Corrosion-resistant insulating mask and manufacturing method thereof

A manufacturing method and mask technology, applied in the field of masks, can solve the problems of mask falling off, affecting the efficiency of netting, and prone to corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

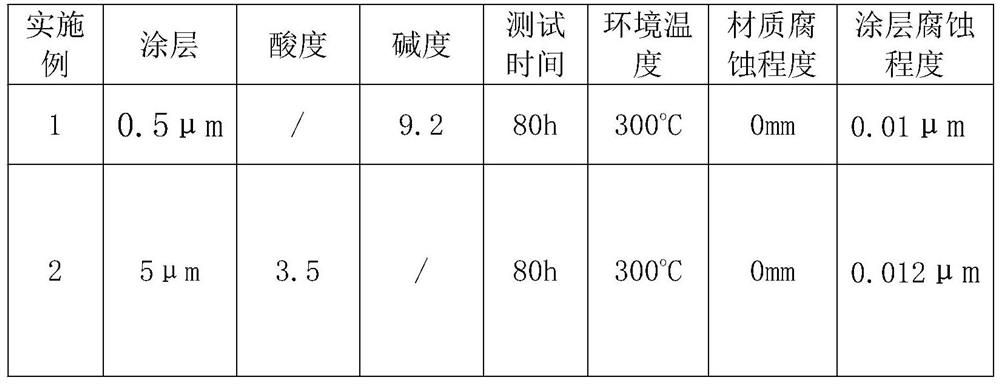

Embodiment 1

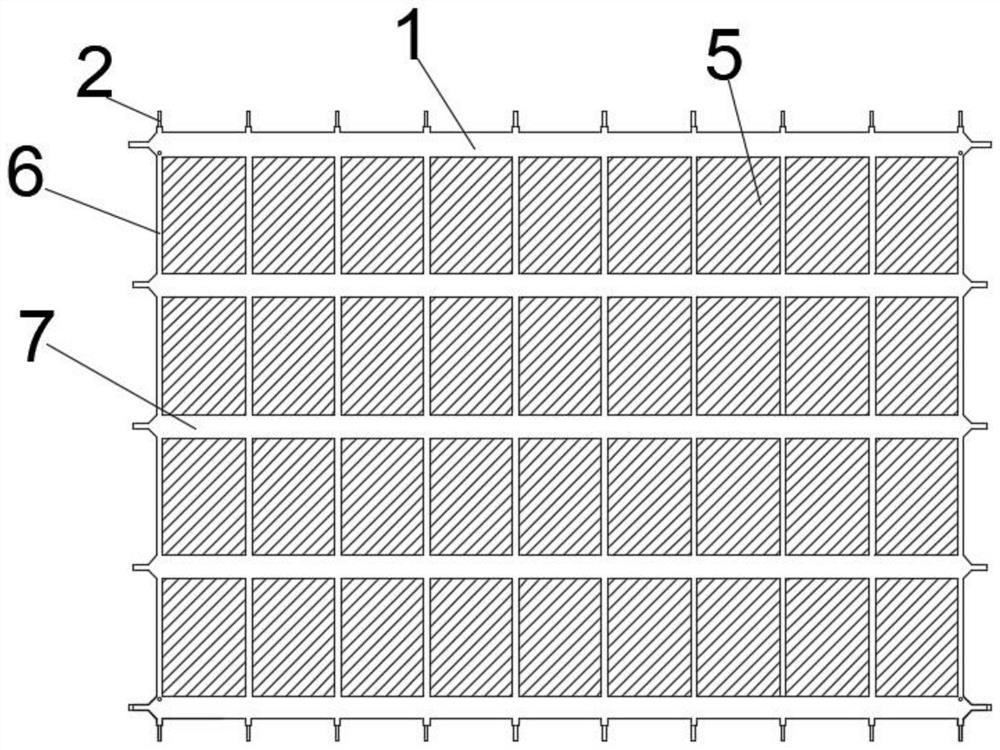

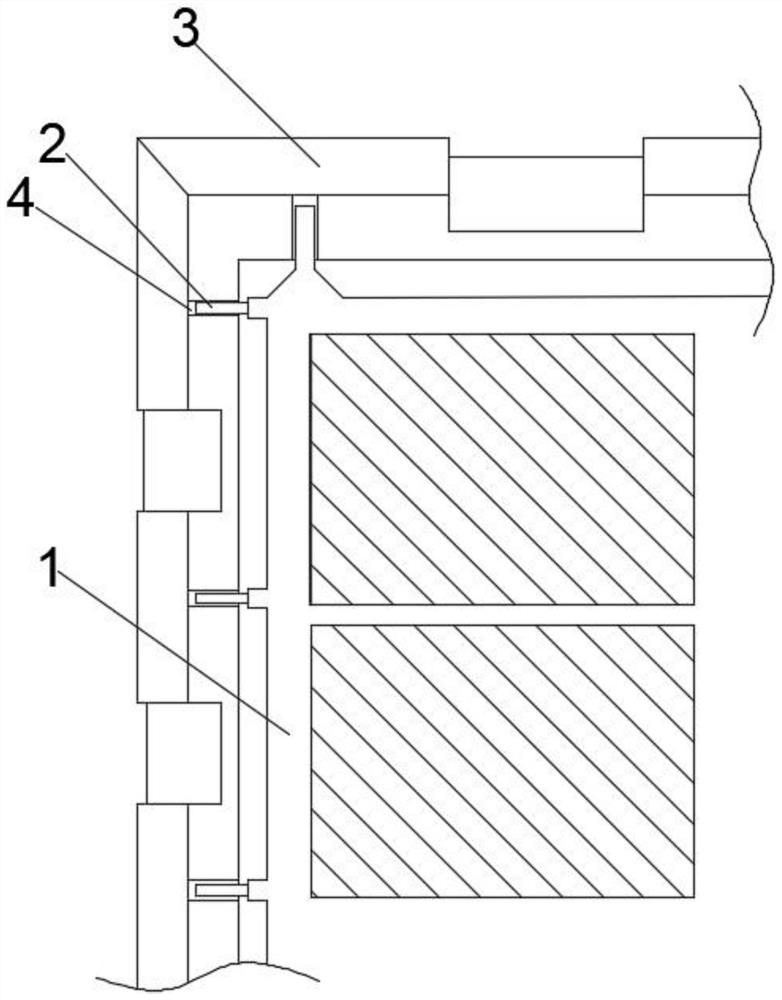

[0024] A corrosion-resistant insulating mask, including a mask 1 and a mask metal frame 3, the mask 1 includes a plurality of horizontal bars 7 and a plurality of vertical bars 6; between the horizontal bars 7 and the vertical bars 6 is a positive Cross-relationships and horizontal bars 7 and vertical bars 6 intersect to form a plurality of vapor deposition areas 5, each horizontal bar 7 and each vertical bar 6 are provided with axons 2 at both ends, and the mask plate metal frame 3 is provided with The axon 2 cooperates with the welding groove 4.

[0025] A method for manufacturing a corrosion-resistant insulating mask, comprising the following steps:

[0026] S1, the welding surface of the axon 2 and the welding groove 4 is ultrasonically cleaned with alcohol, and dried with cold wind;

[0027] S2, using arc spraying to spray the welding surface to form a layer of metal film;

[0028] S3, sandblasting and roughening the metal film;

[0029] S4, take by weighing 114g of ni...

Embodiment 2

[0033] A corrosion-resistant insulating mask, including a mask 1 and a mask metal frame 3, the mask 1 includes a plurality of horizontal bars 7 and a plurality of vertical bars 6; between the horizontal bars 7 and the vertical bars 6 is a positive Cross-relationships and horizontal bars 7 and vertical bars 6 intersect to form a plurality of vapor deposition areas 5, each horizontal bar 7 and each vertical bar 6 are provided with axons 2 at both ends, and the mask plate metal frame 3 is provided with The axon 2 cooperates with the welding groove 4.

[0034] A method for manufacturing a corrosion-resistant insulating mask, comprising the above-mentioned axon 2 and the welding groove 4, comprising the following steps:

[0035] S1, the welding surface of the axon 2 and the welding groove 4 is ultrasonically cleaned with alcohol, and dried with cold wind;

[0036] S2, using arc spraying to spray the welding surface to form a layer of metal film;

[0037] S3, sandblasting and roug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com