A vacuum drying kettle for fine chemical production

It is a technology of vacuum drying and fine chemical industry, which is applied in drying chamber/container, drying solid material, dry goods processing, etc. It can solve the problems of unreliable vibration of equipment, failure to effectively guarantee products, and smaller volume of kettle body, etc., and achieve improvement Work efficiency, prevent vibration, ensure the effect of effective volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

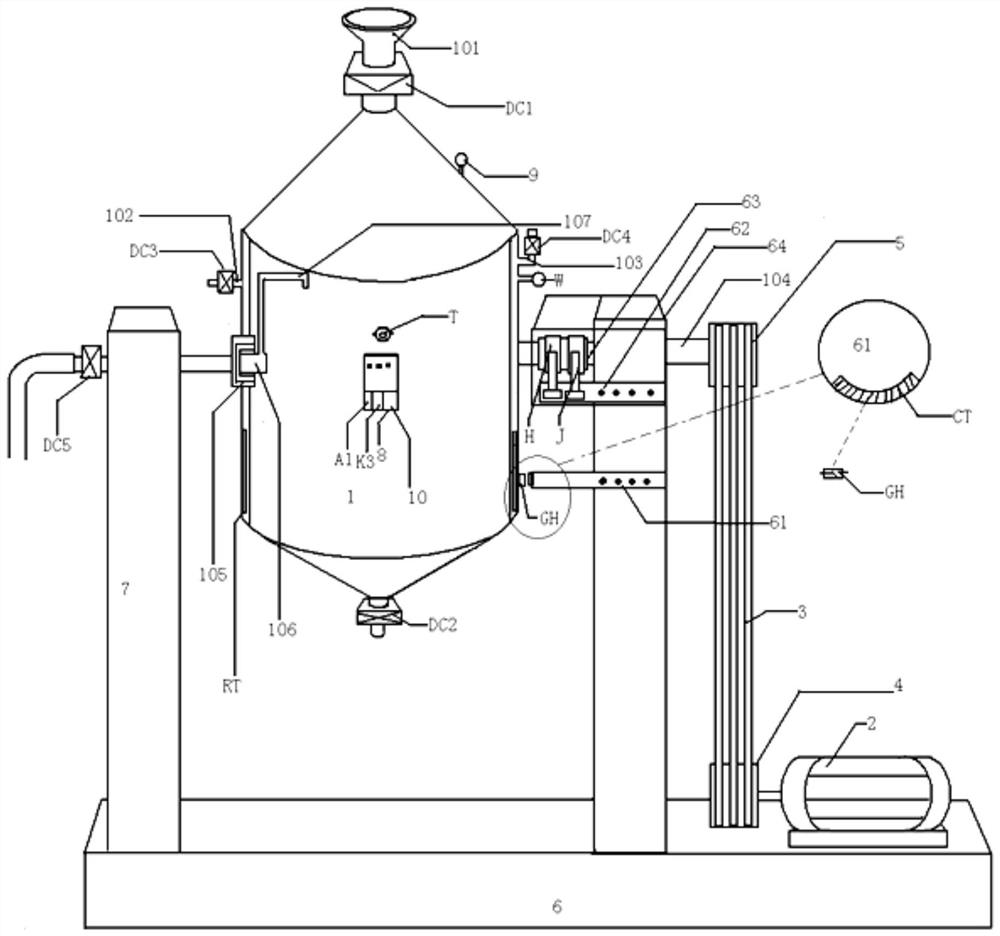

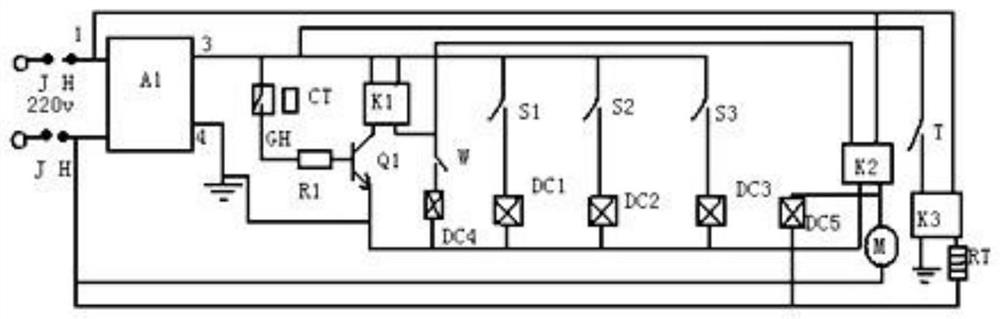

[0018] figure 1 As shown in , a vacuum drying kettle for fine chemical production includes a kettle body 1, a motor deceleration mechanism 2 (a finished product of a coaxial motor gear reducer, the power output shaft rotates at 6 revolutions per minute, and the power is 3KW), a conveyor belt 3 , Active pulley 4, driven pulley 5, support plate 6, support frame 7, solenoid valve, stabilized power supply A1, electric heating tube RT, power switch, pressure switch W; also has a detection mechanism, a temperature control mechanism, and a power supply mechanism; The upper and lower ends of the kettle body 1 are conical, the middle part is cylindrical, and there are five solenoid valves. One end of the first solenoid valve DC1 and the second solenoid valve DC2 and the upper and lower end connecting pipes of the kettle body 1 are respectively. By screw connection, the other end of the first solenoid valve DC1 is threadedly installed with a feeding bin 101 whose upper end is an open st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com