A method of rtcp parameter calibration of five-axis machine tool based on r-test

A parameter calibration, machine tool technology, applied in computer control, program control, instruments, etc., can solve the problems of incomplete measurement results, difficult to represent efficiency, influence of calculation accuracy, etc., to achieve easy learning and use, avoid human errors, geometric characteristics obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0046] An R-test-based five-axis machine tool RTCP parameter calibration method, comprising the following steps:

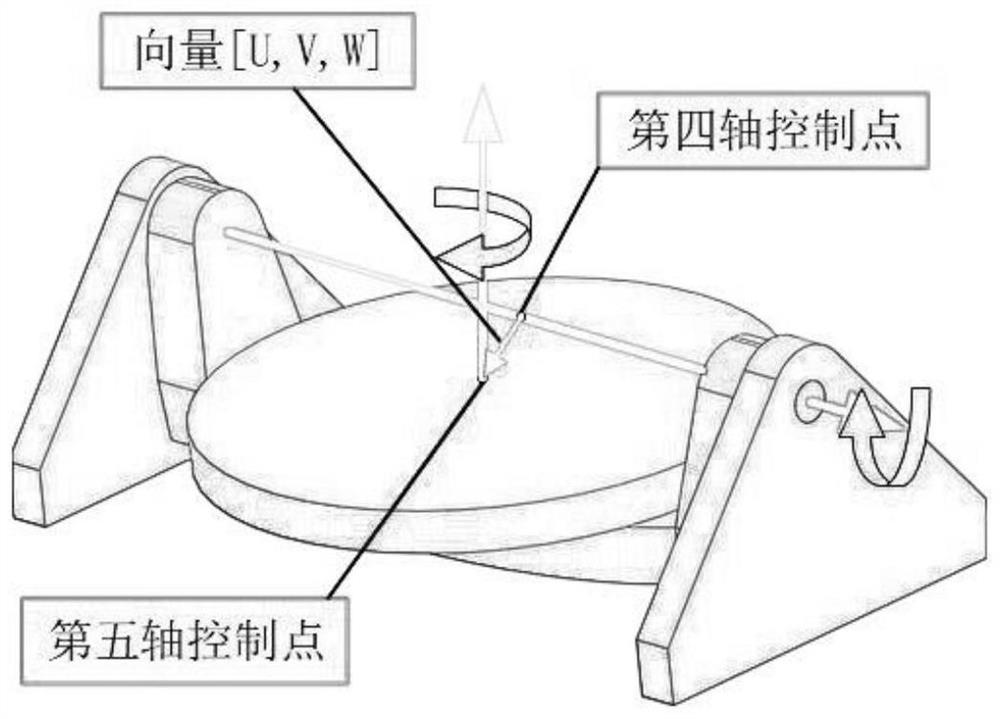

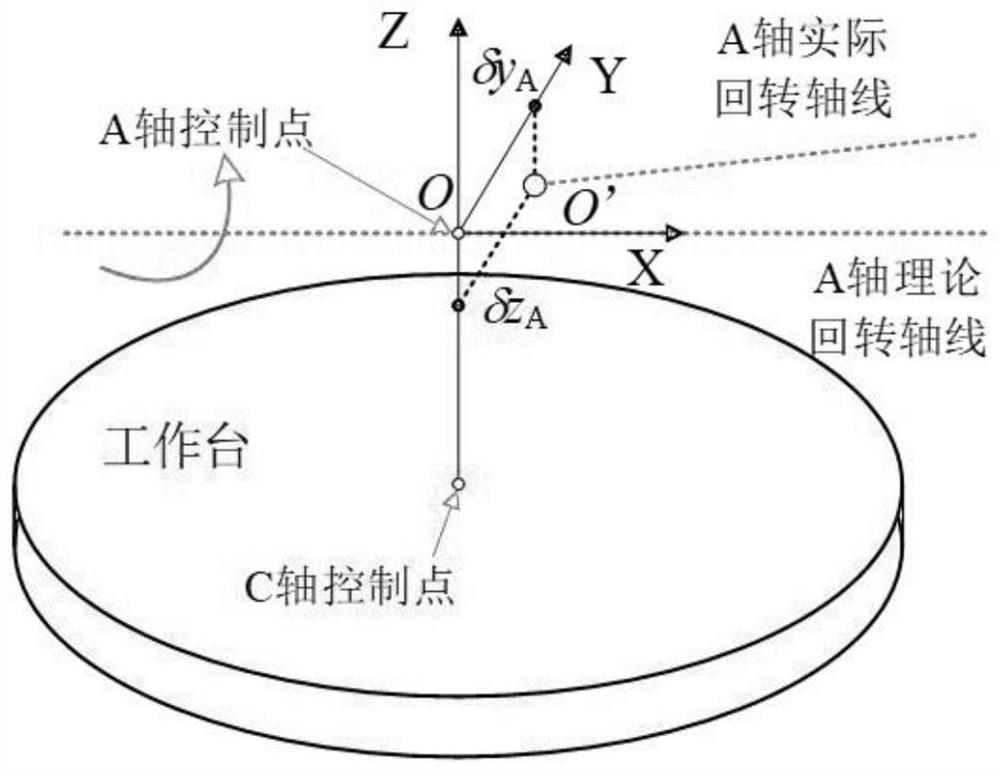

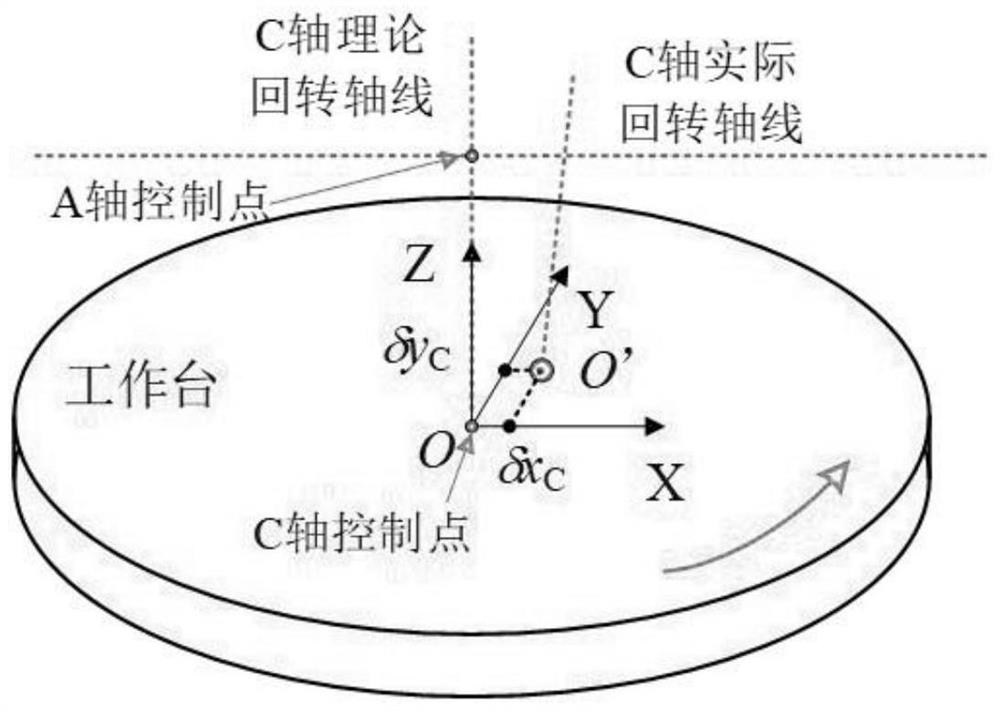

[0047] 1) Define the error term that affects the RTCP parameters, refer to figure 1 , figure 1 The vector from the control point of the fourth axis of the machine tool to the control point of the fifth axis in this embodiment, that is, the schematic diagram of the RTCP parameters; the fourth axis is the A axis, and the fourth axis control point is the center point of the rotation axis of the A axis; the fifth axis is the C axis axis, the control point of the fifth axis is the intersection of the rotation axis of the C axis and the table plane; with the machine tool coordinate system as a reference, the A axis and the C axis are regarded as independent units; refer to figure 2 , the two displacement errors of the fourth axis A-axis contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com