Concrete corrosion inhibitor and preparation method thereof

An anti-corrosion agent and anti-oxidant technology, applied in the direction of anti-corrosion coatings, coatings, polyether coatings, etc., can solve the problems of insufficient durability protection, high self-shrinkage and brittleness of concrete, and achieve compact structure and good compactness , strong hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A concrete anticorrosion agent is prepared through the following steps:

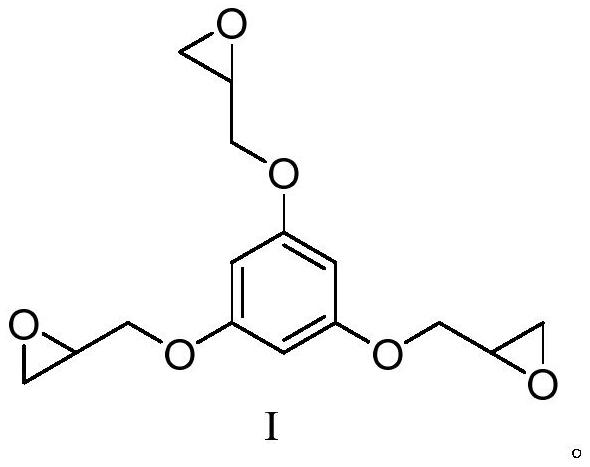

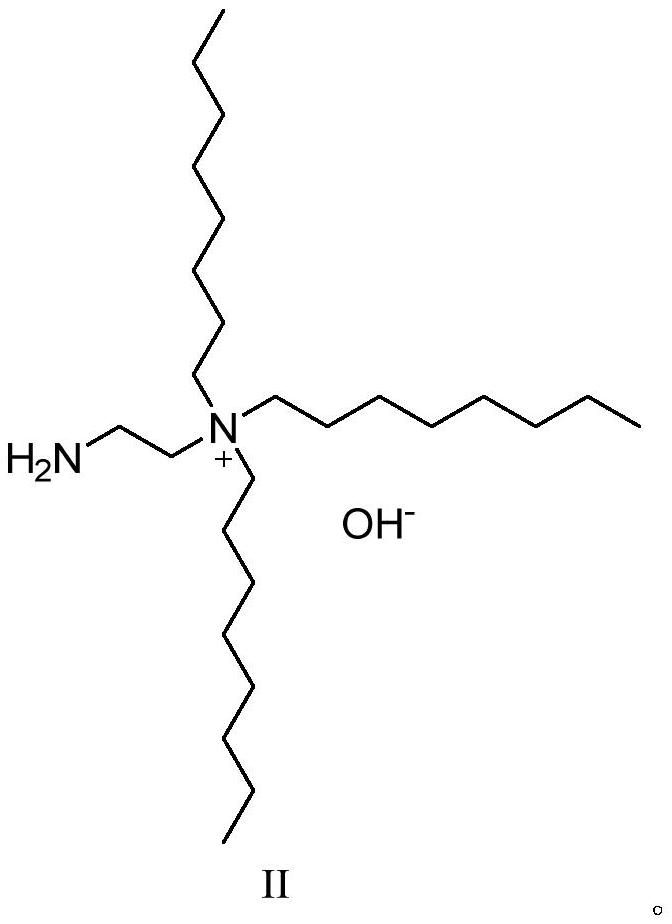

[0043] S1: Mix 40 parts of pyroglucinol triglycidyl ether and 40 parts of trioctylamine ethyl ammonium hydroxide, heat to 80°C, and react for 2 hours;

[0044] S2: After the reaction of S1 is completed, add 100 parts of trifunctional polyether polyol (Puranol G 305), heat to 100°C, and continue the reaction for 4 hours;

[0045] S3: Add 10 parts of m-xylylenediamine to the mixture obtained after the reaction in S2 to continue the reaction for 1 hour, and lower the temperature to 25° C. to obtain the anticorrosion agent.

Embodiment 2

[0047] A concrete anticorrosion agent is prepared through the following steps:

[0048] S1: Mix 30 parts of pyroglucinol triglycidyl ether and 40 parts of trioctylamine ethyl ammonium hydroxide, heat to 60°C, and react for 3 hours;

[0049] S2: After the reaction of S1 is completed, add 80 parts of trifunctional polyether polyol (Puranol G 307), heat to 90°C, and continue the reaction for 6 hours;

[0050] S3: Add 20 parts of m-xylylenediamine, 0.3 parts of polydimethylsiloxane and 2 parts of chemnox 168 to the mixture obtained after the reaction of S2, continue the reaction for 2 hours, and lower the temperature to 25° C. to obtain the anti-corrosion agent.

Embodiment 3

[0052]A concrete anticorrosion agent is prepared through the following steps:

[0053] S1: Mix 40 parts of pyroglucinol triglycidyl ether and 30 parts of trioctylamine ethyl ammonium hydroxide, heat to 60°C, and react for 3 hours;

[0054] S2: After the reaction of S1 is completed, add 80 parts of trifunctional polyether polyol (Puranol G 306), heat to 110°C, and continue the reaction for 4 hours;

[0055] S3: Add 15 parts of m-xylylenediamine to the mixture obtained after the reaction in S2 to continue the reaction for 1 hour, and lower the temperature to 25° C. to obtain the anticorrosion agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com