High-power five-cylinder drilling pump, drilling pump set, solid control system and drilling machine

A high-power, drilling pump technology, applied in the direction of multi-cylinder pumps, drilling equipment, pumps, etc., can solve the problems of mechanical loss, high cost of use, heavy operation and maintenance workload, etc., to meet transportation requirements, reduce size, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

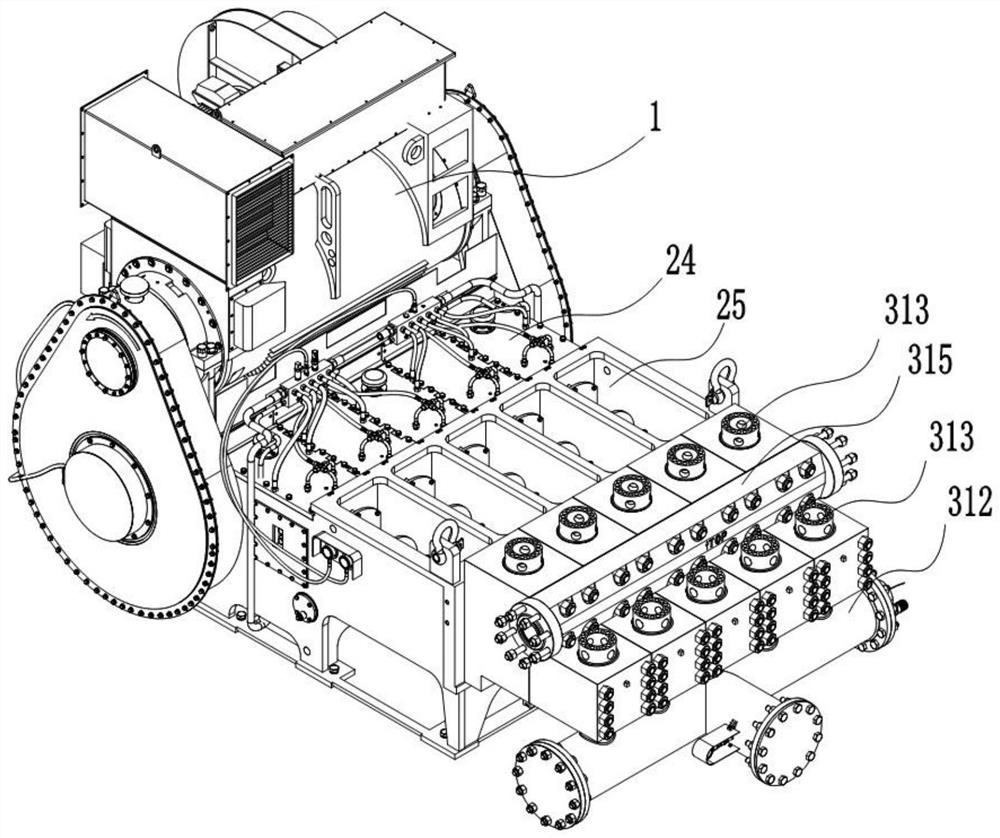

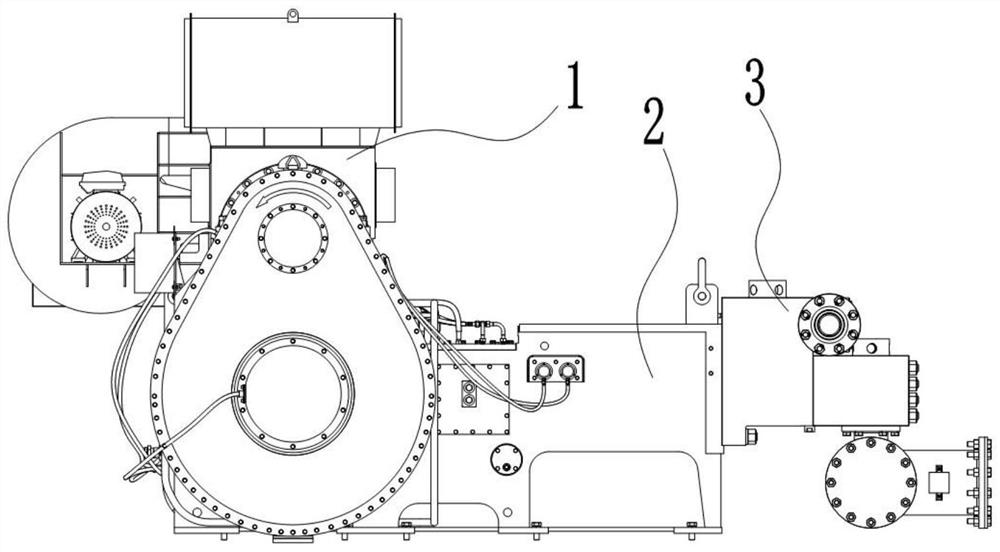

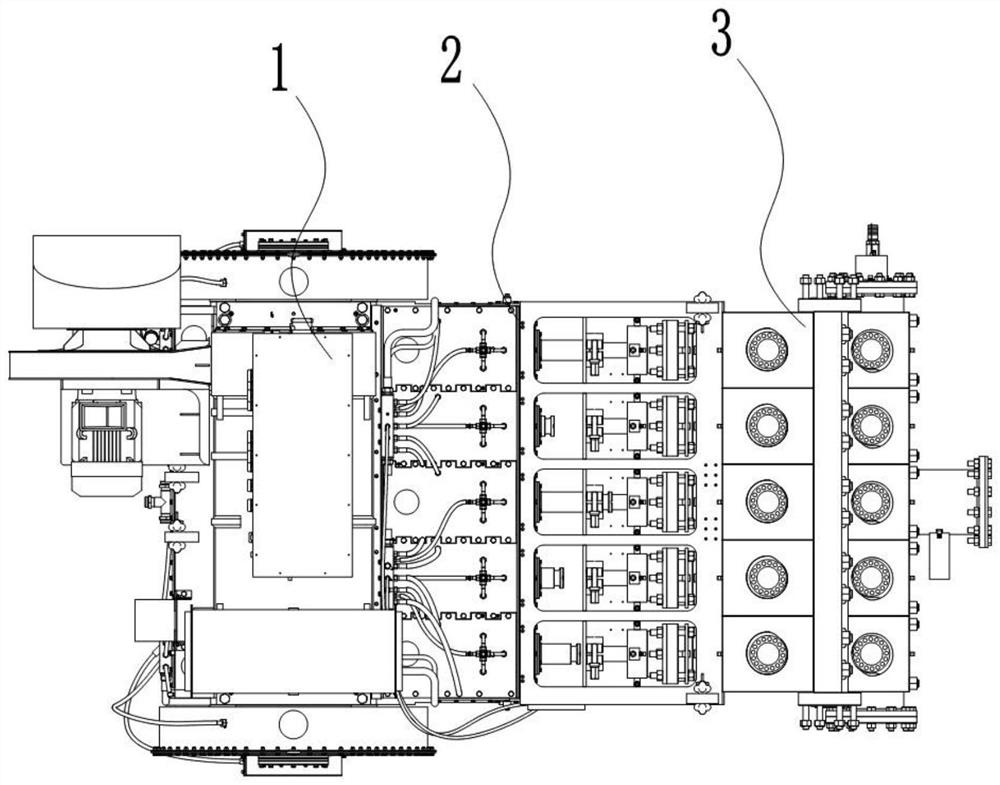

[0067] A high-power five-cylinder drilling pump, such as Figure 1 to Figure 15 As shown, it includes a transmission assembly 1, a power end assembly 2 and a fluid end assembly 3, the transmission assembly 1 is assembled and connected to the power end assembly 2, and the power end assembly 2 is connected to the fluid end assembly 3 , the traditional assembly 1 provides power, and drives the hydraulic end assembly 3 to work through the power end assembly 2;

[0068] The transmission assembly 1 includes a motor module 11, a transmission mechanism and a crank linkage mechanism, the motor module 11 is connected to and assembled with the crank linkage mechanism through the transmission mechanism, and the movement of the crank linkage mechanism is realized through the motor module 11;

[0069] The power end assembly 2 includes a plurality of power units, each of the power units is assembled and connected to the crank linkage mechanism, and the other end is independently equipped wit...

Embodiment 2

