Method for temperature monitoring in cryo-electron microscopy

A technology of temperature sensor and electric current, applied in the direction of low temperature temperature measurement, low temperature thermostat, thermometer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

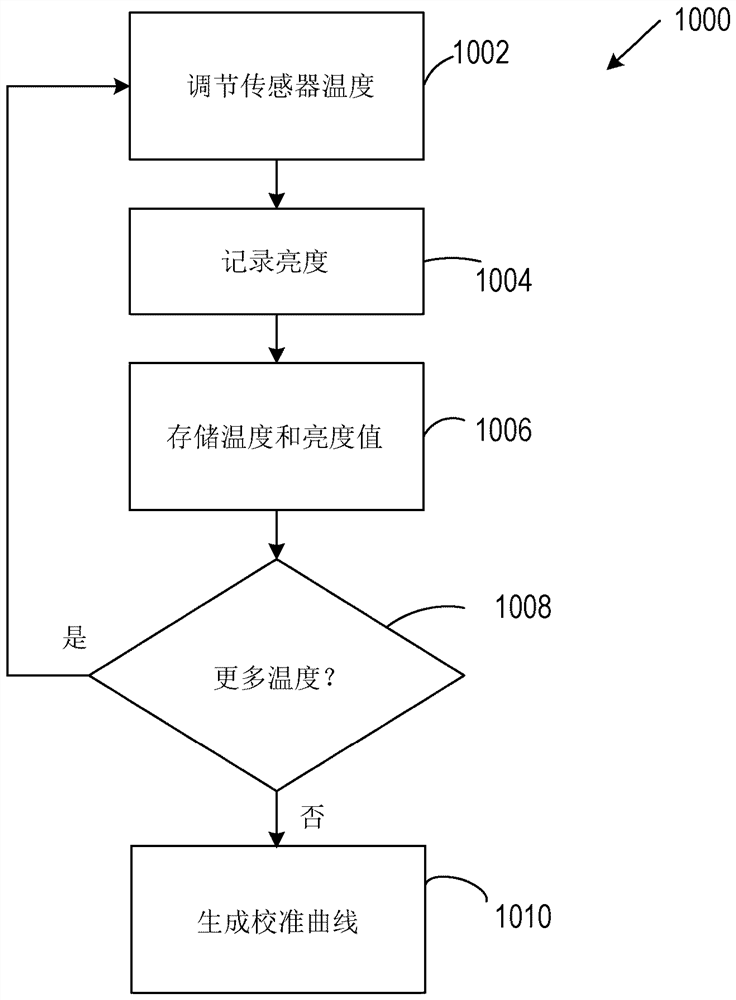

Method used

Image

Examples

example 1

[0026] refer to figure 1 , a representative electron microscope system 100 includes an electron emitter 104 operable to emit electrons from a tip 106 . Condenser lens 110 is positioned to generate an electron beam from the emitted electrons and to direct the electron beam generally along axis 119 . Beam deflector 111 is positioned along axis 119 and can selectively deflect or scan the electron beam relative to sample S and generate deflected beam 130 . The sample S is positioned on a sample stage 140, which allows for translation and tilt adjustment of the sample S. The sample S is typically fixed to or formed on a sample holder 144, which may include a sensing region 142 formed from HTSC or other sensor material. Objective lens 132 is positioned to direct the electron beam from sample S to detector 146 . In some examples, one or more detectors, such as detector 148, are positioned to detect the electron beam or radiation responsive to the electron beam, such as secondary e...

