Defect identification method

A defect recognition and defect technology, applied in character and pattern recognition, image data processing, instruments, etc., can solve a large number of problems such as manual intervention, false detection, defect missed detection, etc., to increase detection efficiency, improve detection accuracy, and reduce manpower cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

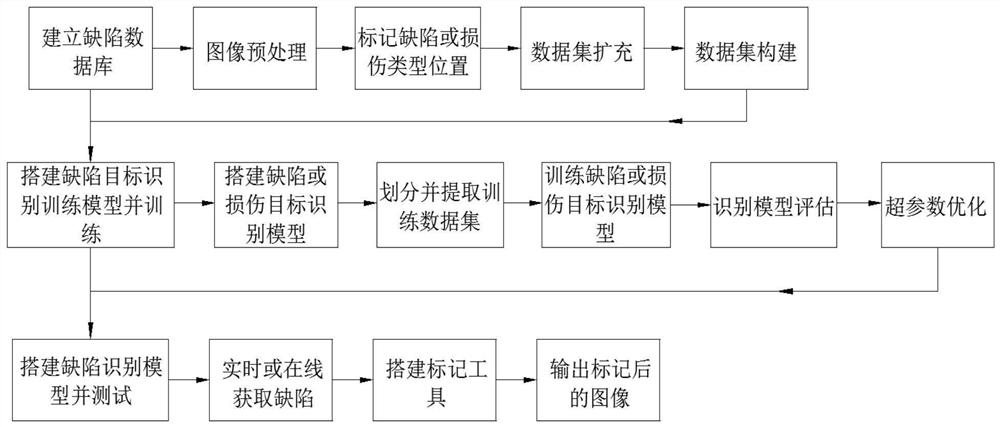

[0013] see figure 1 As shown, a defect identification method includes the following steps:

[0014] S1. Establish a defect or damage database;

[0015] S2. Build and train a defect or damaged target recognition training model;

[0016] S3. Build and test the defect or damage recognition model, extract the cluster gray scale and morphological features of the target detection range, and judge the defect type and qualification standard.

[0017] The defect detection in this embodiment is a necessary link in industrial manufacturing, which ensures the qualified rate of products and improves the stability of quality. It can be widely used in various industrial scenarios, including metal products and welding application scenarios. It is suitable for defect detection, material flaw detection and specific material identification in any industry using X-ray, neutron imaging, and acoustic wave imaging. The clustering gray level and morphological features are mainly determined accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com