[0090] On the basis of the design of embodiment 1, in the design of the motor, it is different from embodiment 1, such as Figure 1 to Figure 6 As shown, the motor module 11 is an AC variable frequency motor. More preferably, the motor module is a three-phase squirrel-cage asynchronous motor.

[0091] In this embodiment, the AC variable frequency motor is directly driven, and the transmission efficiency is increased by about 3%-5% compared with the traditional structure; the performance parameters of the AC variable frequency motor are matched to meet the requirements of the drilling pump, and it is manufactured according to the electromechanical fusion design. The motor has long life, high reliability and high stability, and the on-site maintenance is convenient and quick. The motor makes full use of the constant power section to achieve super large displacement output. The maximum displacement of the direct drive drilling pump is 1.2-1.5 times that of the same level drilli...

Embodiment 3

[0093] On the basis of the design of Embodiment 1, as the assembly between the driving wheel 12 and the rotating shaft 17 is different, this embodiment does not adopt the interference fit method. Specifically, the driving wheel 12 is fixedly assembled on the rotating shaft through a key connection. 17 on.

[0094] As a specific description, in this embodiment, its structure can also achieve the effect of disassembly, but during the rotation of the rotor, it is a key as a component subjected to torque force. Although the effect can be achieved, its service life cannot be achieved. Effectively realize the effect of interference fit of the tapered surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com