Water diversion branch tunnel construction method capable of performing water feature recognition

A technology of feature identification and construction method, applied in water conservancy projects, artificial waterways, infrastructure projects, etc., can solve the problems of reduced structural strength, waste of manpower and material resources, increased cost and volume, etc., to achieve the effect of low strength and avoid strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

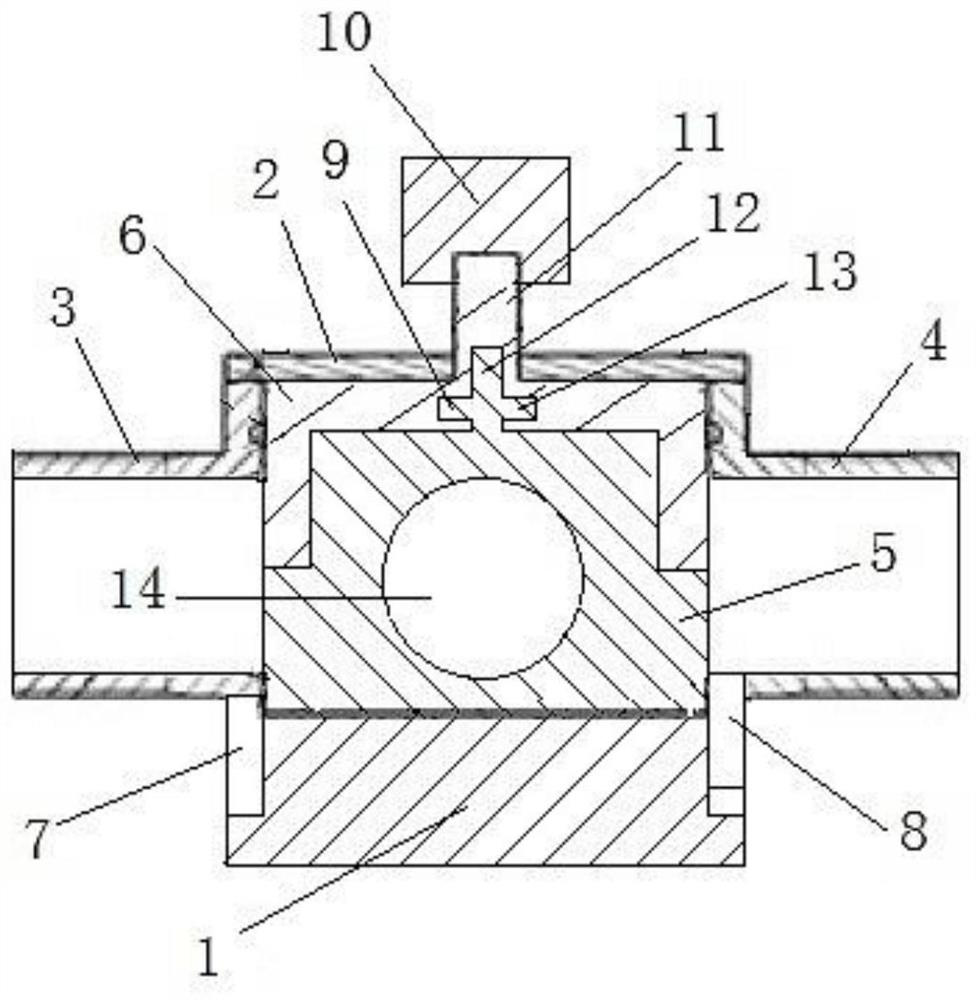

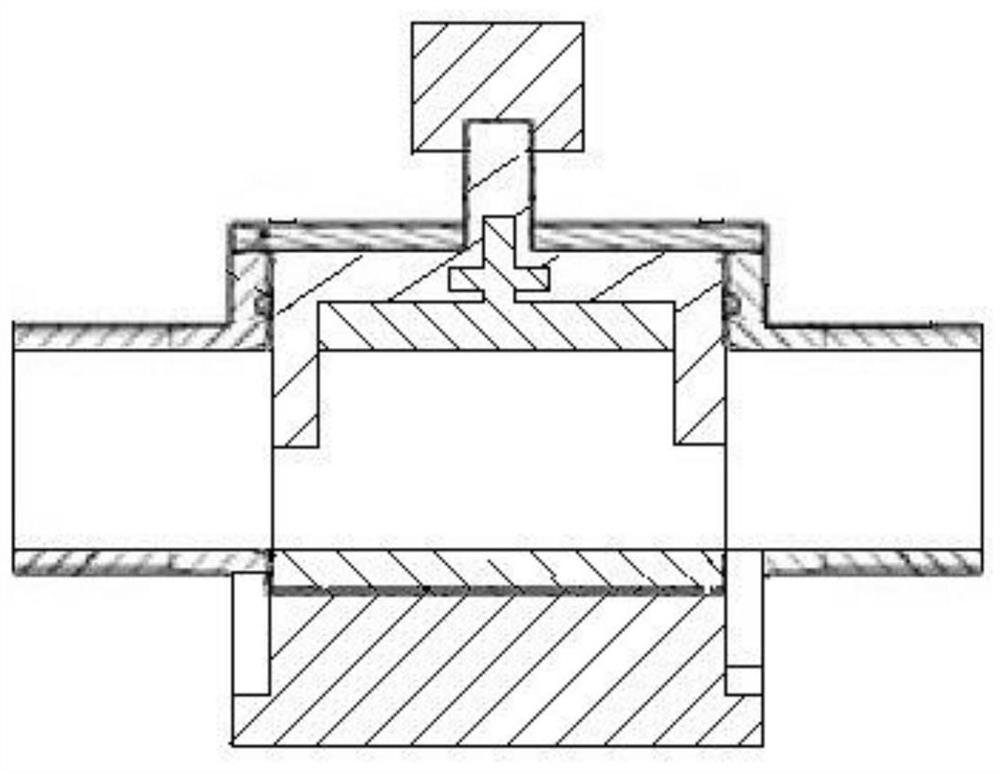

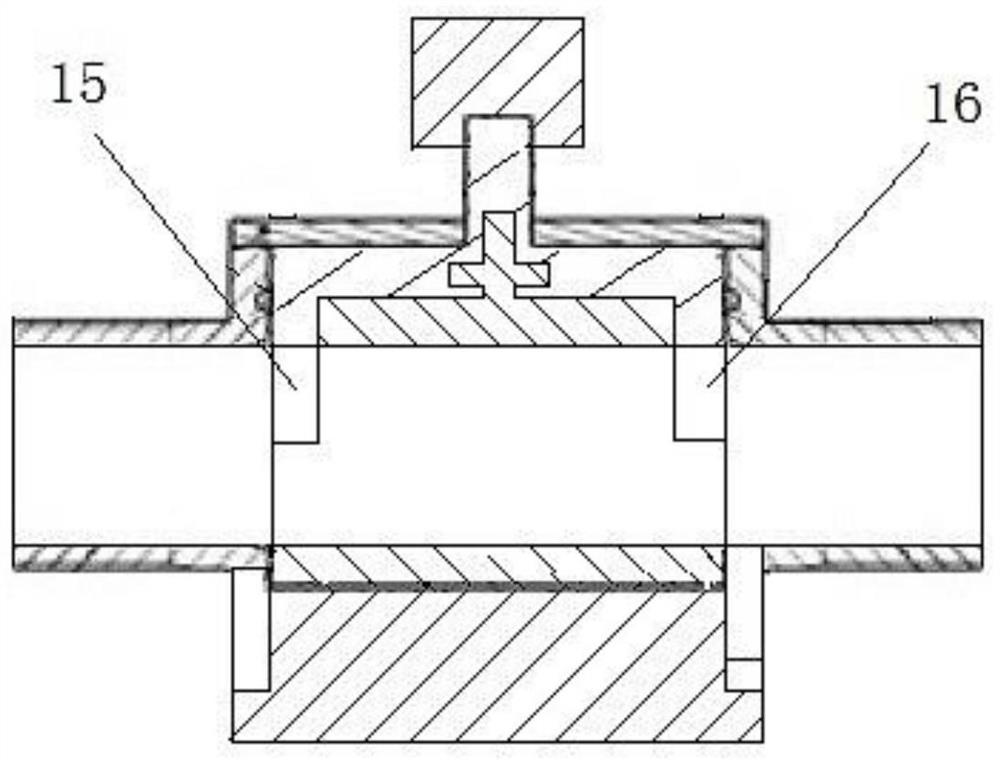

[0048] As shown in the figure: a water diversion branch tunnel construction method capable of water feature recognition, the construction method includes a grouting method, a groundwater feature recognition method; the grouting method includes a grouting method, a grout control method;

[0049] The pulping method includes: preparing the slurry according to the mass ratio of water: cement = 2:1, mixing it with a mixer after configuration, stirring the slurry periodically and intermittently, and the mixing time for each time should not be less than 2 minutes, and the mortar pump will mix well The slurry is pumped downstream through the delivery pipe;

[0050] The groundwater feature recognition method includes: a sampling and detection module is provided on the wall of the branch cave, and groundwater is introduced into the branch cave in a pilot test, and the water level of the connected groundwater reaches a predetermined water level line, and the water supply is stopped, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap