elastic rubber pressure plate 5 is fixed, and one side of the rounded fixing seat 4 is fixed inlaid. The fixing rod 6 is opened at one end of the fixing rod 6, and the spring groove 7 is fixedly connected to the inner side wall of the opening, and one end of the telescoping rod 9 passes through the opening end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com