A heat measurement pretreatment and storage monitoring system for filaments of cyclotron traveling wave tubes

A traveling wave tube and pretreatment technology, applied in the manufacture of discharge tubes/lamps, electrode system manufacturing, measurement/testing during the manufacturing process, etc., can solve the problems of lack of convenience and timeliness, and ensure the integrity of functions High efficiency, simplification of operation procedures, saving time and cumbersome procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to more clearly understand the above objects, features and advantages of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

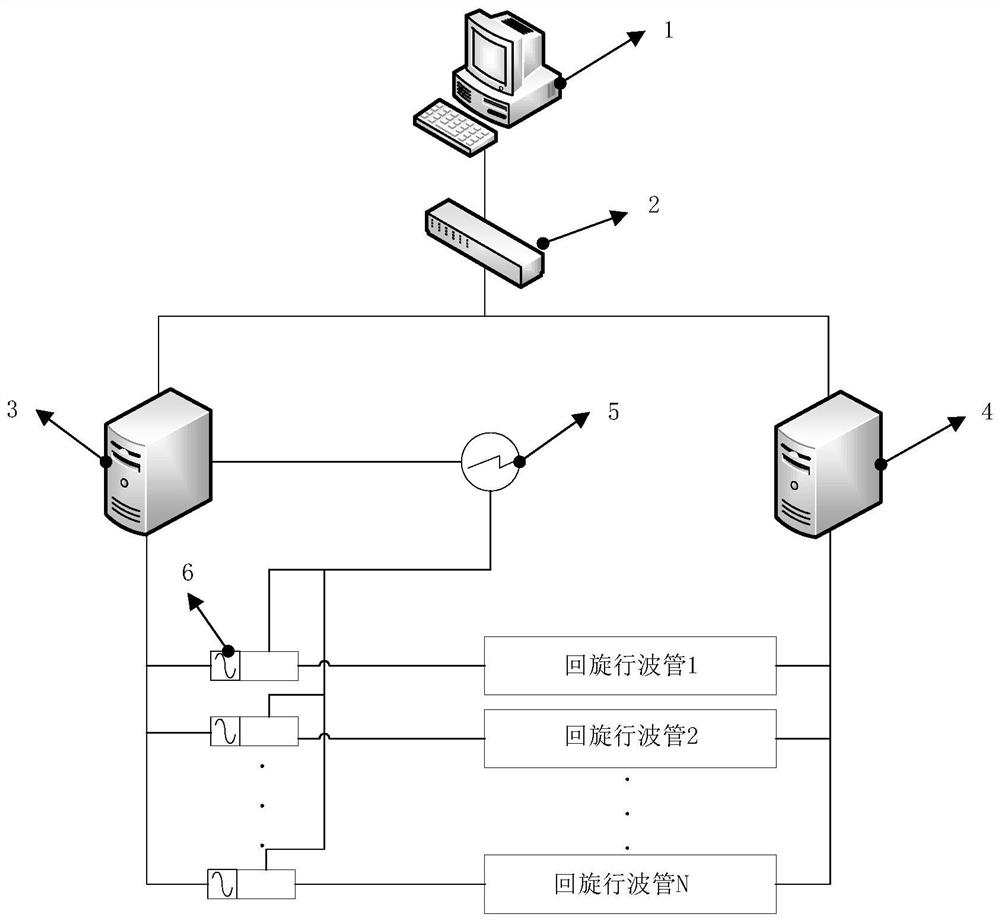

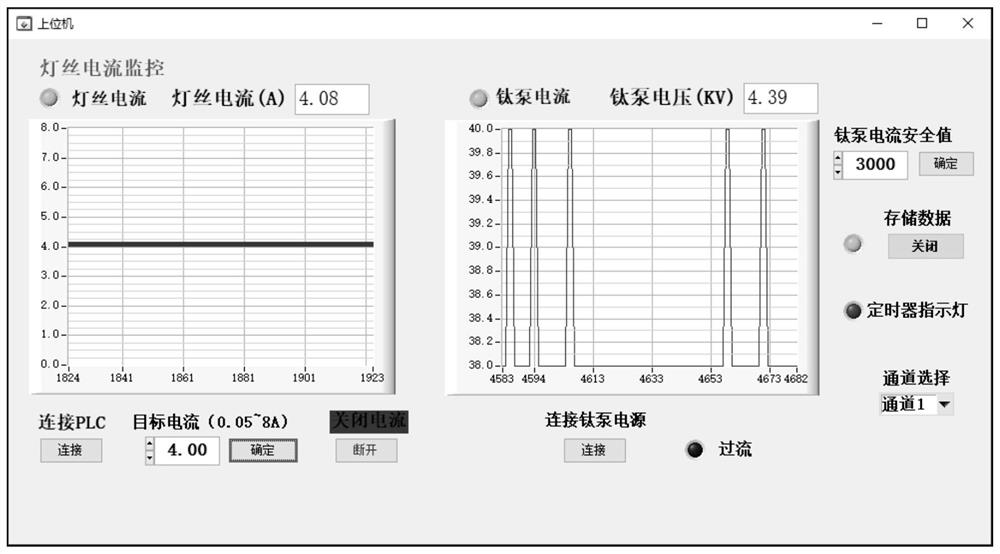

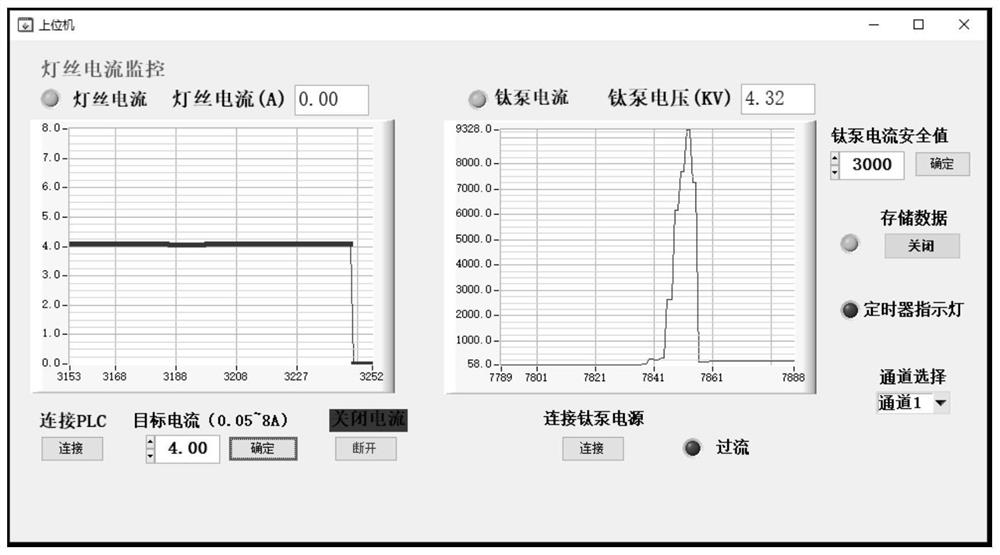

[0021] like figure 1 As shown, the PLC and the power supply of the titanium pump are connected to the PC through a switch. With the PC as the client, the PLC and the titanium pump power supply as the server, the PC client sends a connection request. After the connection is successful, the PLC and the titanium pump power supply will continue to provide data feedback. The PC client collects all the data, and makes the host computer through LabWindows / CVI to visualize the received data. At the same time, the PC client is set with a titanium pump abnormal coefficient threshold. When the titanium pump voltage and current data fed back to the PC client by the titanium pump power supply exceeds the titanium pump abnormal coefficient threshold, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com