Water-based peelable single-color-change irreversible temperature indicating coating and preparation method thereof

A temperature-indicating paint and color-changing pigment technology, applied in the field of color-changing paint, can solve the problems of low temperature measurement accuracy, easy residual environment, and pollution of temperature-indicating paint, and achieve the effects of easy peeling and removal, fast color changing speed, and high temperature measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

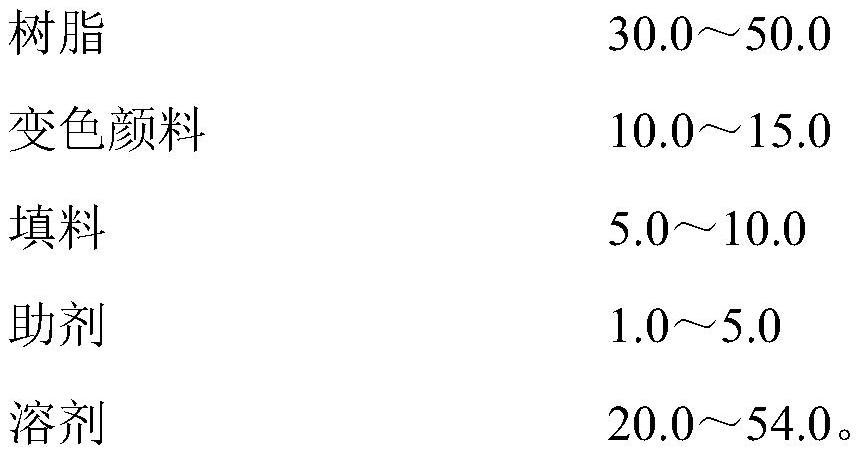

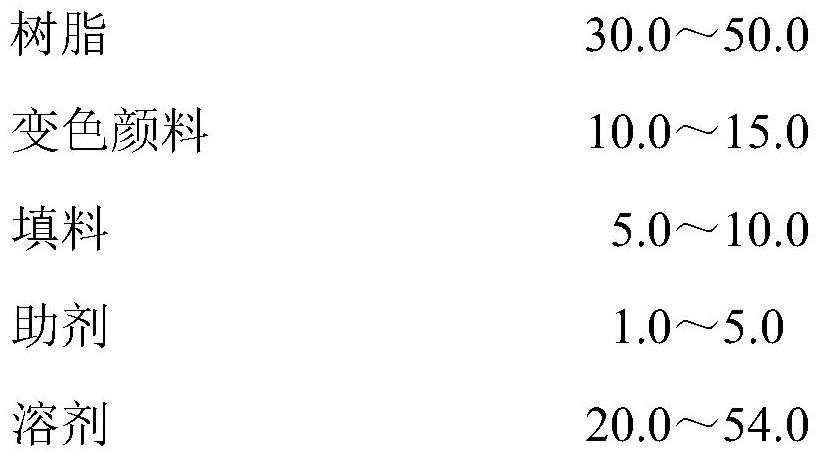

Method used

Image

Examples

Embodiment 1

[0022] Accurately weigh 54.0g of deionized water and 1.0g of byk190, use high-speed stirring, and stir until byk190 is completely dissolved. Control the stirring speed at 200-300r / min, add 5.0g talcum powder and 10.0g lead stearate in sequence, and continue stirring until the system is uniform without agglomeration, and the slurry is prepared. The prepared slurry was sent to a sand mill for grinding and dispersion, and the measured fineness was 30 μm. Then, add 30.0 g of water-based SBS emulsion, use high-speed stirring, control the stirring speed at 200-300 r / min, and stir for 30 minutes to disperse the components evenly. Finally, filter the dispersed paint solution with a 120-mesh sieve and fill it into a tank to obtain a water-based peelable temperature-indicating paint. It is recorded as coating 1, and the technical specifications are shown in Table 1.

Embodiment 2

[0024] Accurately weigh 42.0g of deionized water, 4.0g of byk192, and 1.0g of FA179 using high-speed stirring until byk192 and FA179 are completely dissolved. Control the stirring speed at 200-300r / min, add 6.0g of silicon dioxide and 12.0g of cadmium stearate in sequence, and continue to stir until the system is uniform without agglomeration, and the slurry is prepared. The prepared slurry was sent to a sand mill for grinding and dispersion, and the measured fineness was 30 μm. Then, add 35.0 g of water-based peelable acrylic emulsion, use high-speed stirring, control the stirring speed at 200-300 r / min, and stir for 30 minutes to disperse the components evenly. Finally, filter the dispersed paint solution with a 120-mesh sieve and fill it into a tank to obtain a water-based peelable temperature-indicating paint. It is recorded as coating 2, and the technical specifications are shown in Table 1.

Embodiment 3

[0026] Accurately weigh 36.0g deionized water, 1.0gbyk191, 1.0gFA179 using high-speed stirring, stir until byk191 and FA179 are completely dissolved. Control the stirring speed at 200-300r / min, add 8.0g of quartz powder and 14.0g of zinc stearate in sequence, and continue to stir until the system is uniform without agglomeration, that is, the slurry is prepared. The prepared slurry was sent to a sand mill for grinding and dispersion, and the measured fineness was 30 μm. Then, add 40.0 g of water-based peelable PU emulsion, use high-speed stirring, control the stirring speed at 200-300 r / min, and stir for 50 minutes to disperse the components evenly. Finally, filter the dispersed paint solution with a 120-mesh sieve and fill it into a tank to obtain a water-based peelable temperature-indicating paint. It is recorded as coating 3, and the technical specifications are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com