example 2

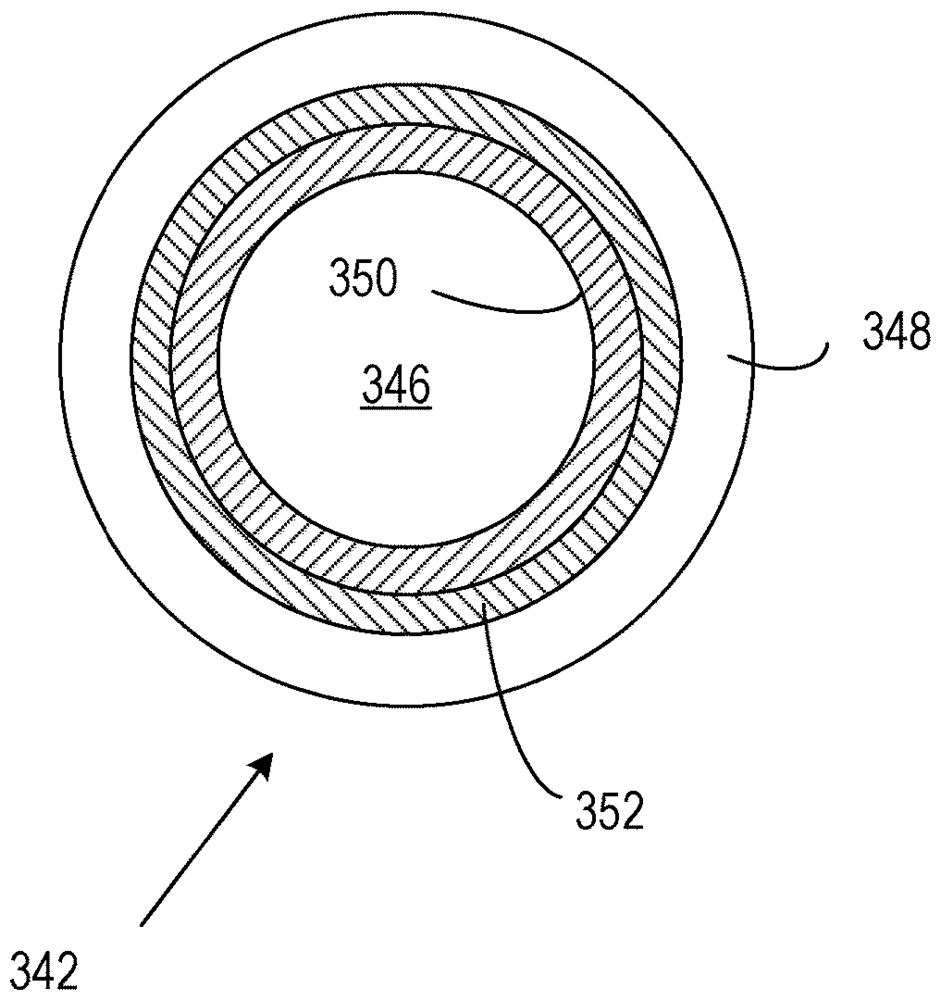

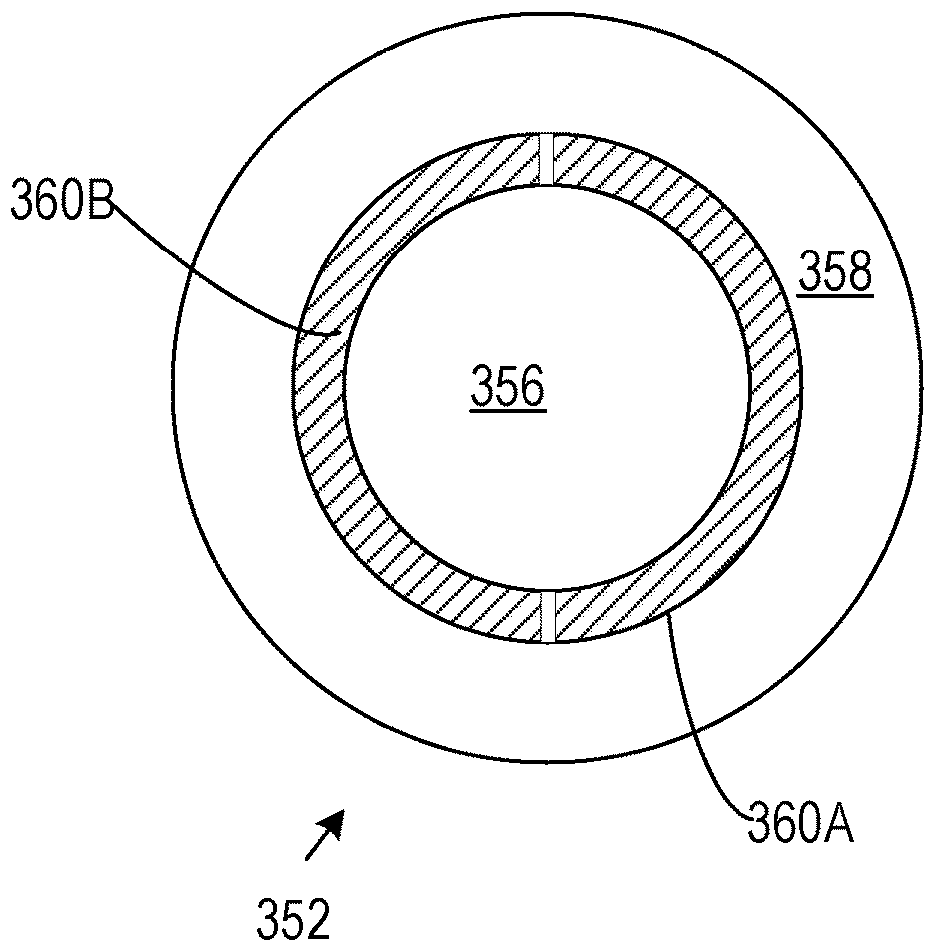

[0035] exist figure 1 A representative sample holder used in the system 900 in Figures 9A-9B shown in . A perforated carbon film 904 is positioned to support a sample 903 (shown as one or more cells 902 ), and in turn is positioned on a metal grid 906 . Metal ring 908 is coupled to the perimeter of metal grid 906 . The temperature sensor material 910 is positioned at or on the metal ring 908, but may be positioned in other ways as discussed below.

example 3

[0037] refer to Figure 3A , a representative sample holder 380 includes a conductive grid 382 typically formed of a conductive perimeter ring 384, typically Cu, Rh, Au, or other metal. The regions between the gridlines may include a thin film, such as an amorphous carbon film with a plurality of holes or perforations. Such membranes are often referred to as "porous carbon membranes" and the samples to be studied can typically be fixed on the membrane by snap freezing. A temperature sensor 386 is positioned on the perimeter ring 384, and additional sensors may be provided on the perimeter ring 384, the conductive grid 382, or the area between the grid lines. The following examples generally refer to the configuration of the temperature sensor, and details of sample mounting of such carbon films are omitted in some cases for ease of illustration.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap