Rotor compressor in side plug wiring mode

A rotor compressor and a compressor technology, which are applied in the field of rotor compressors, can solve the problems of limited installation space of the compressor cabin, unfavorable control of the axial space of the compressor, unfavorable design of refrigeration appliances, etc., so as to reduce the processing cost. , Conducive to the simple and convenient effect of space setting, installation and pipe placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

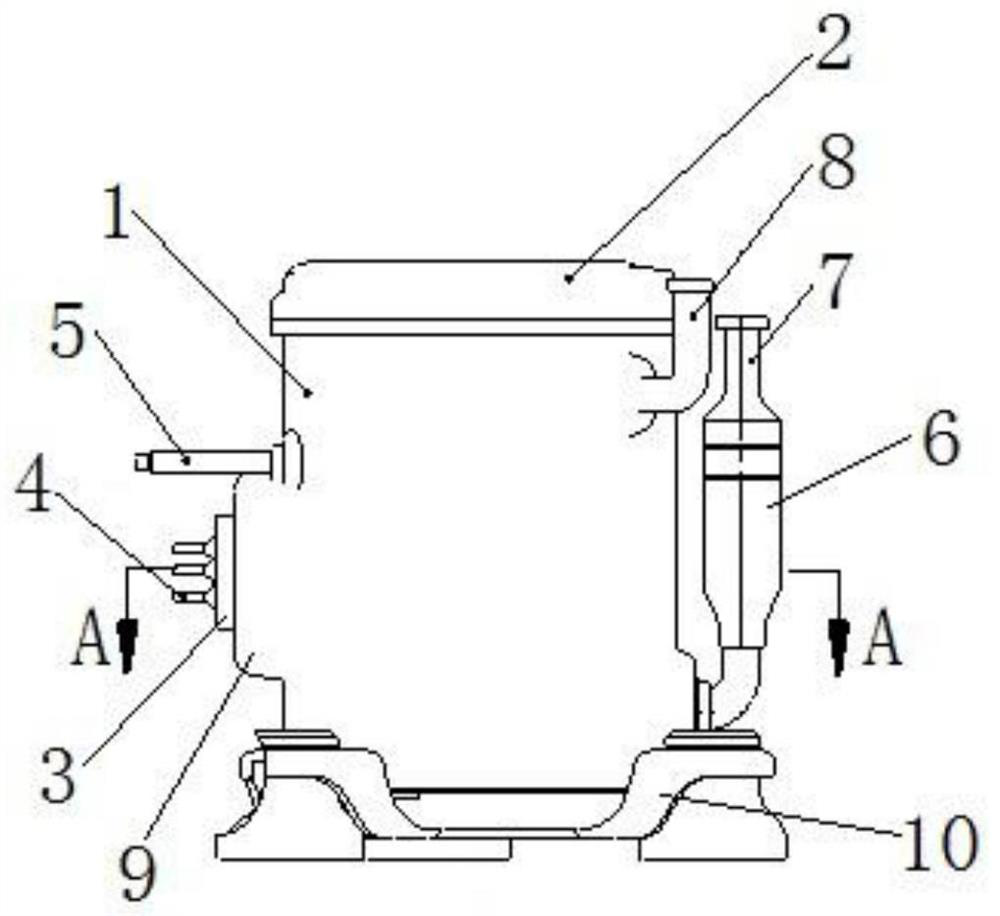

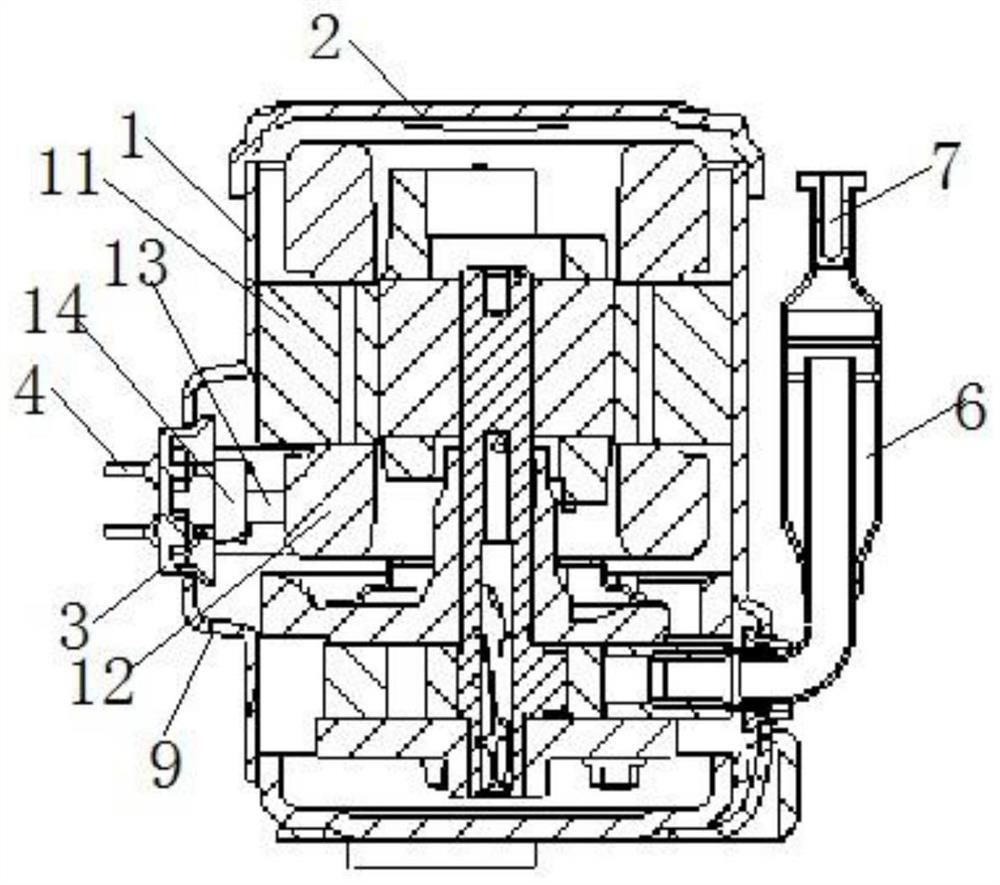

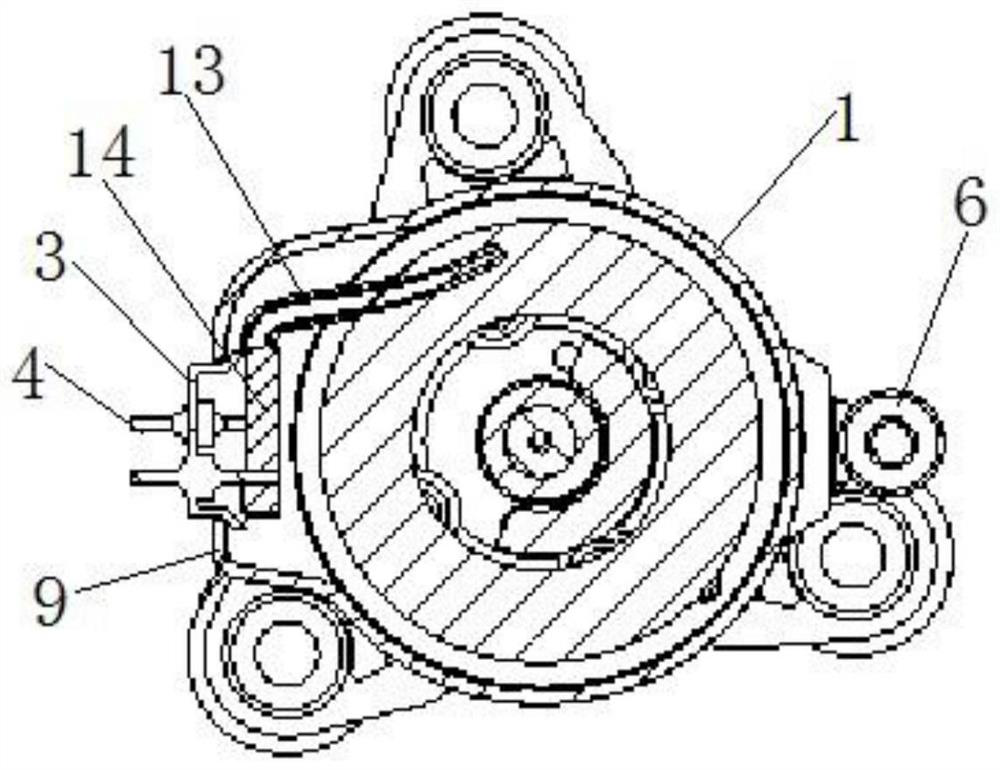

[0035] Such as Figure 1 to Figure 4 As shown, a rotary compressor in the form of side plug-in wires includes a compressor cylinder 1, an upper cover 2 is provided on the compressor cylinder 1, and a liquid accumulator is connected to the outer peripheral side of the compressor cylinder 1. 6. The compressor barrel 1 is provided with a motor, the upper cover 2 is a complete end cover without holes, and the outer peripheral side of the compressor barrel 1 is provided with a protruding cover 3, the cover There are several terminal posts 4 inside the body 3, one end of the terminal post 4 protrudes from the cover body 3, and the other end is connected to the lead wire 13 of the motor through a terminal block 14; the outer circumference of the compressor barrel 1 is also connected to There is an exhaust pipe 8 communicating with the interior, and the exhaust pipe 8 and the exposed part of the terminal post 4 all rotate around the central axis of the compressor barrel 1 at the large...

Embodiment 2

[0054] This embodiment provides a lead wire method for a rotary compressor.

[0055] A wiring method for a rotor compressor, comprising the following steps: After the motor is installed, lead the motor lead wires from the wire package 12 at the lower end of the stator core 11 of the motor, and then connect the lead wires 13 to the junction block 14 connection, the terminal block 14 is fixed and separates different leads, and then connected to different terminals 4, after the connection is completed, the cover body 3 is fixed at the opening to complete the package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com